Here you will find:

Use the buttons below to skip to a specific section.

EN PH 131

Simulations:

Pool

This simulation simulates the collisions in a game of pool.

Conservation of momentum and rolling resistances apply.

MEC E 250

Tutorials:

Simulations:

Pool

This simulation simulates the collisions in a game of pool.

Conservation of momentum and rolling resistances apply.

MEC E 260

Tutorials:

Car Motion

This tutorial shows how to simulate the motion of a car. This tutorial covers the use of appropriate mates, the addition of a simulation motor, and the execution of a motion simulation.

Basketball Throw

This tutorial shows how to simulate the trajectory of an object, and how to use a design study to find success cases.

Trebuchet Shot

This tutorial shows how to simulate event based motion. The events in the tutorial involve turning on/off mates, forces and motors.

Friction

This tutorial shows how to modify coefficients of friction in SOLIDWORKS motion. It also compares the SOLIDWORKS motion solution to the analytical solution of a problem where a car slips while climbing a hill.

Key Steps: running a Motion Study, running a Design Study, comparing numerical and analytical solutions.

Time: 95 minutes

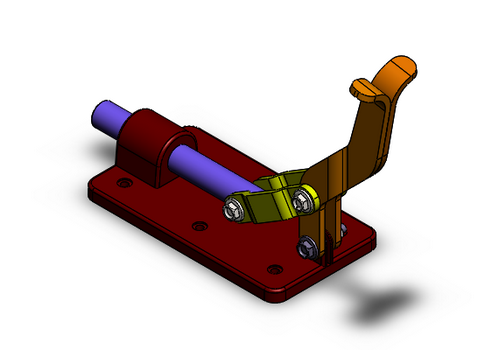

Plunger

This tutorial describes how to run a motion analysis on a pre-existing assembly.

Time: 90 Minutes

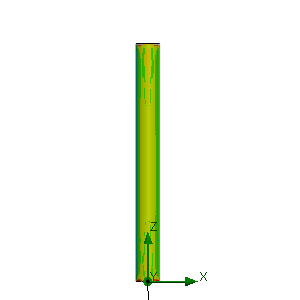

Shaft Deflection

This tutorial shows how to use SOLIDWORKS to simulate the deflection and angular twist of a stepped shaft. You will also learn how to extract meaningful simulation data using Excel.

Key Features: Reference Planes, Split Lines, Mesh Control, Bearing Fixtures, Remote Loads, Torque, Distributed Forces.

Time: 45 Minutes

MEC E 265

Tutorials:

Guide to SOLIDWORKS

This tutorial is an introduction to the SOLIDWORKS tutorials and the SOLIDWORKS interface. This tutorial reviews essential SOLIDWORKS terminology, controls, and features.

Time: 15 Minutes

Parts

This tutorial demonstrates the creation of a SOLIDWORKS part.

Key Features: Sketch, Extruded Base/Boss, Extruded Cut, Hole Wizard, Chamfer, Shell, Fillet, editing materials, Section View.

Time: 30 Minutes

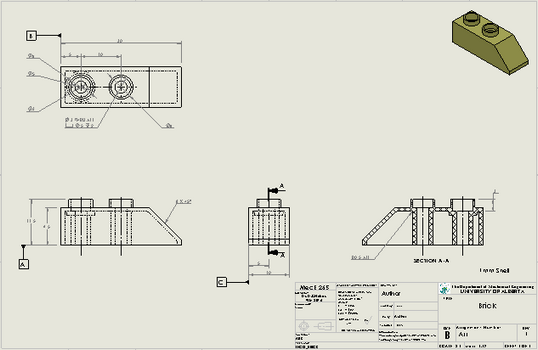

Drawings

This tutorial demonstrates the creation of an engineering drawing from a solid model.

Key Features: Make Drawing from Part, editing views, Centerline, Center Mark, Smart Dimension, Datum, Note, PDF export, PackNGo.

Time: 45 Minutes

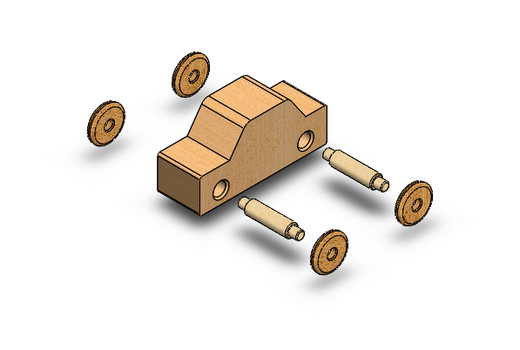

Assemblies

This tutorial demonstrates the creation of a SOLIDWORKS assembly and of the appropriate engineering drawings.

Key Steps: create assembly and subassemblies, make exploded view, create assembly drawing.

Time: 60 Minutes

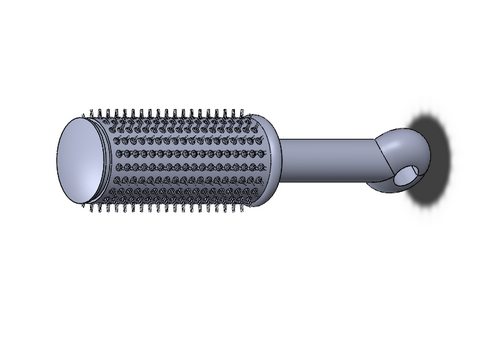

Revolves

This tutorial demonstrates the use of revolve-style features.

Key Features: Revolved Boss/Base, Revolved Cut, Swept Boss/Base, Mirror, Linear Pattern, Circular Pattern.

Time: 45 Minutes

Laser Cutter

This tutorial demonstrates the use the Mec E shop's laser cutter to make a 3D object from flat material stock.

Key Steps: add offset configuration to model and drawing, create laser cutter drawing.

Time: 15 Minutes

Design Tables

This tutorial demonstrates the use of a design table in EXCEL to control the size and configuration of a SOLIDWORKS part.

Key Steps: name features/dimensions, insert design table, add configurations.

Time: 30 Minutes

Sheet Metal

SOLIDWORKS has specific toolboxes that have been developed to allow the design of complex shapes using a specific manufacturing approach.

This tutorial explains how to use create parts using the Sheet Metal tools.

Time: 45 Minutes

3D Printing

Additive manufacturing (3D printing) is a new manufacturing technique that allows many manufacturing constraints to be removed.

This tutorial walks through how to create parts for 3D printing.

Time: 45 Minutes

Tolerancing

Solid models are built in the virtual world where all dimenisons are mathmatically perfect.

This tutorial explains the concepts and uses of tolerancing to allow components to be manufacture to achieve a function.

Time: 30 Minutes

CIV E 270

Tutorials:

Basic Cantilever Beam

This tutorial introduces beam simulation in SOLIDWORKS.You will learn how to solve for beam deflection using FEA methods and compare the results to a theoretical solution.

Key Features: SOLIDWORKS Simulation, Fixed Geometry, Force

Time: 30 minutes

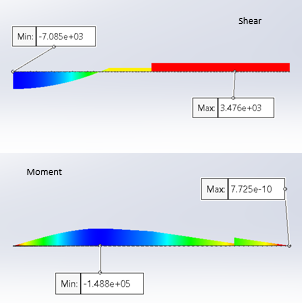

Shear and Bending

This tutorial demonstrates the analysis of forces and bending moments in a beam. It also shows how to generate shear and moment diagrams in a Simulation.

Key Features: Simulation using Beam Elements, Reference Geometry, Immovable Fixtures, Non-Uniform Distributed Forces, Moments.

Time: 45 minutes

Shear

This tutorial explores the distribution of shear throughout a beam loaded in bending, and techniques to obtain and graph meaningful data from the simulation.

Key Steps: Creating a split line through the beam to measure shear stress, changing beam configurations, comparing simulation results with an analytical solution.

Time: 30 minutes.

Simulations:

MEC E 360

Tutorials:

Bolted Connection

In this tutorial, you will analyze four methods to simulate bolted connections using FEA Simulation in SOLIDWORKS.

Key Features: SOLIDWORKS Simulation, Fixed Geometry, Force, Bolt Connection, Global Interaction

Time: 30 minutes

Shaft Deflection

This tutorial shows how to use SOLIDWORKS to simulate the deflection and angular twist of a stepped shaft. You will also learn how to extract meaningful simulation data using Excel.

Key Features: Reference Planes, Split Lines, Mesh Control, Bearing Fixtures, Remote Loads, Torque, Distributed Forces.

Time: 45 Minutes

MEC E 362

Tutorials:

Resources:

MEC E 371/463

Tutorials:

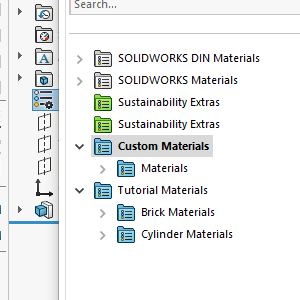

Custom Materials

Many SOLIDWORKS simulations depend on the material properties of the part or assembly being examined.

This tutorial will show you how to edit these properties, as well as how to create, import and export custom materials and fluids.

Time: 60 Minutes

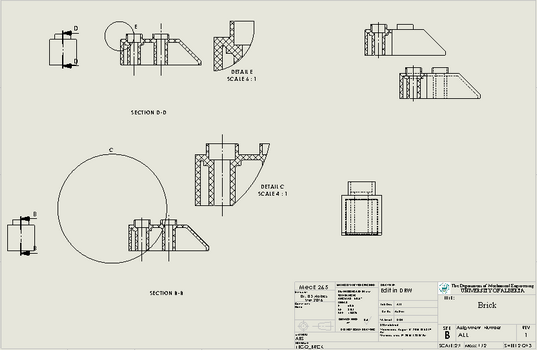

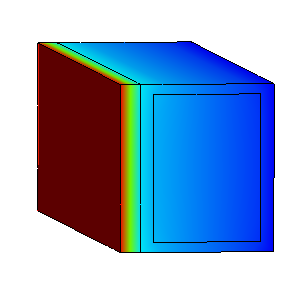

Brick Wall Heat Transfer

Heat transfer is an important engineering problem. This tutorial shows you how to set up a steady-state heat transfer simulation in SOLIDWORKS.

Time: 60 Minutes

Critical Radius

Design studies can be used together with heat transfer simulations to examine many scenarios in a relatively short time. This tutorial examines the temperate of a copper wire with various thicknesses of insulation.

Time: 60 Minutes

Transient Conduction

Building off of previous concepts, transient heat transfer can be modelled in SolidWorks. This tutorial will show you how to set up, run, and analyze transient thermal studies for conduction through an egg over time.

Time: 75 Minutes

MEC E 331/430

Tutorials:

Cylinder Flow Introduction

This tutorial will introduce you to using SOLIDWORKS' flow simulation add-in. You will use the Flow Wizard to create a new simulation project, then use the simulation to determine the lift and drag coefficients of the flow over a cylinder.

Time: 30 Minutes

Cylinder Flow Parametric

In order to quickly analyse a number of flow scenarios, SOLIDOWORKS allows you to do a Parametric Study. In this tutorial, you will find the lift and drag coefficients of flow over a cylinder at a number of different flow velocities.

Time: 30 Minutes

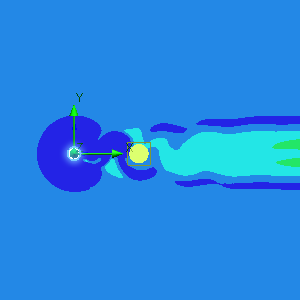

Cylinder Flow Transient

A transient analysis allows you to observe the development of various fluid phenomena. In this tutorial, you will examine the vortices that are generated as water flows over a cylinder.

Time: 45 Minutes

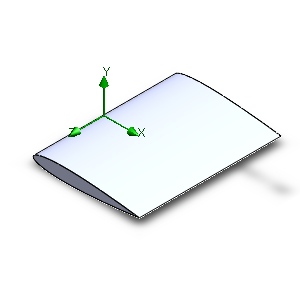

Airfoil

This tutorial combines the knowledge we learned from the previous tutorial, we will perform a simulation on a NACA airfoil and see if our simulation results is close to the xfoil data.

Time: 45 Minutes

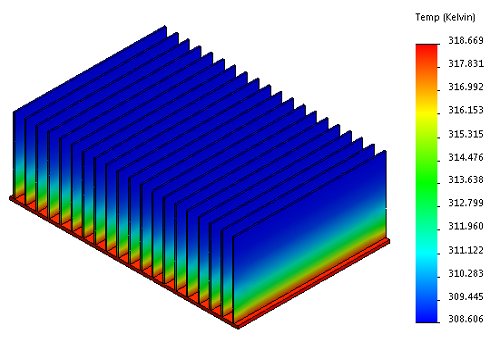

Pin Fin (CFD)

In this tutorial will use the flow simulation to capture the heat transfer coefficient distribution on the surface, as well as examining the average heat transfer coefficient used in the fin equation tutorial. Complete the Pin Fin (Heat Transfer) Tutorial before starting this tutorial.

Time: 30 Minutes

Videos:

Understand the defining characteristics of each type of flow and how to calculate its Reynolds Number.

Define Lagrangian and Eulerian descriptions in Fluid Mechanics and their purpose and applications in engineering.

Define four different types of flow patterns in Fluid Mechanics.

How to get the equation of a streamline from a velocity field using its definition.

How to derive the equation, its limitations and required conditions, and 2 other forms of The Bernoulli Equation.

Simulations:

Terminal Velocity

Simulation of a circle falling through a variable fluid. The density of the fluid and circle can be changed. The circle's drag coefficient and radius can also be changed.

TASKS/MC Questions:

A quiz is located near the bottom with a combination of questions and tasks.

Buoyancy

Simulation of a circle floating/sinking in a fluid. The fluid/circle's density can be changed. The simulation is accompanied by a live plot that shows the forces acting on the circle.

TASKS/MC Questions:

A quiz is located near the bottom with a combination of questions and tasks.

EGL/HGL

Simulation of Energy Grade Lines and Hydraulic Grade Lines. The pipeline can be populated with draggable components such as pipes, pumps, turbines, etc. SOLIDWORKS Parts for each component is provided.

Note: Simplified with Mass Flow Rate as Input.

MEC E 460/468

Tutorials:

FEA Elements

This tutorial explores the three types of elements that can be used in SOLIDWORKS simulation: Beam, Shell, and 3D.

Key Steps: Configuring and running a SOLIDWORKS simulation study, specifying mesh element type, comparing results.

Time: 30 minutes

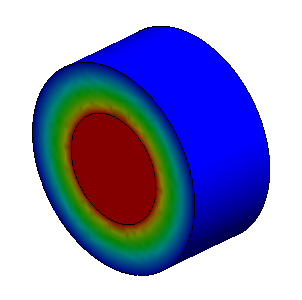

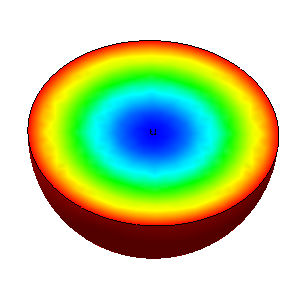

Mesh Refinement

This tutorial shows how to apply local mesh refinement and how this can be useful in obtaining more accurate simulation results around specific geometry.

Key Steps: Creating a part with multiple solid bodies, creating mesh control points, exporting specific data.

Time: 45 minutes

Remote Loads

In this tutorial, you will learn how to run static simulations on a multi-part beam. Then, you will run an equivalent simulation on a simplified, single part structure using the Remote Load feature in SOLIDWORKS.

Key Features: SOLIDWORKS Simulation, Fixed Geometry, Force, Remote Load

Time: 20 Minutes