Fuel Cell Projects

SOFC-NSERC Alliance

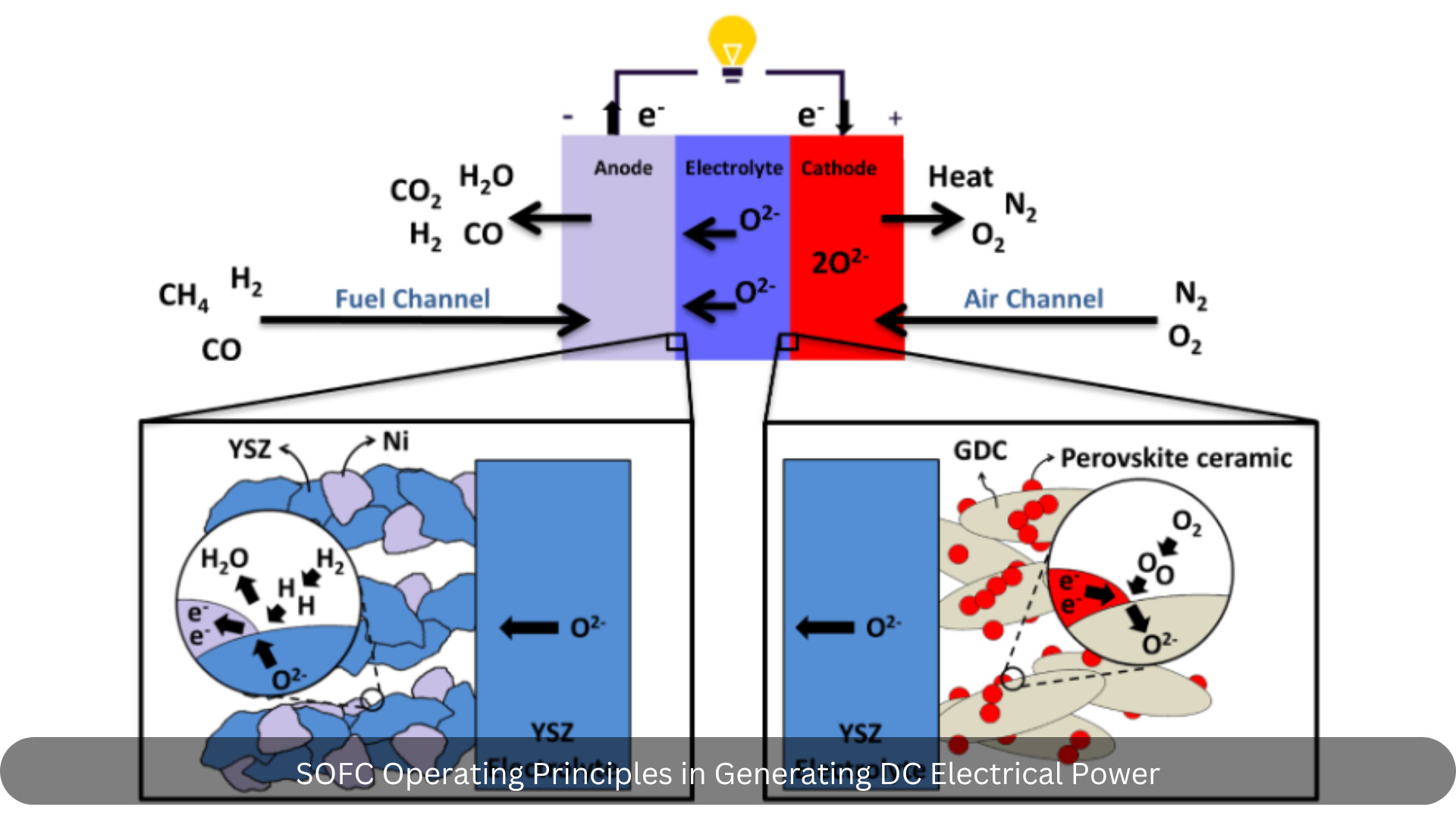

A SOFC (Solid Oxide Fuel Cell) is an electrochemical conversion system that produces power by reacting fuel and oxidant gases at temperatures ranging from 500 to 800 °C. The SOFC advantages are its high efficiency, ability to accommodate various fuel gases, operation at high temperatures (which allows for the utilization of high-quality heat by-products for cogeneration), and absence of precious metals.

The Energy Mechatronics Lab (EML) in partnership with Cummins Inc aim to develop an SOFC stack that meets industry durability criteria while operating under high efficiency under both stationary and transient conditions. To accomplish this, an integrated approach of cell diagnosis and control that is suitable for real-time implementation on fuel cell stacks is proposed. A combination of SOFC stack experimental testing, physical-based modeling combined with data-driven methods, model-based diagnostics, machine learning predictive control, and power electronics design are implemented to diagnose and control individual cells in an SOFC stack using custom power electronics.

Alberta Innovates (SOFC CHP)

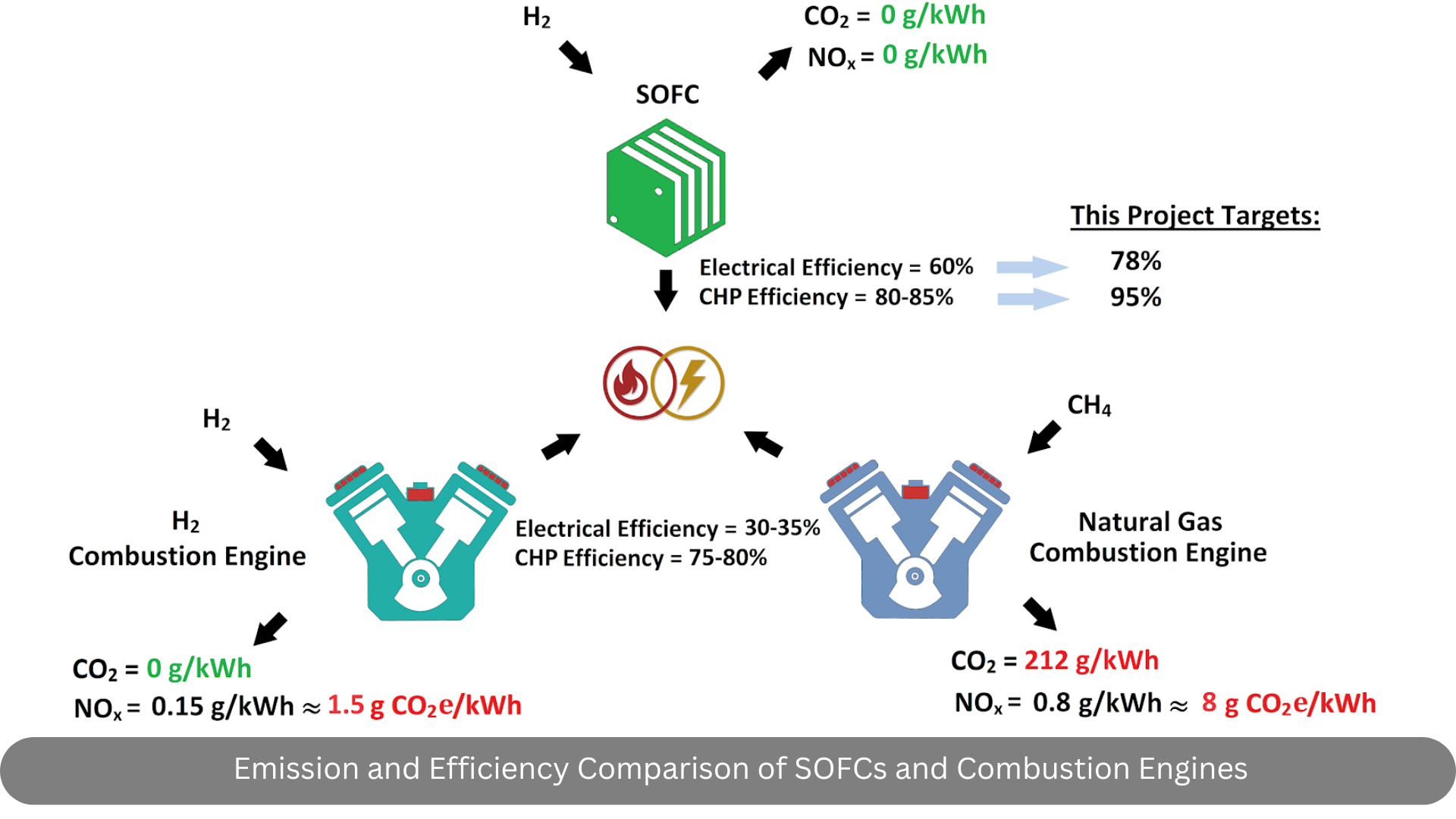

Fuel cells are devices that directly convert fuel energy into electricity. Hydrogen-powered fuel cells, not only produce zero emissions but also offer higher efficiency than traditional combustion technologies. Among various types of fuel cells, solid oxide fuel cells (SOFC) have a high operating temperature, which enhances fuel cells’ electrical efficiency to more than 60%, eliminates the need for costly catalysts, and allows the adaptability to various of fuel. These have made SOFCs promising for applications in power generation, transportation, and combined heat and power (CHP) systems.

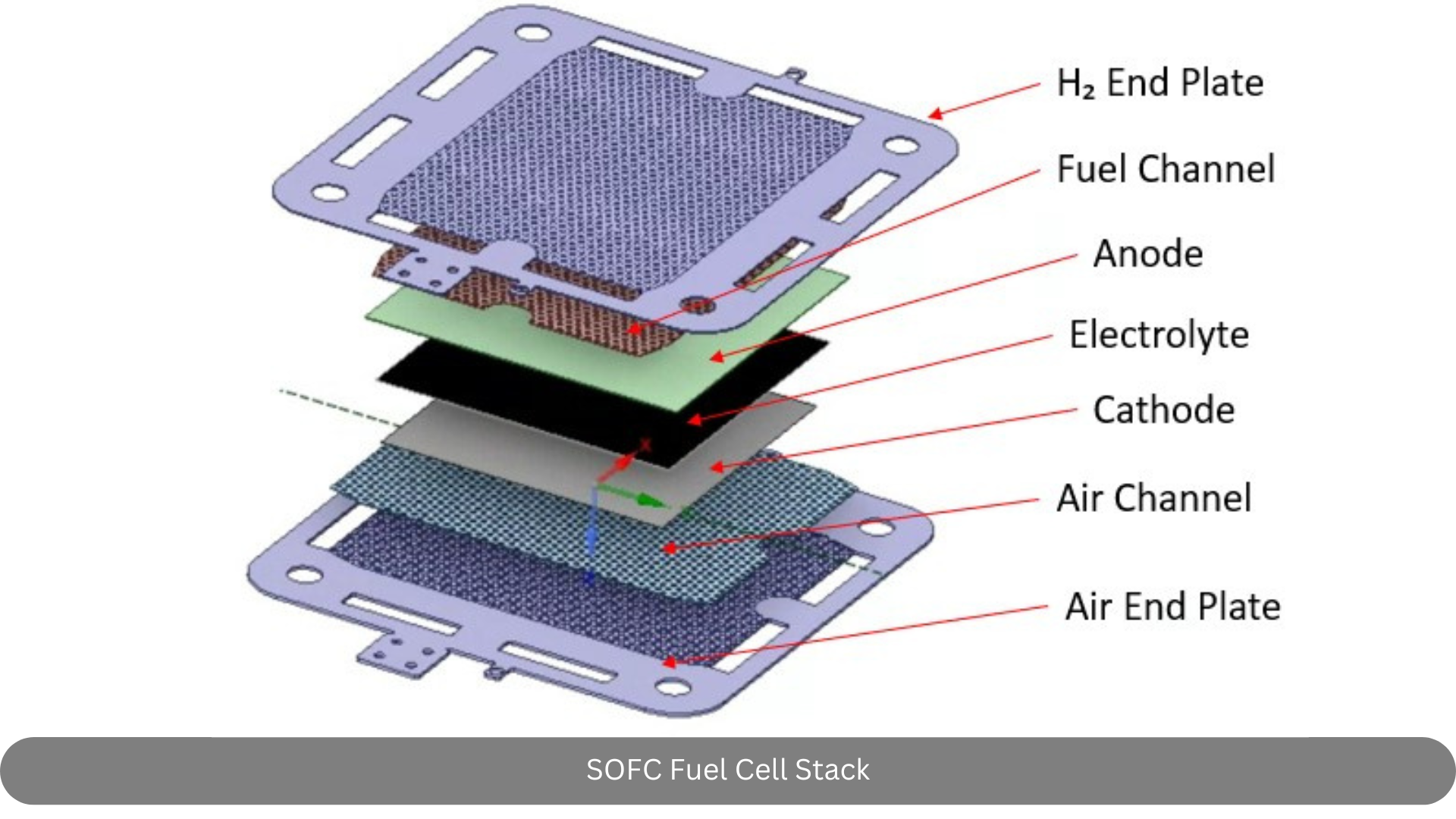

This project, led by the University of Alberta (UAlberta), in partnership with two industry partners develops the first demonstration-scale 0.5 kW solid oxide fuel cell (SOFC) stack as a combined heat and power (CHP) unit for residential applications in Canada. Such CHPs at the scale of 5 kW are meant to deliver clean heat and electricity to Canadian households. Currently, the power degradation rate of commercial 1 to 5-kW SOFC stacks is about 1% per 1000 hours, exceeding the required 0.2% degradation rate to make SOFCs a commercially viable technology.

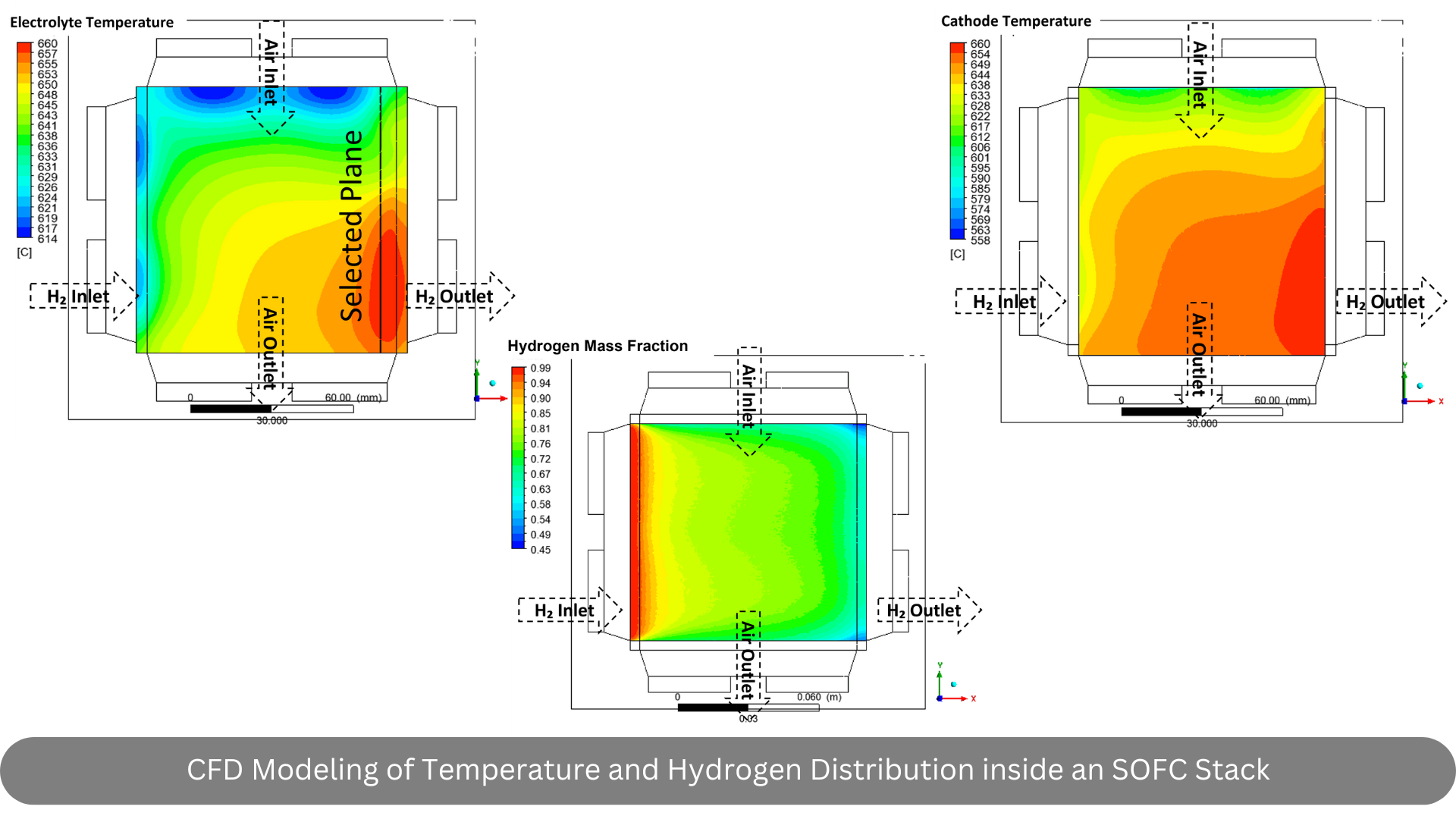

The objective of this project is to reduce the power degradation rate of the demo scale CHP to below 0.2% per 1000h and increase its fuel conversion efficiency to higher than 90%. This target will be achieved by developing large planar fuel cells using novel cathode materials developed at UAlberta, optimizing the stack design using computational fluid dynamics (CFD), and controlling the operation of the stack using innovative artificial intelligence and machine learning techniques. Given the elevated carbon intensity of both space heating and Alberta's grid, this technology has the potential to substantially reduce emissions in Alberta. Extending the longevity of CHP systems to nearly 15 years by 2050 yields significant advantages for Alberta including a reduction of 1.5 Mt CO2 emission.

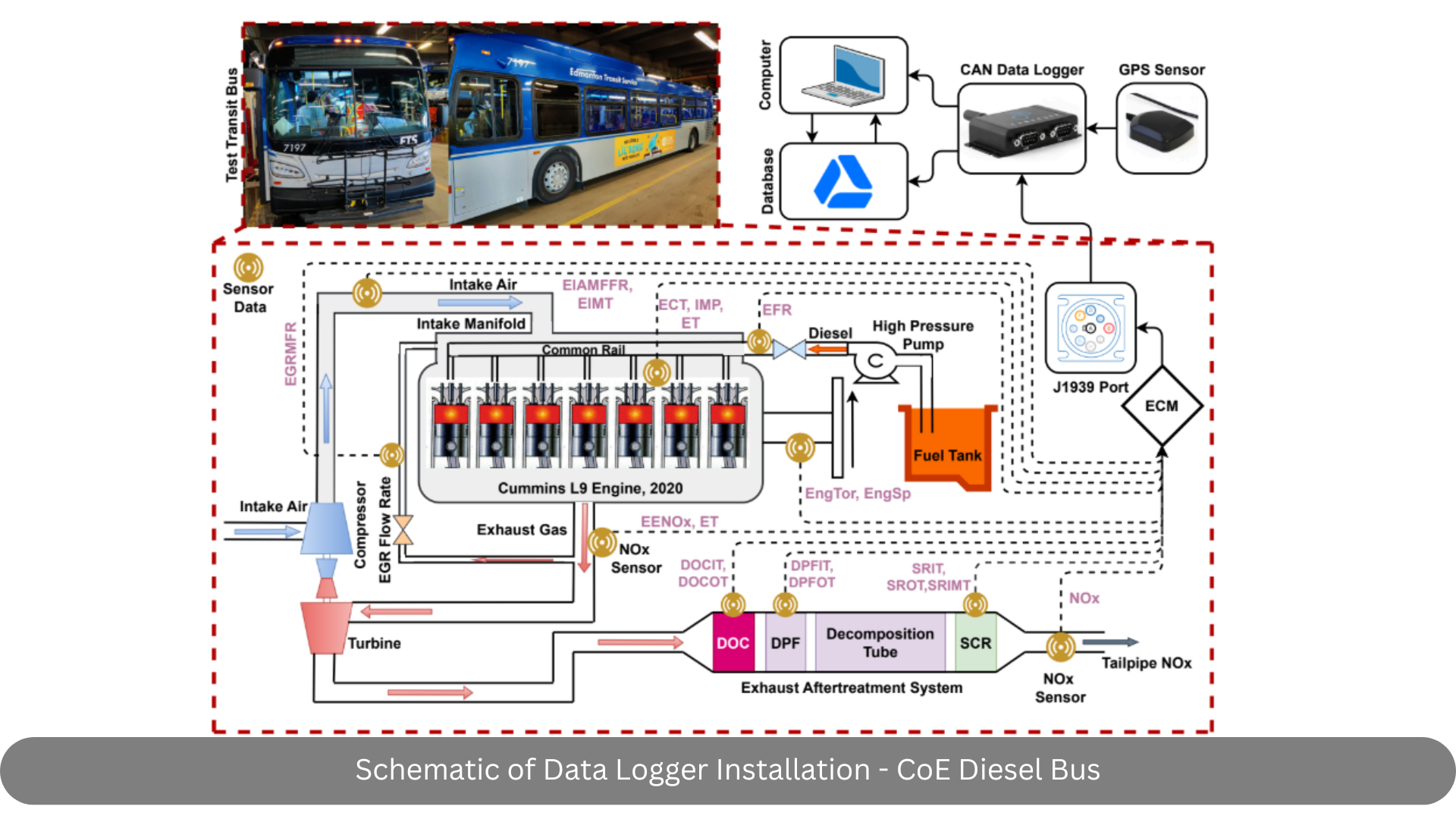

AZEHT (Alberta Zero-Emissions Hydrogen Transit)

The AZEHT (Alberta Zero-Emissions Hydrogen Transit) project is focused on advancing the understanding and performance of PEM fuel-cell bus technologies under various operational conditions. In this project, the EML team has gathered comprehensive data, surpassing 260,000 kilometers, on three bus types: diesel, electric, and fuel-cell, which service routes for both the City of Edmonton and Strathcona County. This data spans five buses from multiple manufacturers, encompassing diverse parameters like fuel efficiency, power output, and environmental impact.

Our analysis leverages these detailed datasets to assess real-world energy consumption, maintenance requirements, and overall reliability. Key insights include understanding the energy demands across different urban and interurban routes and assessing the seasonal variations in performance, especially the impact of colder climates on battery efficiency and fuel cell reliability. This data will inform recommendations for an optimized mixed fleet that aligns with energy and emission reduction goals while providing robust transit options for these regions.

Alberta Zero Emission Truck Electrification Collaboration (AZETEC)

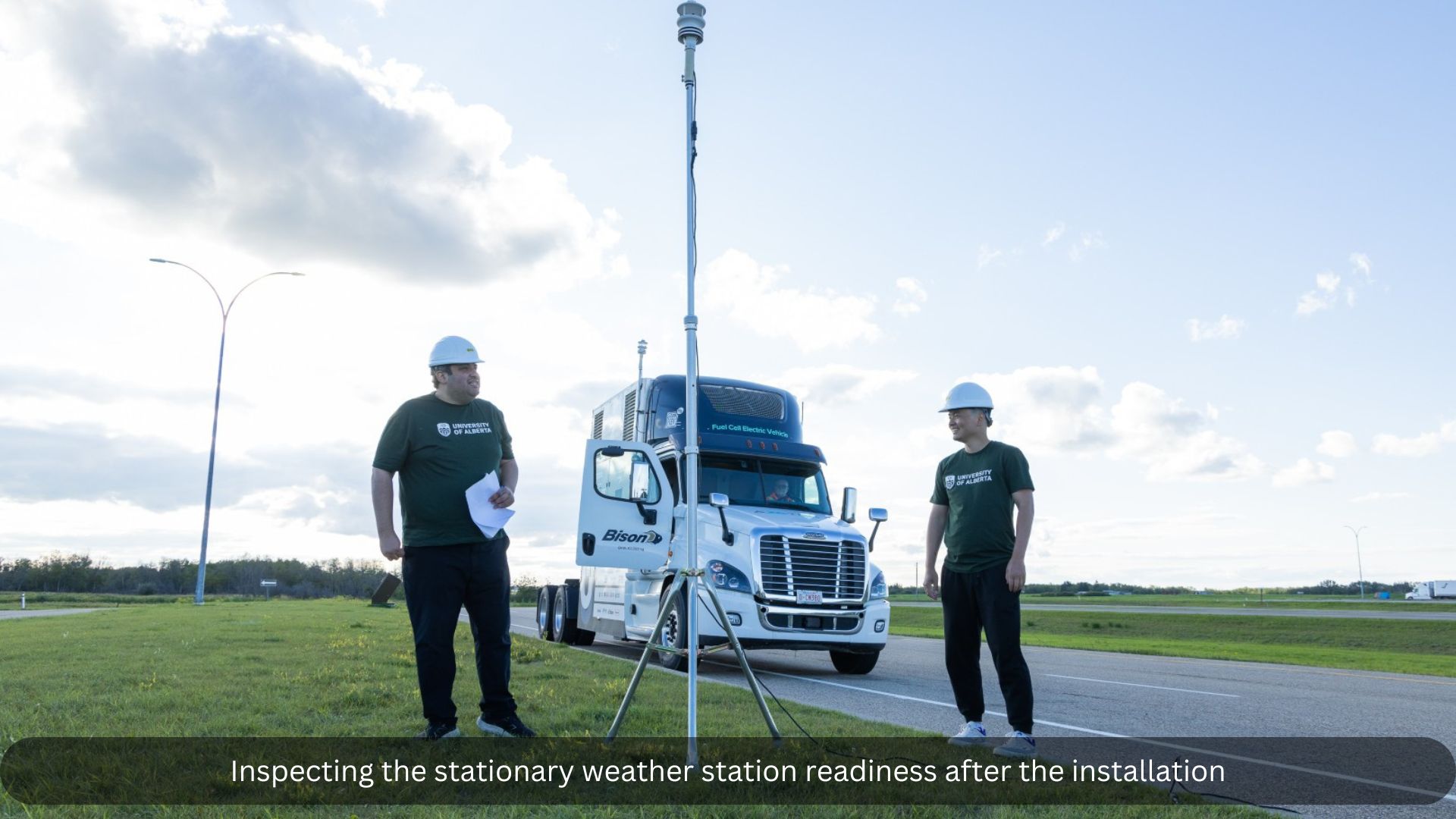

In this project, the EML team analyzes two 64-ton fuel cell heavy duty trucks that are powered by PEM fuel cells manufactured by Ballard Power Systems, integrated with a lithium-ion battery pack into a hybrid electric drive designed by Dana. These systems are built on a Freightliner Cascadia Class 8 truck platform.

The study aims to examine the effects of controlled variables, such as cargo loads, truck velocity, and driving modes (cruising, acceleration, deceleration), as well as uncontrolled variables, including ambient temperature, wind speed, and traffic conditions (acceleration/deceleration frequency), on the trucks’ performance. Additional objectives include investigating the trucks’ maximum driving range, analyzing powertrain efficiency compared to conventional diesel trucks, and evaluating cold-start capability at ambient temperatures ranging from -10℃ to -30℃.

This study will also compare the AZETEC trucks' energy consumption with that of traditional diesel trucks, examining how climate factors (ambient temperature, humidity, wind) impact energy use, as well as cabin climate conditioning capability and its effects on energy efficiency. The trucks' performance will first be evaluated through baseline testing, including cruising and range tests with different cargo loads, followed by a performance evaluation during commercial operation.

Zero Emission Truck Testbed (ZETT)

In this project, the EML team analyzes and evaluates the performance of three fuel cell Class 8 trucks—manufactured by Nikola, Hyzon, and the AZETEC prototype—will be tested on various routes within Alberta. Additionally, the performance of a battery-electric truck will be evaluated during its commercial operation between British Columbia in Canada and Washington State in the US. The three fuel cell trucks will undergo baseline testing against a conventional diesel truck to compare the technologies. This testing will include a series of road evaluations, such as cruising tests, range assessments, and driving on high-slope roads, among other scenarios.

The study’s objectives are to analyze the impact of factors such as cargo loads, truck velocity, driving modes (cruising, acceleration, deceleration), ambient temperature, wind speed, and traffic conditions (acceleration/deceleration frequency) on the trucks’ performance. Additional goals include investigating the vehicles’ maximum driving range and analyzing powertrain efficiency in comparison to conventional diesel trucks. The study will also assess energy consumption relative to traditional diesel trucks, examining the influence of climate factors (ambient temperature, humidity, and wind) on energy use, as well as the effects of cabin climate conditioning on energy efficiency.