HVAC Projects

Building Energy Efficiency

Building energy efficiency is a crucial aspect of modern sustainable design, aimed at reducing energy consumption while maintaining indoor comfort and air quality. Heating, ventilation, and air conditioning (HVAC) systems play a central role in optimizing energy use, especially in enclosed spaces where air circulation impacts both thermal comfort and infection risk. With the rise of intelligent building control systems, new strategies are being developed to balance energy efficiency with occupant health and comfort. These advancements integrate dynamic models, sensor networks, and machine learning techniques to optimize HVAC operation based on real-time environmental and occupancy data.

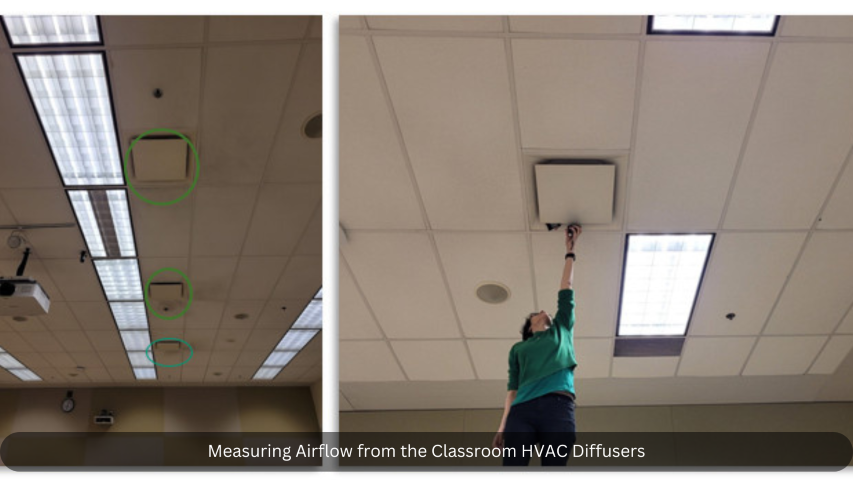

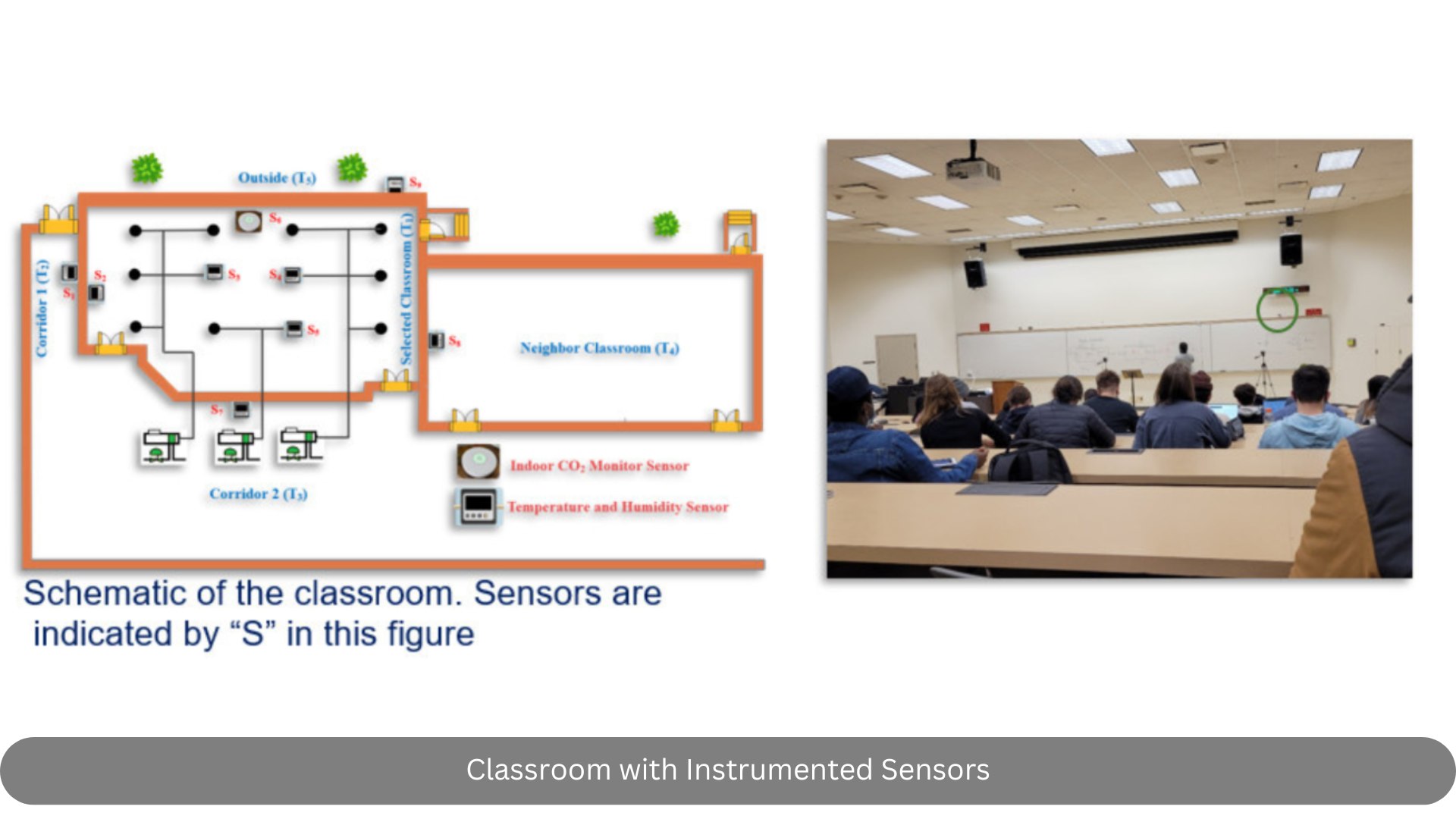

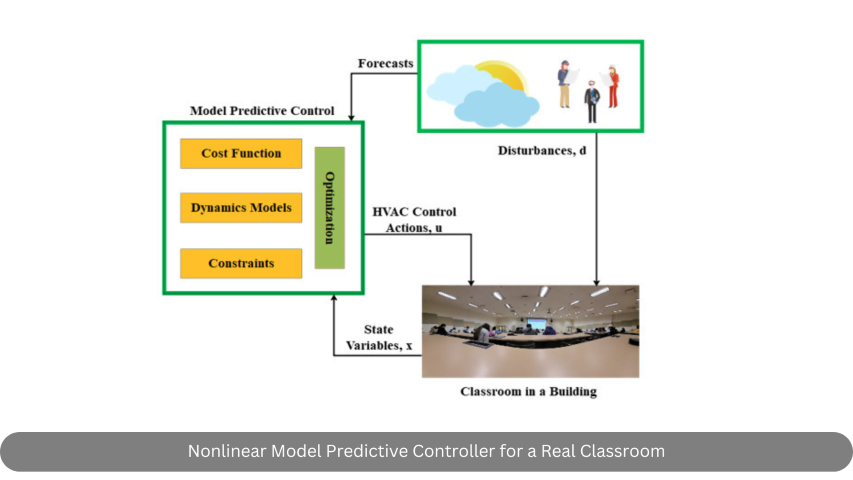

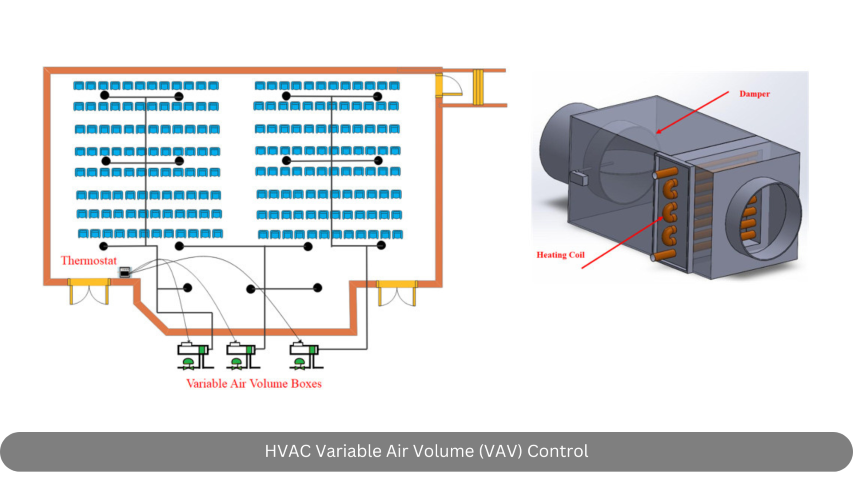

This project focused on designing an intelligent HVAC control system that minimizes energy consumption while maintaining indoor air quality. A Model Predictive Control (MPC) approach is implemented to assess the tradeoff between ventilation rates and energy usage in university buildings. By utilizing dynamic models of heat transfer and air circulation, the system predicts future environmental conditions and adjusts airflow rates and supply air temperatures accordingly. Experimental validation conducted in a university classroom demonstrated a 54.8% reduction in daily energy consumption compared to the existing baseline controller while effectively mitigating airborne infection risks. The study highlights the potential for smart control strategies to significantly enhance building energy efficiency, providing a scalable solution for optimizing HVAC systems in educational and commercial settings.

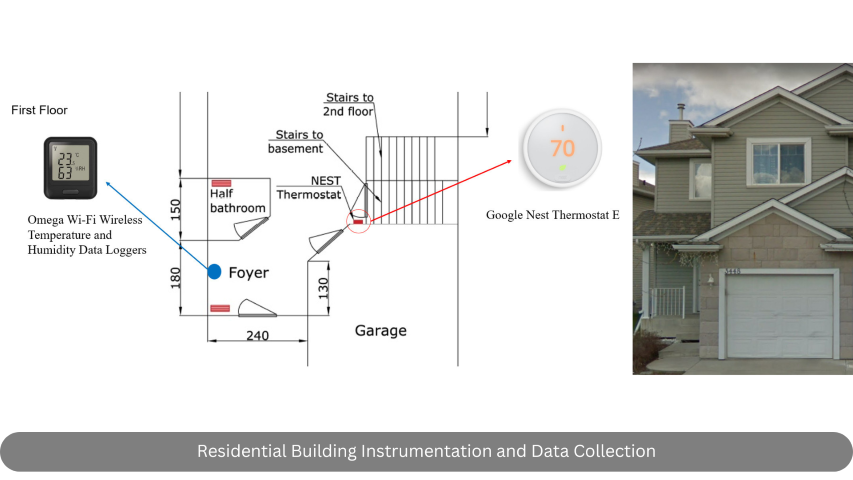

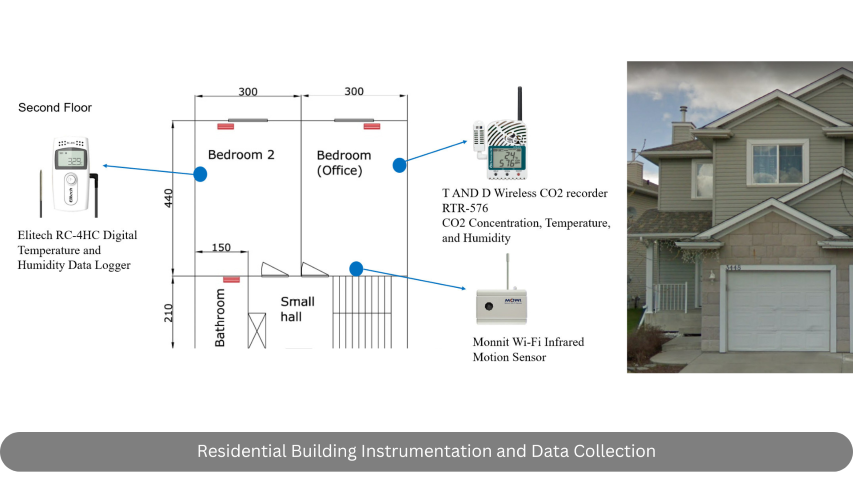

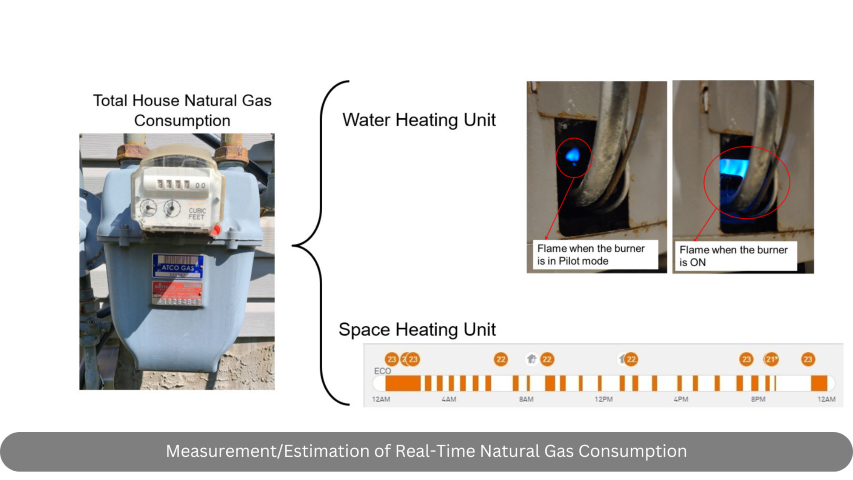

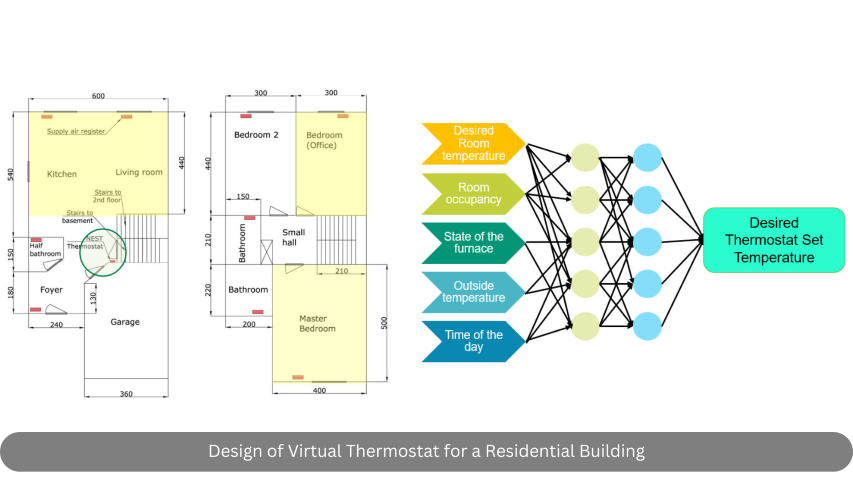

In parallel, an occupancy-based control system for residential heating is being explored to further improve energy efficiency in homes. By employing sensor fusion techniques, real-time occupancy data is used to adjust heating schedules dynamically, reducing unnecessary energy consumption. A machine learning model, incorporating K-nearest neighbors (KNN) and other algorithms, was developed to predict occupancy with high accuracy. Coupled with a 3D energy model of a residential building, the system demonstrated energy savings ranging from 9.5% to 30.7%, leading to a reduction in heating costs of up to 30%. These findings emphasize the importance of integrating occupancy data into building management systems, paving the way for more adaptive and efficient energy solutions in both residential and commercial buildings.

Indoor Air Quality

Indoor air quality is a global concern, impacting both health and comfort. Exposure to indoor air pollution can lead to various health issues, as HVAC systems circulate airborne contaminants like viruses, bacteria, and mold throughout buildings.

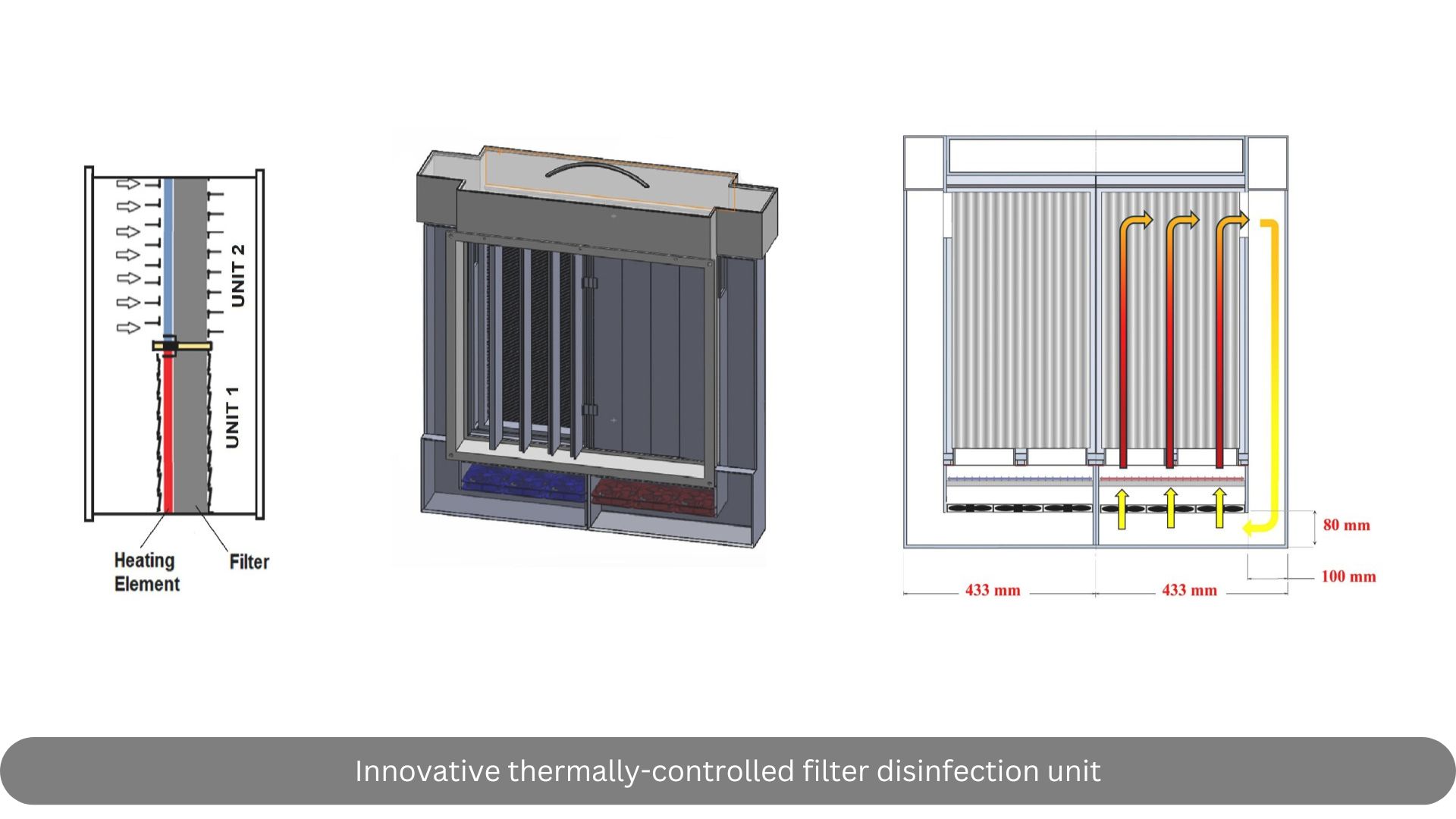

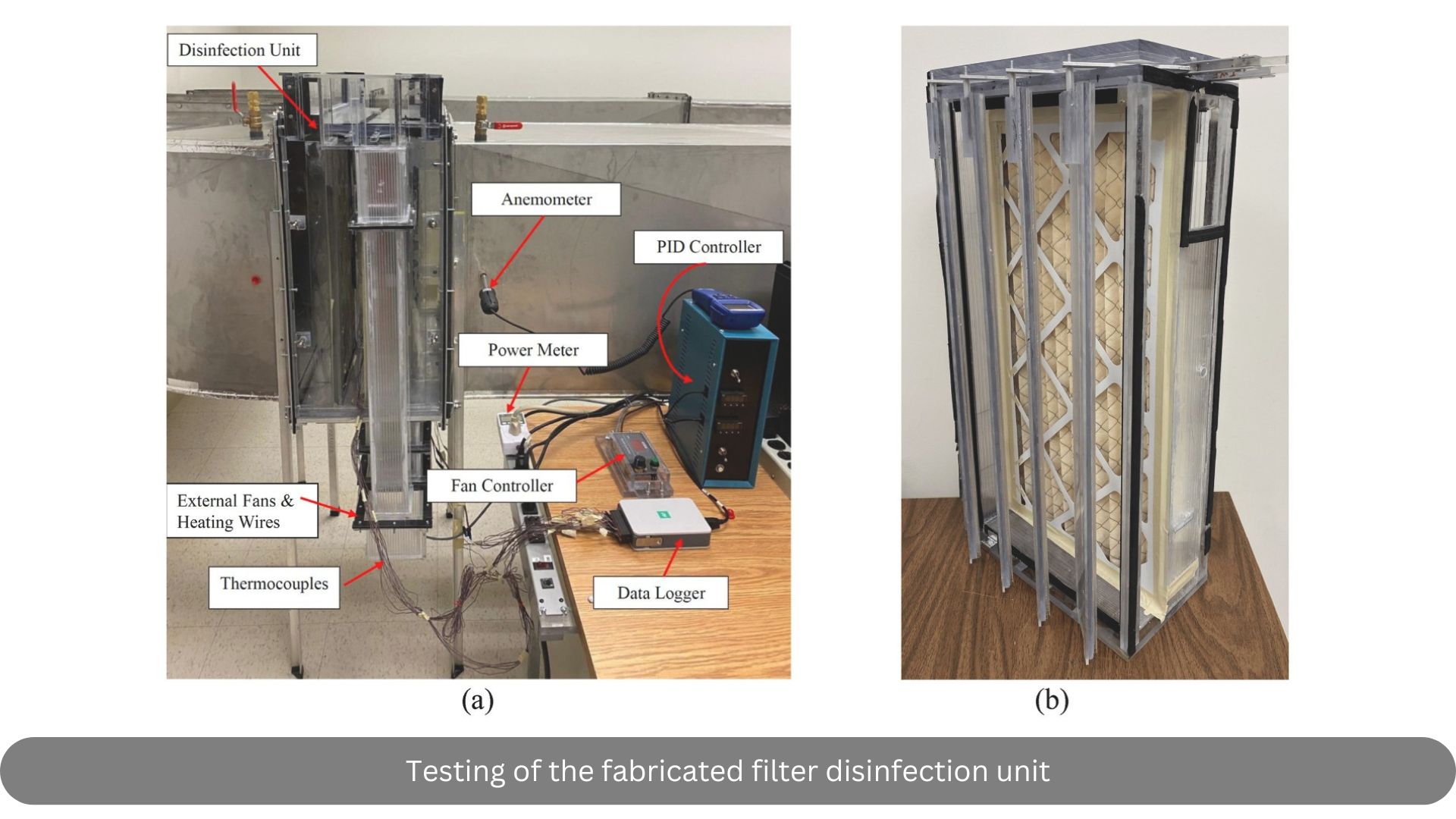

The EML team in collaboration with Professor Nouri's group received funding from NSERC Alliance, in partnership with EngineeredAir Inc to develop an innovative technology to entrap and destroy pathogens suspended in the air in ventilated buildings.

Several infectious germs, such as coronavirus and influenza, may travel in the Heating, Ventilation, and Air Conditioning (HVAC) system while encapsulated in minute droplets. The HVAC ducts can serve as conduits for the circulation and spread of infectious diseases in the building. Further, all HVAC filters entrap and accumulate microbes to the extent that depends on the filter specification and filter replacement frequency. Accumulation of microbes in the filter can turn the filter into a breeding ground for fungi and bacteria, making the filter a biologically hazardous object. Hence, the filter disposal may become hazardous unless a safe disposal protocol is followed to minimize the risks. Also, any change or disturbance in the airflow may release some of the microbes into the environment. In the past, Ultraviolet (UV) light has been employed to reduce biological contaminants in the air. However, the installation of existing technology in the HVAC system is not easily possible and is limited by the HVAC system's design. For more conventional HVAC systems such as duct-based systems, installing such units is often costly and labour-intensive. Hence, such units are seldom used in HVAC systems outside the healthcare buildings.

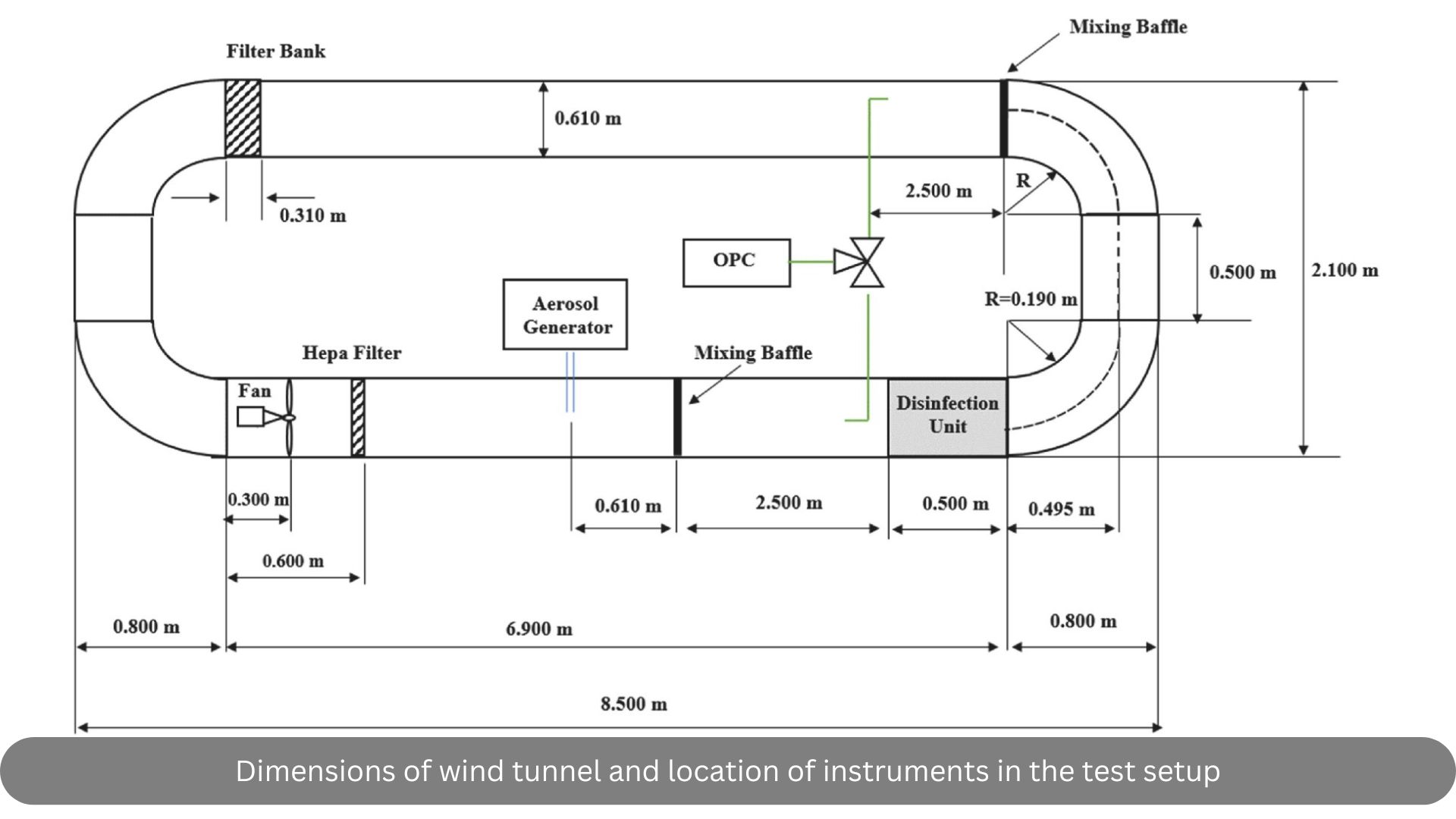

This project developed a compact and economical device that works based on entrapping microbes by the HVAC filters and inactivating them by heating. The aim is to conduct proof of concept tests, build the prototype, develop efficient, optimal and cost-effective units, and advance guidelines for the geometries/configurations, materials, operations, and specifications. All ventilated buildings such as hospitals/clinics, high-rises, and care facilities can benefit from this technology. The technology can eliminate the microbes effectively and can easily be installed in existing and new HVAC systems. Calculations indicate more efficient microbial inactivation than existing UV technologies at a fraction of the cost. The technology is expected to be commercialized by the industrial partner.

HVAC Performance in Class 8 Sleeper Trucks

The total energy consumption of class 8 sleeper trucks is significantly affected by Auxiliary Unit (AU) systems. According to the U.S. Federal Motor Carrier Safety Administration (FMCSA), AU power demand increases during extreme weather. In sleeper trucks with cabin volumes exceeding 8 cubic meters and operating over 10 hours per day, a substantial portion of this power is used by the HVAC system. The HVAC system regulates cabin temperature and ensures windshield defrosting and demisting. In conventional sleeper trucks, the required heating energy is derived from the heat losses of the Internal Combustion Engine (ICE), with only the power required to run the AC compressor impacting fuel consumption. However, in hybrid/electrified sleeper trucks, whether featuring a downsized ICE or operating solely on a battery electric system, additional energy is consumed not only by the AC compressor but also by an electrical heater. Accurately estimating the total HVAC auxiliary load required during a trip remains a significant challenge in the design of electrified class 8 sleeper trucks.

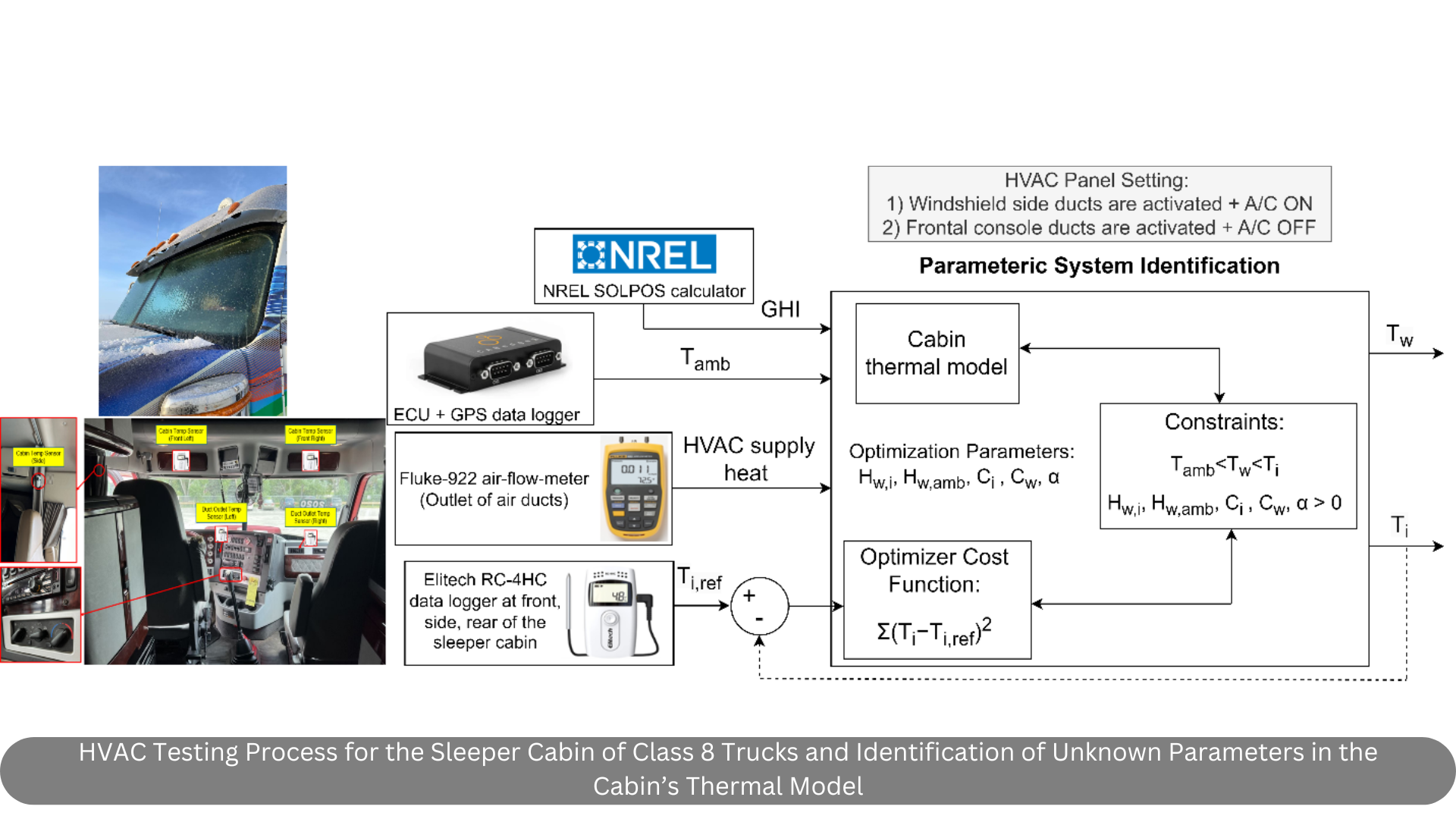

To assess HVAC auxiliary load in class 8 sleeper trucks, a series of experimental tests were conducted under extreme weather conditions. High-precision thermocouples were strategically placed throughout the cabin, including seating areas, air vents, entry points, and ceiling zones. A data logger continuously captured temperature variations at high temporal resolution, recording transient thermal fluctuations caused by HVAC operation. Additionally, high-precision OBD-II data loggers collected all Engine Control Unit (ECU) data during both stationary and dynamic test modes. The ECU data loggers were equipped with GPS sensors to capture location data of the tested vehicles, as well as road grade information.

The primary objectives of this analysis were:

- Estimate the total HVAC heating load required to maintain stable and comfortable in-cabin temperatures.

- Determine the duration of AC compressor on/off cycles to estimate the total auxiliary energy consumed by the air-conditioning system.

- Analyze air humidity levels at various cabin locations to establish a relationship between windshield defrosting system activation and the likelihood of mist formation.

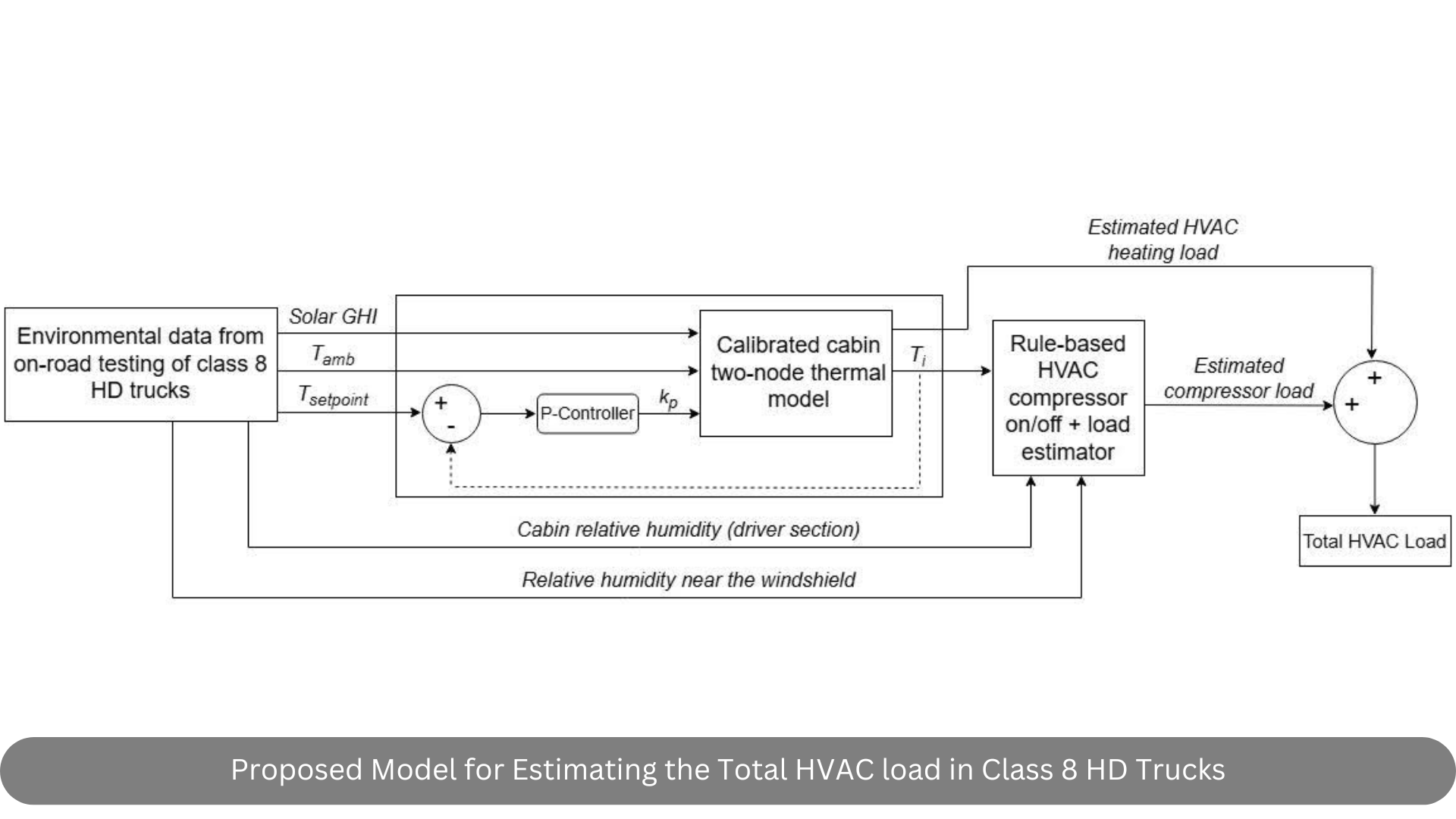

Based on the data collected from the experimental tests, multi-node mathematical models were developed to estimate the HVAC heating load and AC compressor load for class 8 sleeper truck. After validation, this model can predict the total HVAC auxiliary load using parameters such as cabin set-point temperature, ambient temperature, solar global horizontal irradiation (GHI), and cabin relative humidity near the windshield. A rule-based HVAC compressor on/off estimator model was developed to simulate the actual behavior of the AC compressor.

Using the experimentally validated cabin thermal model and AC compressor load estimator, the total HVAC auxiliary load can be estimated across different ambient temperatures and driving conditions. This approach enables accurate estimation of the HVAC auxiliary load in electrified class 8 sleeper trucks determining the amount of electrical energy required from the battery to maintain cabin temperature or defrost the misted windshield.

HVAC Performance in City Transit Buses

The total energy consumption of city transit buses is also significantly affected by HVAC auxiliary systems, particularly in extreme weather conditions. In city buses, HVAC power demand is influenced by external climate conditions, passenger density, and frequent door openings. Unlike sleeper trucks, transit buses experience continuous passenger movement, which leads to dynamic thermal fluctuations within the cabin.

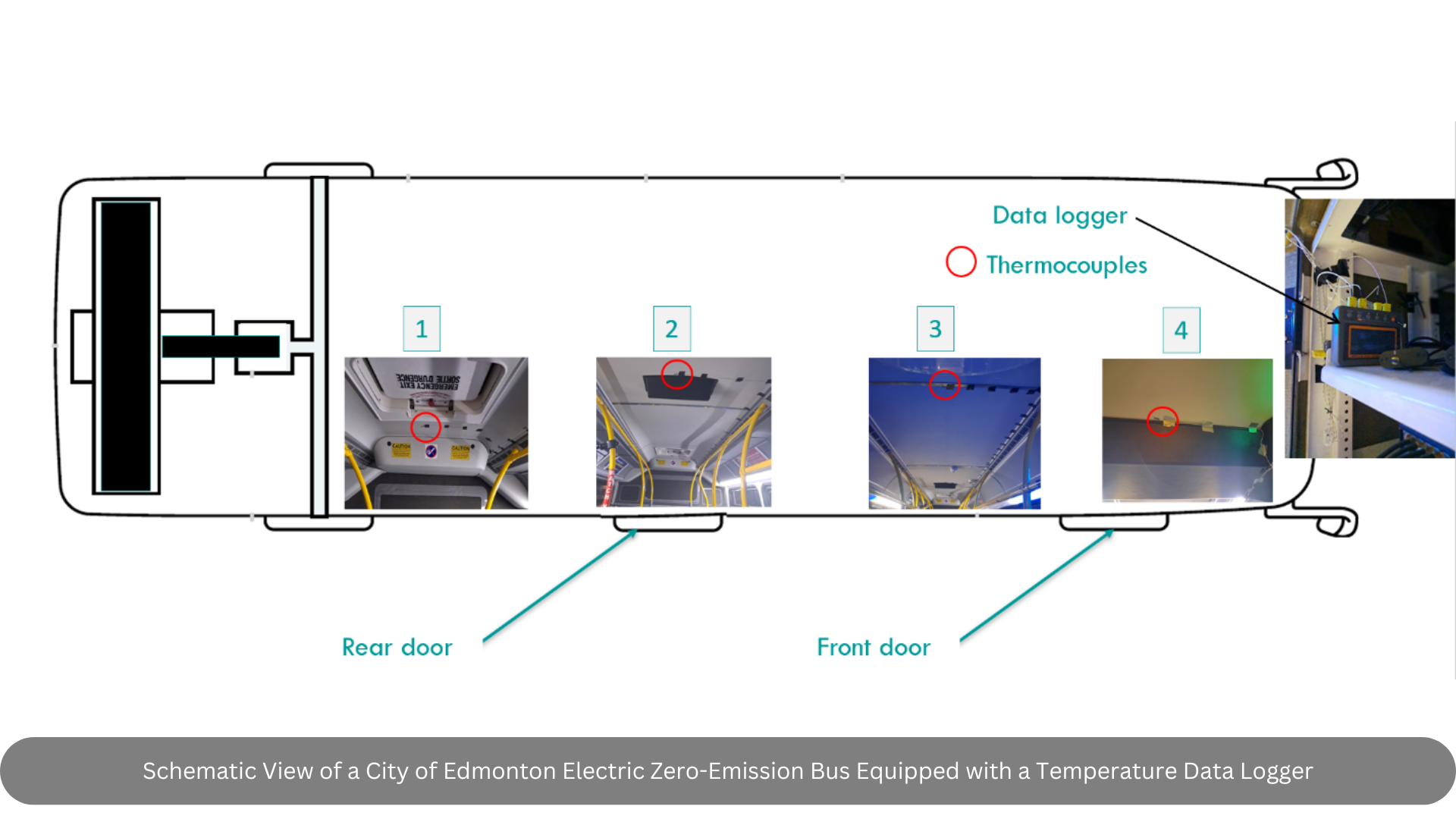

To evaluate HVAC performance in city transit buses, experimental tests were conducted under extreme weather conditions. Similar to the sleeper truck tests, high-precision thermocouples were installed throughout the cabin, including seating areas, air vents, entry points, and ceiling zones. A data logger captured temperature variations at high temporal resolution, while high-precision OBD-II data loggers recorded ECU data, including GPS location and road grade information.

The primary objectives of this analysis were:

- Identify key factors influencing temperature fluctuations, including external climate conditions, passenger density, and door operation cycles.

- Determine optimal seating locations that provide enhanced thermal comfort under varying HVAC performance levels.