Vehicle Projects

At the Energy Mechatronics Lab (EML), we focus on advancing the efficiency and development of vehicles powered by a wide range of fuel sources and powertrain technologies. Our research spans hydrogen fuel cells, dual-fuel systems, advanced diesel engines, hybrid electric, and battery-electric powertrains, all with the goal of driving innovation in sustainable, reliable, and high-performance transportation.

EML specializes in the instrumentation, testing, and analysis of emerging vehicle technologies — from light-duty passenger cars to heavy-duty commercial trucks and buses. To date, we have led third-party evaluations of more than $40 million in commercial vehicle technologies, including electric, hybrid electric, fuel cell, and hydrogen-diesel platforms, benchmarking them against conventional diesel and gasoline powertrains. These works have been supported by the automotive industry along with the federal and provincial funding agencies committed to advancing alternative vehicle technologies suited to the Canadian climate and ecosystem.

AZEFF (Alberta Zero Emission Fuel Fleet)

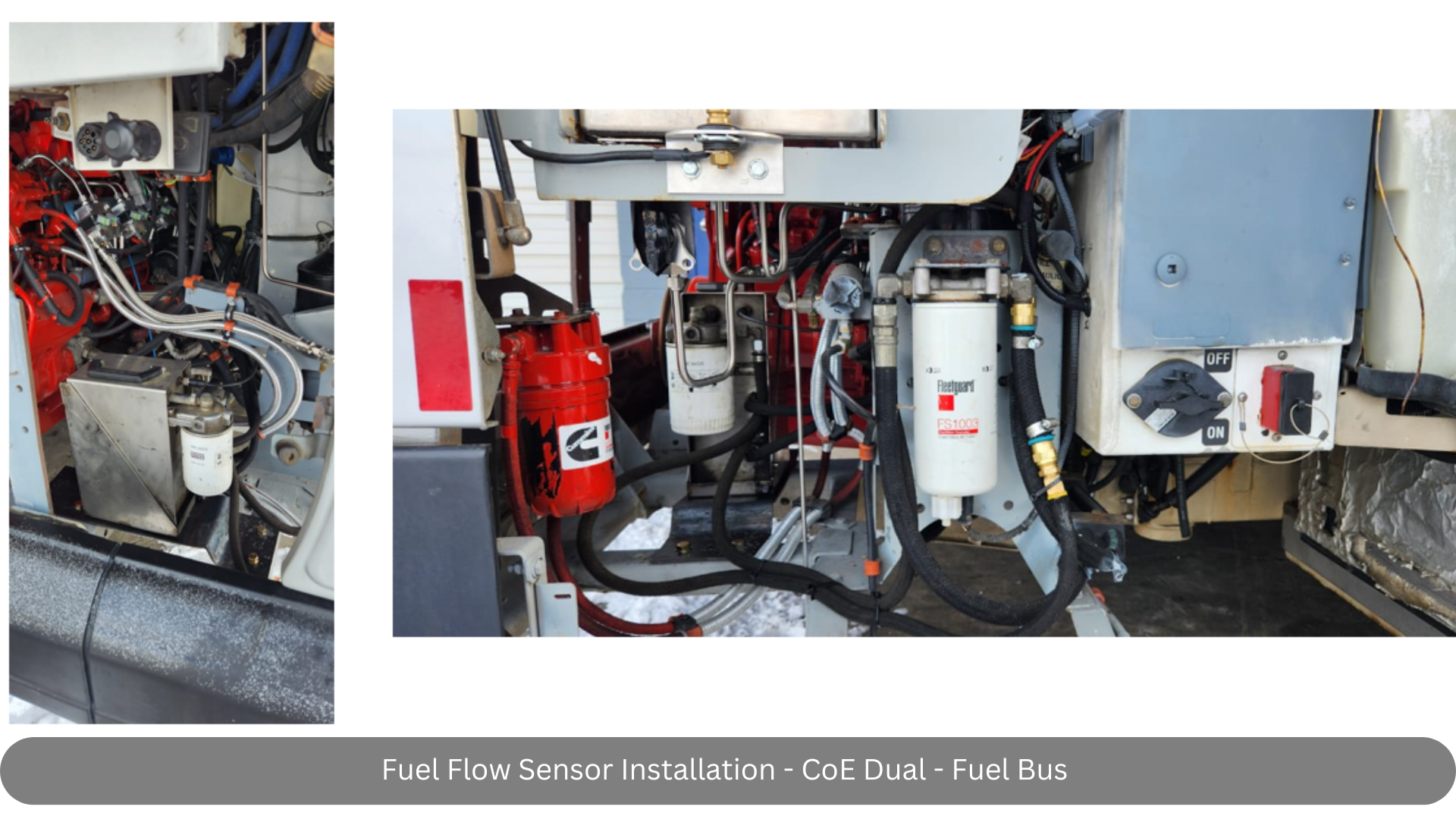

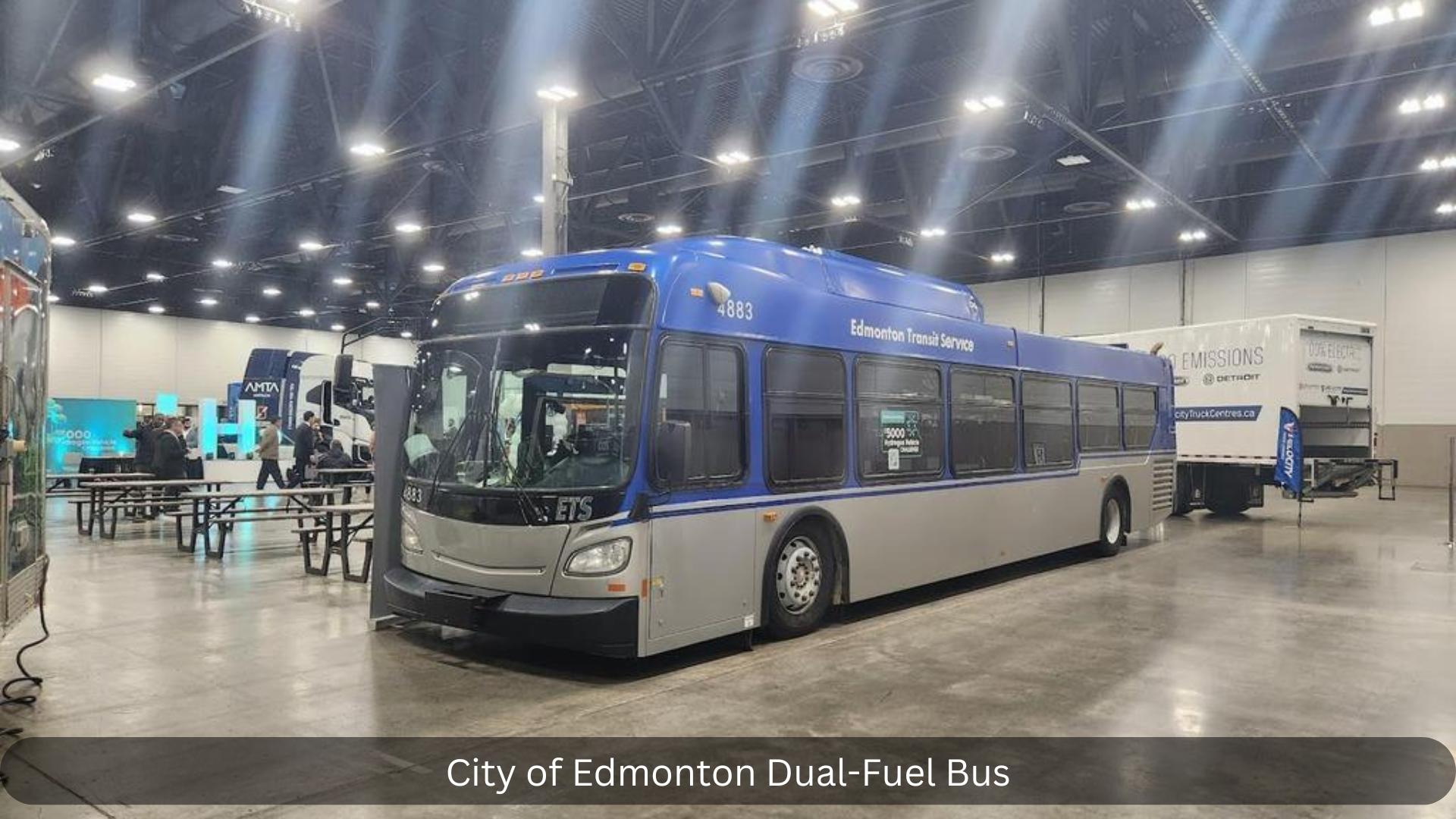

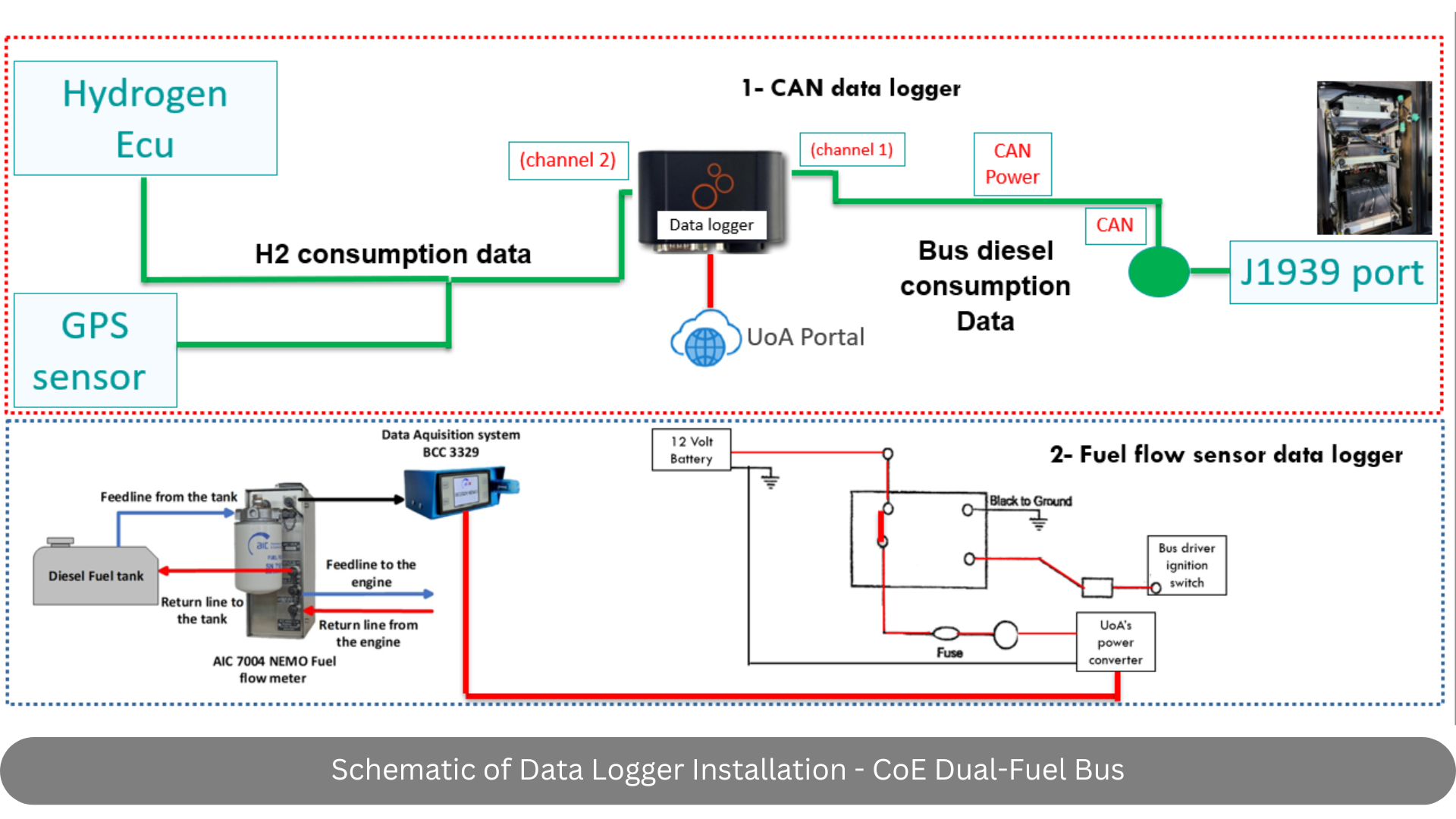

The Alberta Zero Emission Fuel Fleet (AZEFF) project is an initiative led by City of Edmonton to advance sustainable waste management transportation. As part of this project, Energy Mechatronics Lab (EML) is gathering operational data from one dual-fuel bus and two duel-fuel waste and long haul trucks operated by the City of Edmonton, focusing on vehicles employing dual-fuel and fuel cell technologies sourced from various manufacturers.

Data collected from these trucks will span a comprehensive range of parameters, including fuel efficiency, emissions, and operational performance across varying load and environmental conditions. This data will support detailed analyses aimed at understanding the impact of dual-fuel technologies on emissions reduction, energy efficiency, and overall cost-effectiveness in waste collection services. Ultimately, the project seeks to deliver insights on the viability of integrating low-emission technologies in municipal fleets, contributing to cleaner, more efficient urban waste management solutions.

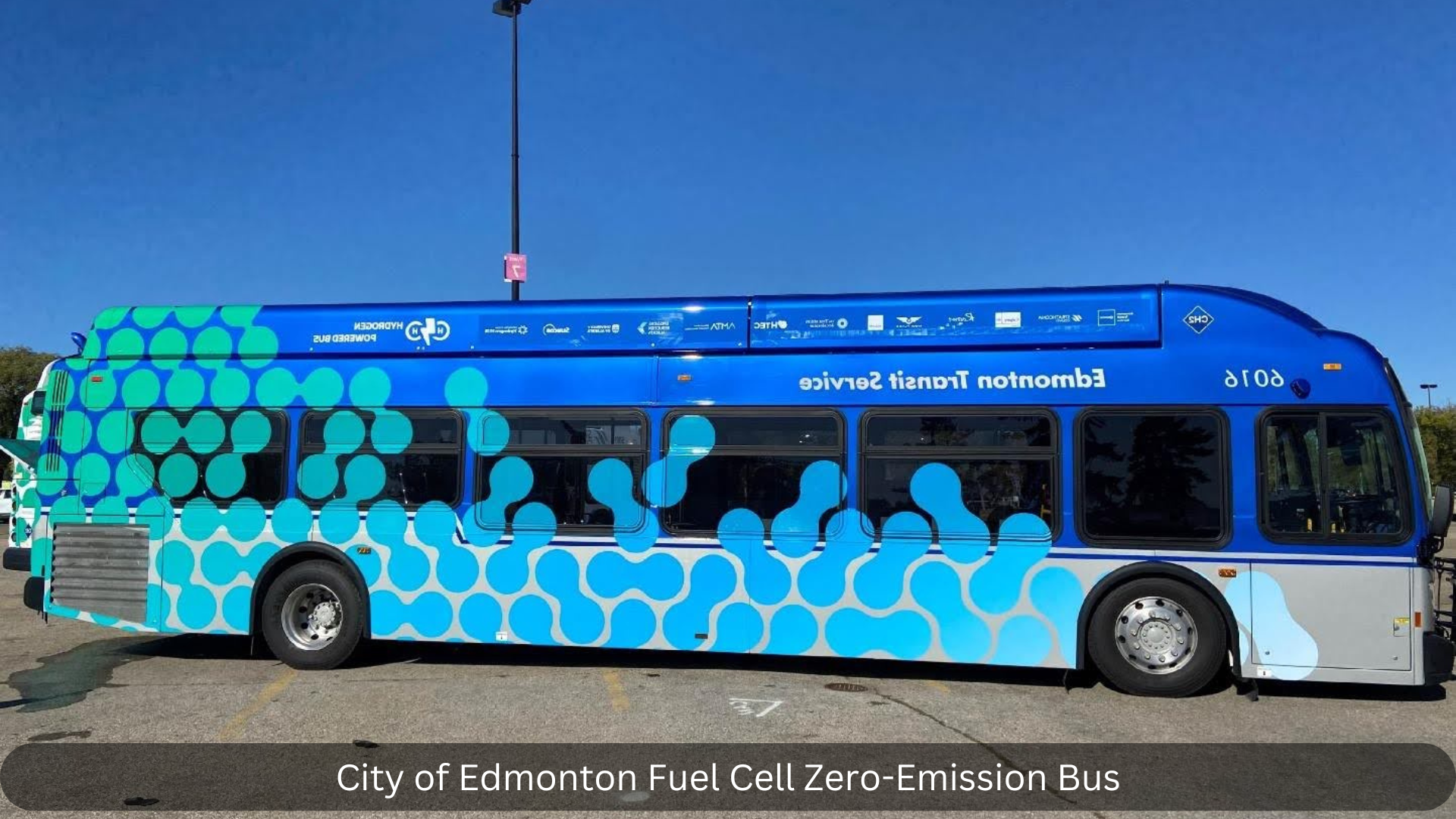

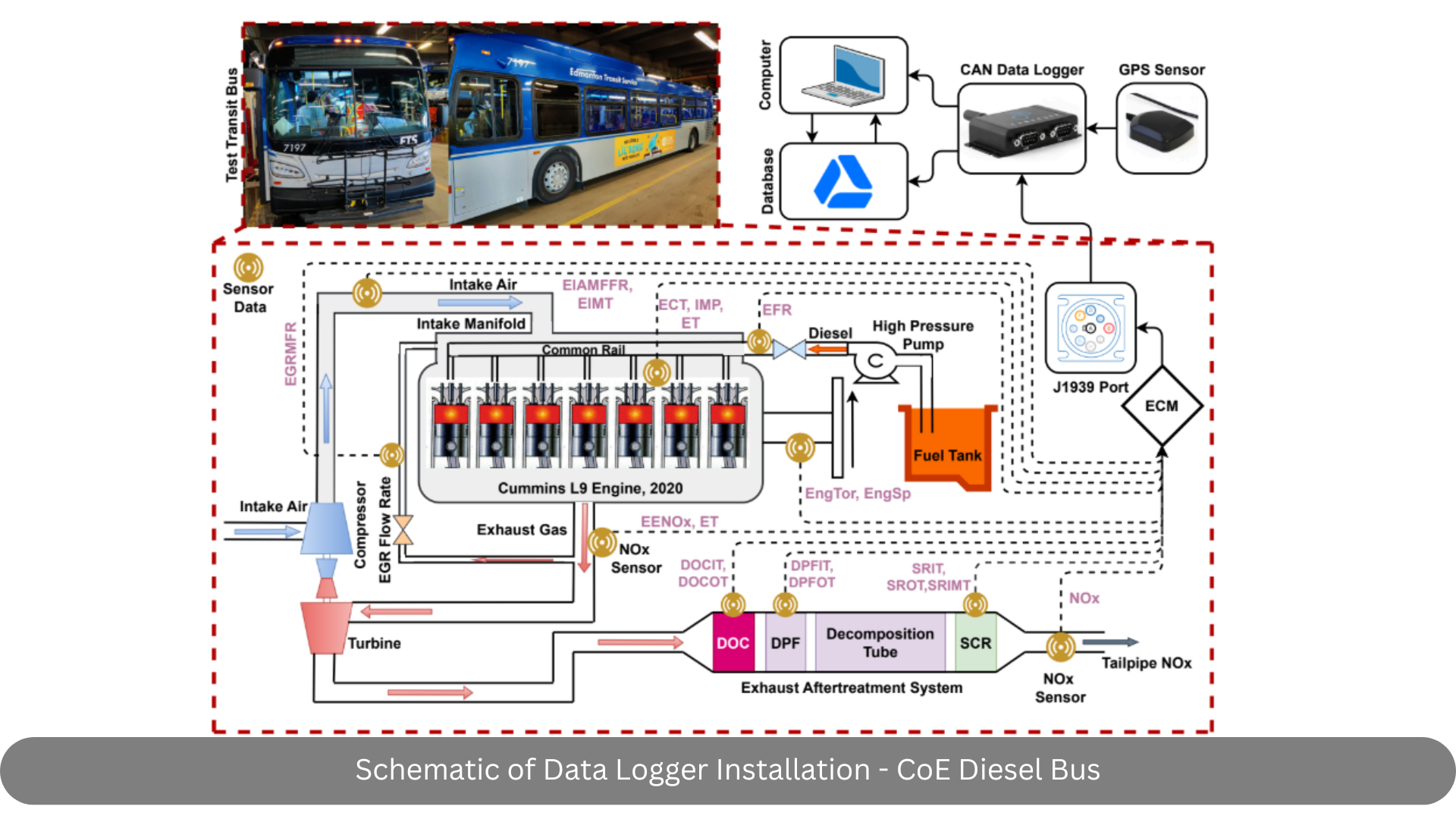

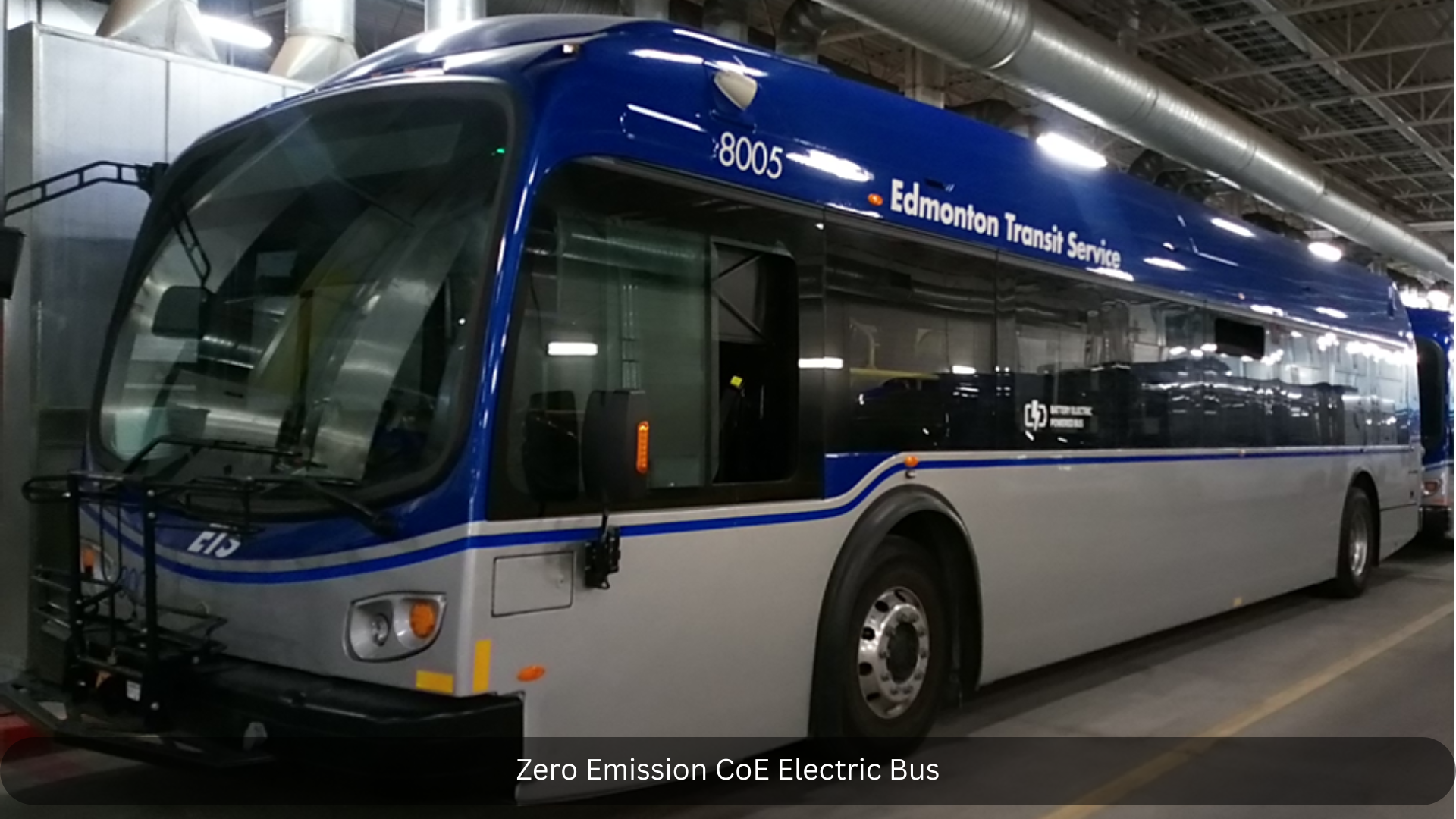

AZEHT (Alberta Zero-Emissions Hydrogen Transit)

The AZEHT (Alberta Zero-Emissions Hydrogen Transit) project is focused on advancing the understanding and performance of diesel, electric, and fuel-cell bus technologies under various operational conditions. In this project, the Energy Mechatronics Lab (EML) has gathered comprehensive data, surpassing 260,000 kilometers, on three bus types: diesel, electric, and fuel-cell, which service routes for both the City of Edmonton and Strathcona County. This data spans five buses from multiple manufacturers, encompassing diverse parameters like fuel efficiency, power output, and environmental impact.

Our analysis leverages these detailed datasets to assess real-world energy consumption, maintenance requirements, and overall reliability. Key insights include understanding the energy demands across different urban and interurban routes and assessing the seasonal variations in performance, especially the impact of colder climates on battery efficiency and fuel cell reliability. This data will inform recommendations for an optimized mixed fleet that aligns with energy and emission reduction goals while providing robust transit options for these regions.

Alberta Zero Emission Truck Electrification Collaboration (AZETEC)

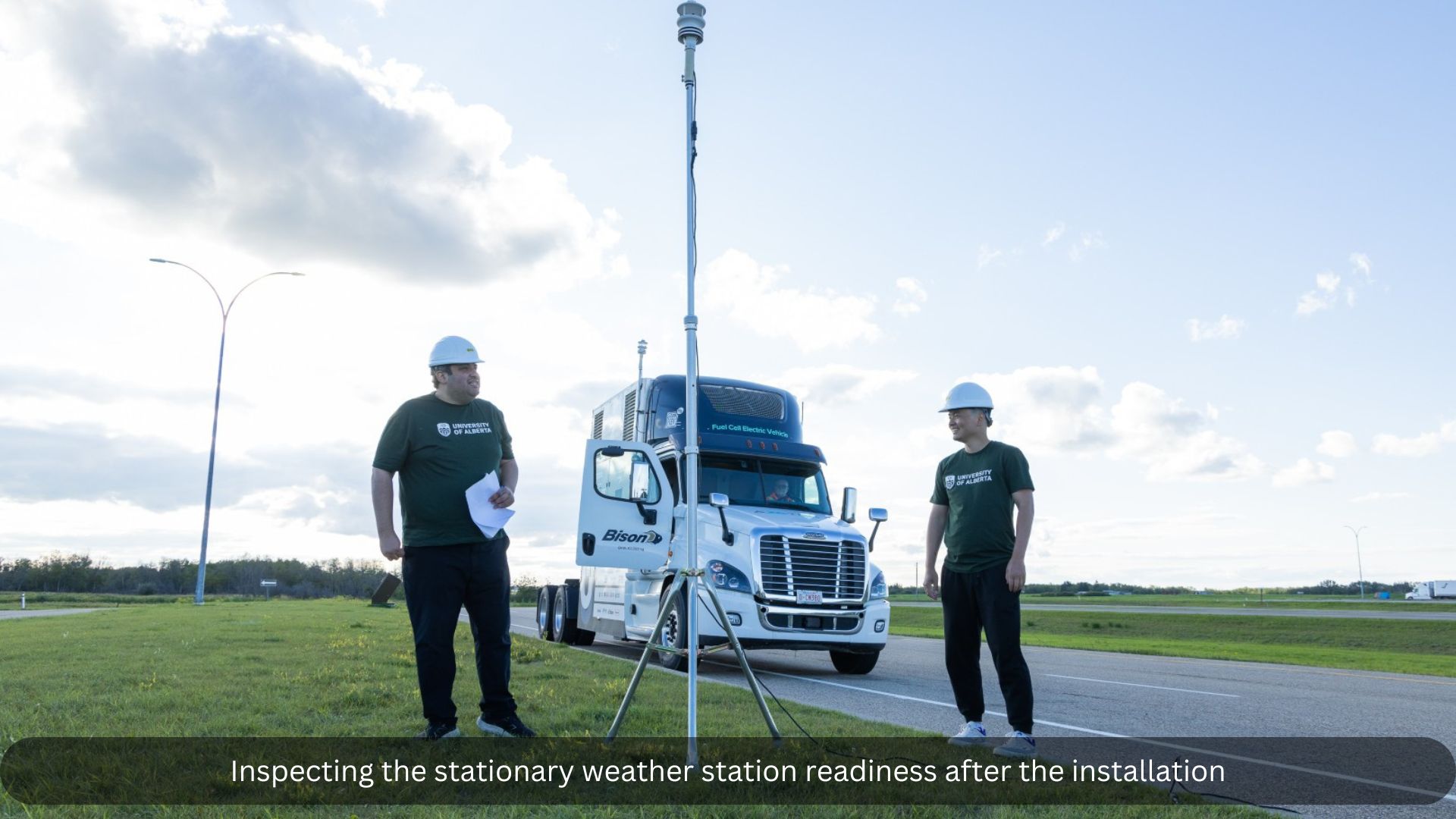

The AZETEC project centers on two 64-ton class 8 trucks powered by PEM fuel cells manufactured by Ballard Power Systems, integrated with a lithium-ion battery pack into a hybrid electric drive designed by Dana. These systems are built on a Freightliner Cascadia Class 8 truck platform.

The Energy Mechatronics Lab (EML) has examined the effects of controlled variables, such as cargo loads, truck velocity, and driving modes (cruising, acceleration, deceleration), as well as uncontrolled variables, including ambient temperature, wind speed, and traffic conditions (acceleration/deceleration frequency), on the trucks’ performance. Additional objectives include investigating the trucks’ maximum driving range, analyzing powertrain efficiency compared to conventional diesel trucks, and evaluating cold-start capability at ambient temperatures ranging from -10℃ to -30℃.

This study will also compare the AZETEC trucks' energy consumption with that of traditional diesel trucks, examining how climate factors (ambient temperature, humidity, wind) impact energy use, as well as cabin climate conditioning capability and its effects on energy efficiency. The trucks' performance will first be evaluated through baseline testing, including cruising and range tests with different cargo loads, followed by a performance evaluation during commercial operation.

Zero Emission Truck Testbed (ZETT)

In the ZETT project, the performance of three fuel cell Class 8 trucks—manufactured by Nikola, Hyzon, and the AZETEC prototype—will be assessed by the Energy Mechatronics Lab (EML). This includes testing the two trucks on various routes within Alberta. Additionally, the performance of a battery-electric Volvo truck will be evaluated during its commercial operation between British Columbia in Canada and Washington State in the US. The three fuel cell trucks will undergo baseline testing against a conventional diesel truck to compare the technologies. This testing will include a series of road evaluations, such as cruising tests, range assessments, and driving on high-slope roads, among other scenarios.

The study’s objectives are to analyze the impact of factors such as cargo loads, truck velocity, driving modes (cruising, acceleration, deceleration), ambient temperature, wind speed, and traffic conditions (acceleration/deceleration frequency) on the trucks’ performance. Additional goals include investigating the vehicles’ maximum driving range and analyzing powertrain efficiency in comparison to conventional diesel trucks. The study will also assess energy consumption relative to traditional diesel trucks, examining the influence of climate factors (ambient temperature, humidity, and wind) on energy use, as well as the effects of cabin climate conditioning on energy efficiency.

Hydrogen-Diesel Truck Testing

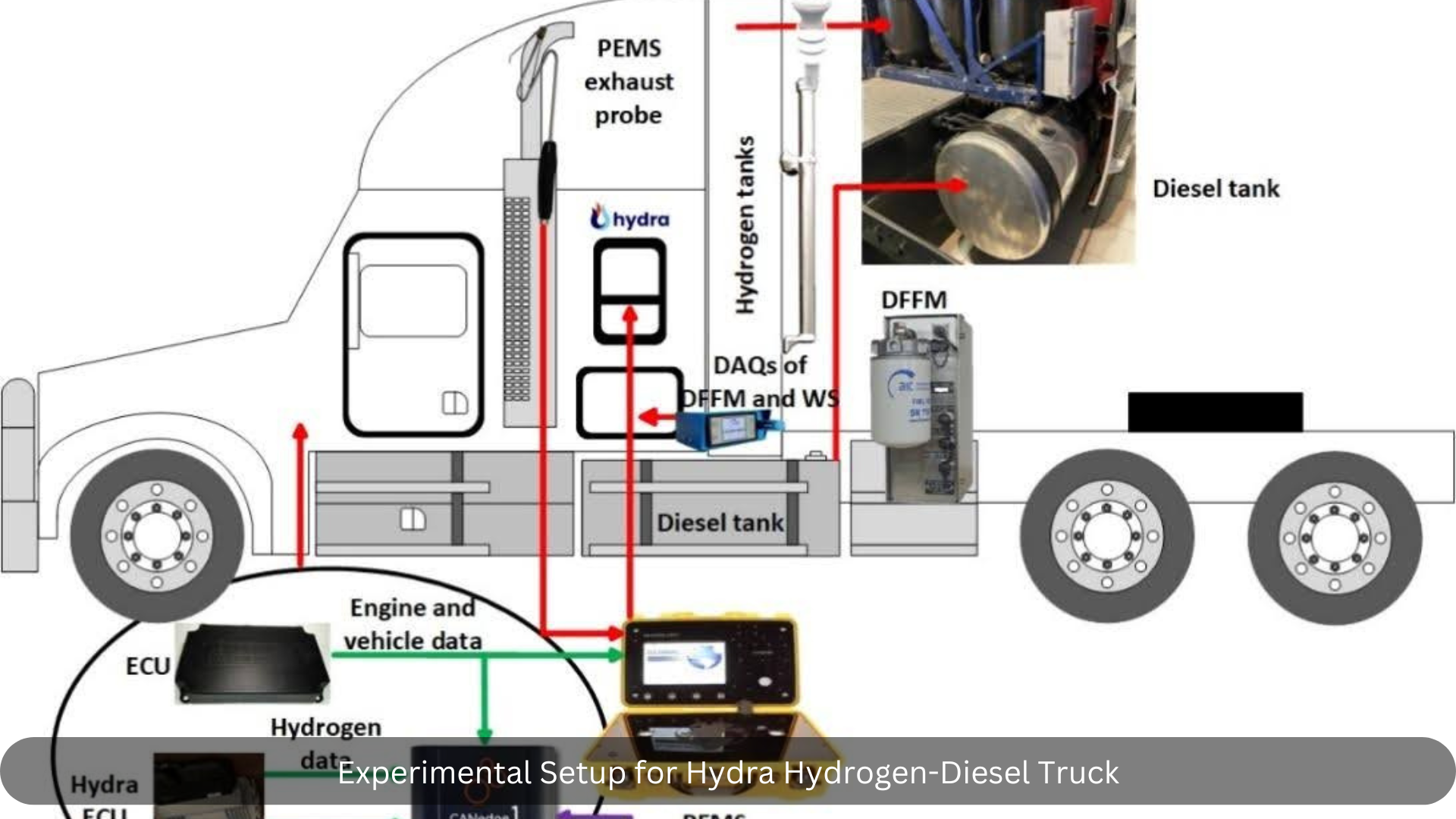

The Energy Mechatronics Lab (EML) has instrumented and tested a hydrogen-diesel dual fuel heavy duty truck that was retrofitted by Hydra Energy Inc. The truck was retrofitted with a hydrogen conversion kit to supply hydrogen to a 15.6-liter Detroit diesel engine, enabling operation in a dual-fuel mode. The objectives of this project included collecting real-time truck operational data (vehicle and powertrain/engine parameters, exhaust emissions, fuel consumption, and environmental conditions such as temperature and wind speed). In this project, the EML team analyzed the fuel conversion efficiency of the truck under hydrogen-diesel operation compared to diesel-only operation, determine tailpipe emissions (PM, CO, NOx, CO₂, and uHC) as a function of engine speed, load, and hydrogen substitution, compare engine-out NOx emissions in diesel-only vs. hydrogen dual-fuel modes, measure CO₂ emissions reduction through hydrogen use, and assess the effects of truck weight, wind speed, and ambient conditions on fuel consumption and emissions. The study also investigated hydrogen and diesel consumption rates during idling, cruising, and acceleration.

The truck was equipped with a data logger to capture vehicle data, a portable emissions measurement system to record exhaust emissions, a diesel fuel flow meter for fuel consumption, and a weather station to record ambient conditions. During the data collection campaign, we successfully gathered approximately 7,500 km of ECU and hydrogen consumption data, 6,800 km of NOx emissions data, 4,500 km of diesel consumption and weather station data, and 3,500 km of general emissions data.

Analysis results indicated that using hydrogen alongside diesel fuel led to reductions in CO₂ and PM emissions, though it also resulted in increased NOx and CO emissions. Notably, the truck's thermal efficiency remained nearly the same in both diesel-only and hydrogen-diesel operations.

Cooperative Truck Platooning System (CTPS)

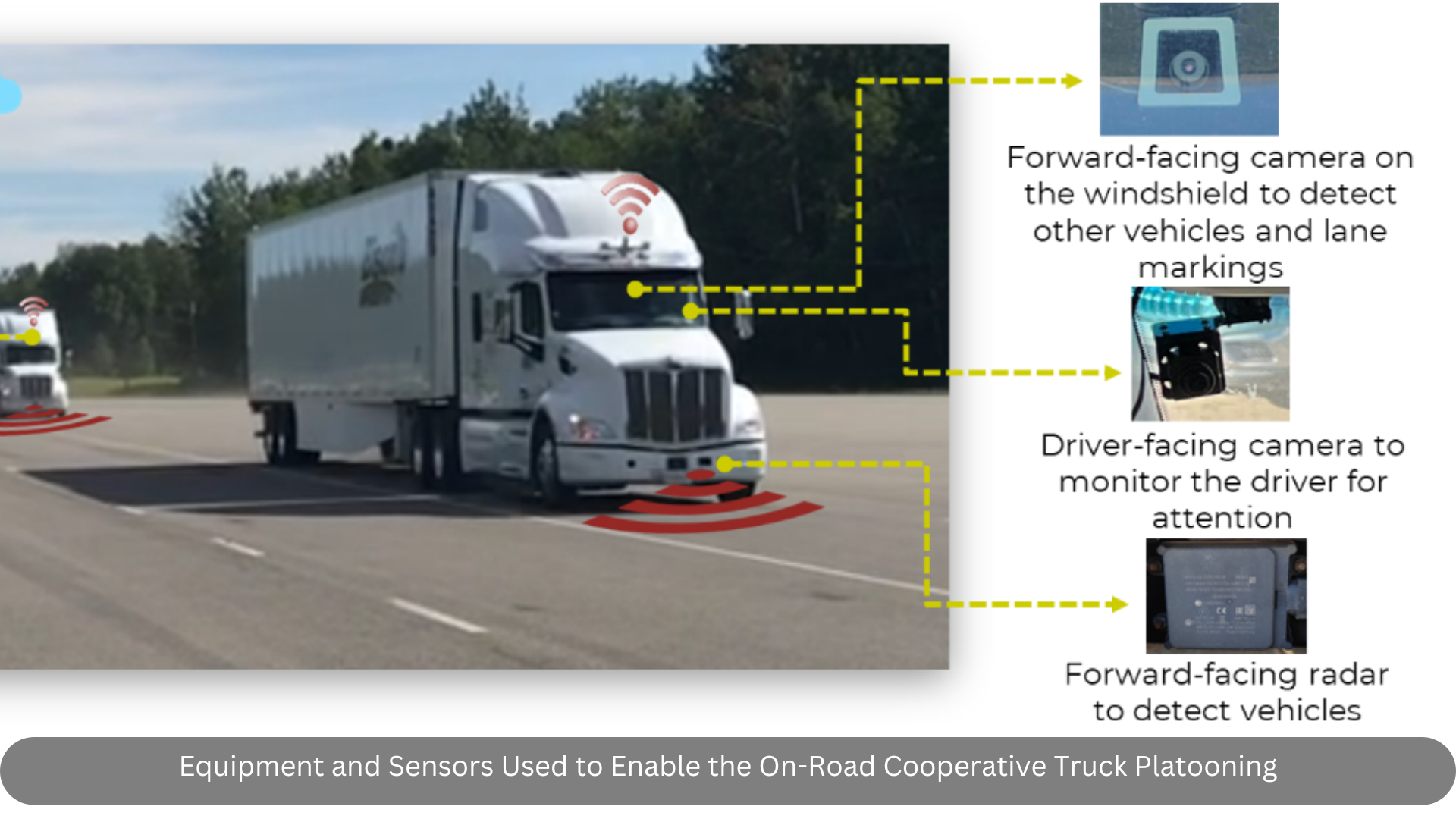

The Energy Mechatronics Lab (EML) designed an innovative data acquisition system (DAQ) and instrumented two Peterbilt 579 trucks as part of the CTPS trials sponsored by Transport Canada. The EML team collected the data from several units including Cummins engine and exhaust aftertreatment systems, truck platonning system, weather station, diesel fuel flow meter, cameras, in-cabin temperature, CO2, humidity sensors along with several other systems. The data was used to analyze performance of the lead and follower trucks during CTPS trials.

In the CTPS trial, the platoon consisted of two SAE Level 2 Class-8 trucks equipped with the cooperative truck platooning system. This system included a global positioning system (GPS), vehicle-to-vehicle (V2V) communication, cameras, radars, and other sensors. The time gaps of the platooning trips on Alberta’s public highway were set to 3-5 seconds, which filled the gap in implementing on-road truck platooning for commercial operation at large separation distances.

This CTPS trial included 41 incident-free commercial trips, covering a total distance of 22,855 km. This study provides real-world data to identify limitations and needed areas for improvement in adapting cooperative truck platooning technology to commercial operations on public roads.

EMSO (Energy Management and Sustainable Operations)

The Energy Mechatronics Lab (EML) in collaboration with the Office of Energy Management and Sustainable Operations (EMSO) initiative and Transportation Services of the University of Alberta, conducted a project for monitoring and optimization of the university fleet vehicles.

The university fleet includes over 170 vehicles, includes sedans, SUVs, pickups, vans, and buses, with various powertrain options such as internal combustion engines, hybrid electric, plug-in hybrid, and battery electric vehicles.

Phase 1 of the EMSO project focused on establishing a network of connected vehicles, collecting operational data from vehicles, and measuring energy consumption of the university's fleet. The project established a connected fleet equipped with data collection devices, enabling vehicles to transmit on-board diagnostics (OBD) and GPS data wirelessly and via cellular networks to a central server. This connectivity supports the intelligent management of fleet operations. Fleet vehicles serving various purposes and applications provided real-time OBD and GPS data, as well as fuel and energy consumption data, during routine activities under real driving. It facilitated the development of representative drive cycles, machine learning models for fuel consumption estimation, and insights into energy consumption patterns across different powertrain systems. Comprehensive testing across a wide range of ambient temperatures further enabled the comparative analysis of energy consumption and CO2 emissions, particularly highlighting the performance of different powertrain systems in cold climates.

Outcomes from the project allow fleet managers to monitor fleet energy consumption and CO2 emissions, provide better insights into the strengths and limitations of each powertrain option considering climate conditions and empowering them to manage the fleet more effectively.

EMSO 2 (Energy Management and Sustainable Operations)

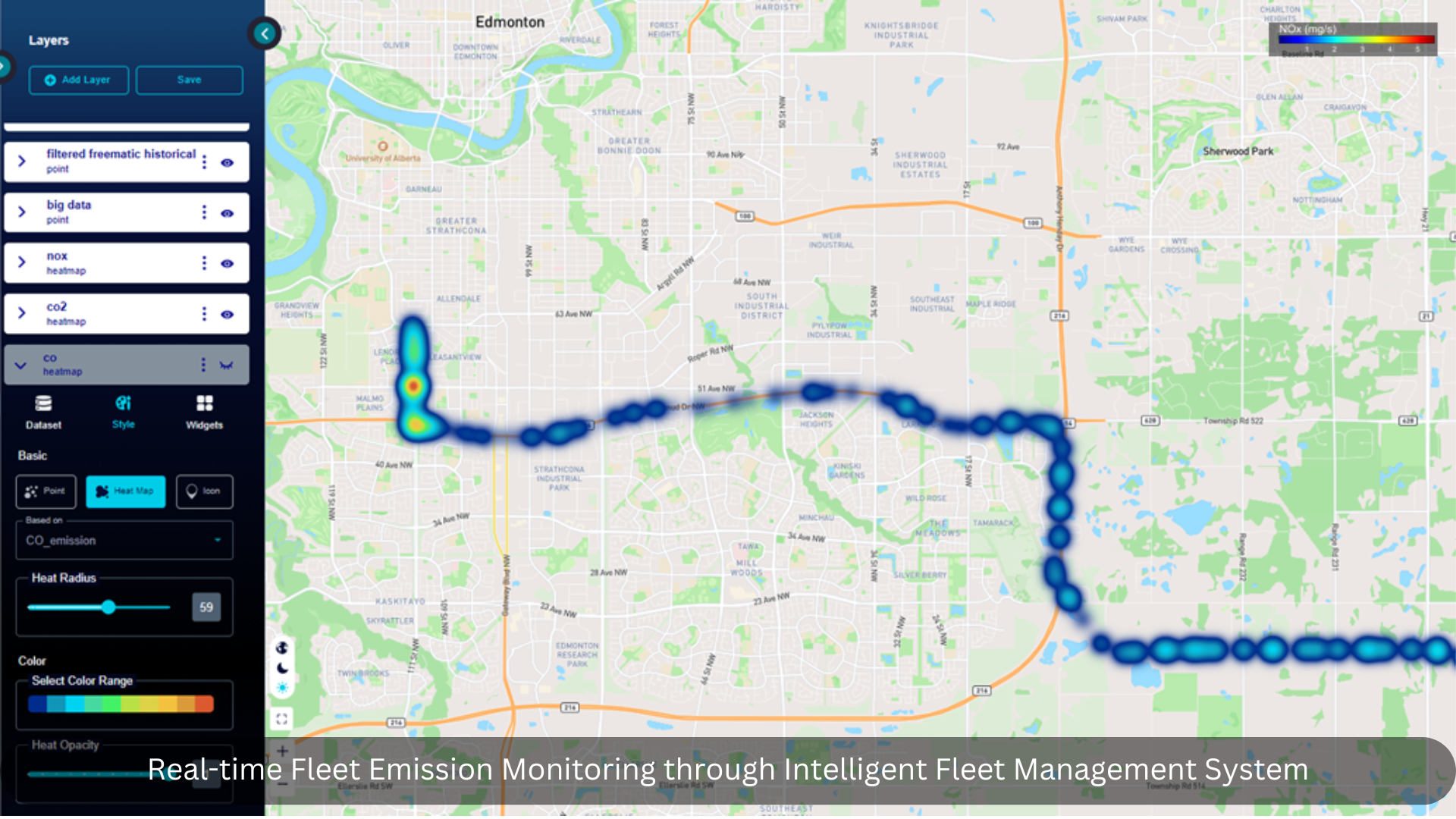

In phase 2 of the project, denoted as EMSO 2, the EML team focused on developing an advanced intelligent fleet management system for monitoring and optimizing fleet emissions and energy consumption. Representative vehicles, including various powertrain options—internal combustion, hybrid electric, plug-in hybrid, and battery electric—are tested under real-world driving conditions. These tests collect comprehensive energy and emissions data, including CO2, CO, unburned hydrocarbons (UHC), NOx, and particulate matter (PM). The testing is conducted across a wide range of ambient temperatures, including extreme cold conditions as low as -30°C.

The collected data is used to develop emission estimation models utilizing machine learning techniques, based on on-board diagnostics (OBD) data. The intelligent fleet management system, which collects OBD data from fleet vehicles using cellular IoT modules, incorporates an innovative data management framework and specialized software developed in collaboration with ReWheel Technology Inc. By integrating machine learning-based emission estimation models, the software enables real-time monitoring of vehicular emissions while aligning with standard fleet management practices. The system is designed to be compatible with various powertrain options, making it suitable for mixed-powertrain fleets.

Leveraging data-driven models and outcomes from EMSO 1—such as representative drive cycles—the project aims to optimize fleet operations. This includes vehicle assignment strategies and fleet renewal planning to minimize emissions and energy consumption, ultimately achieving more sustainable and efficient fleet operation.