Research Laboratories

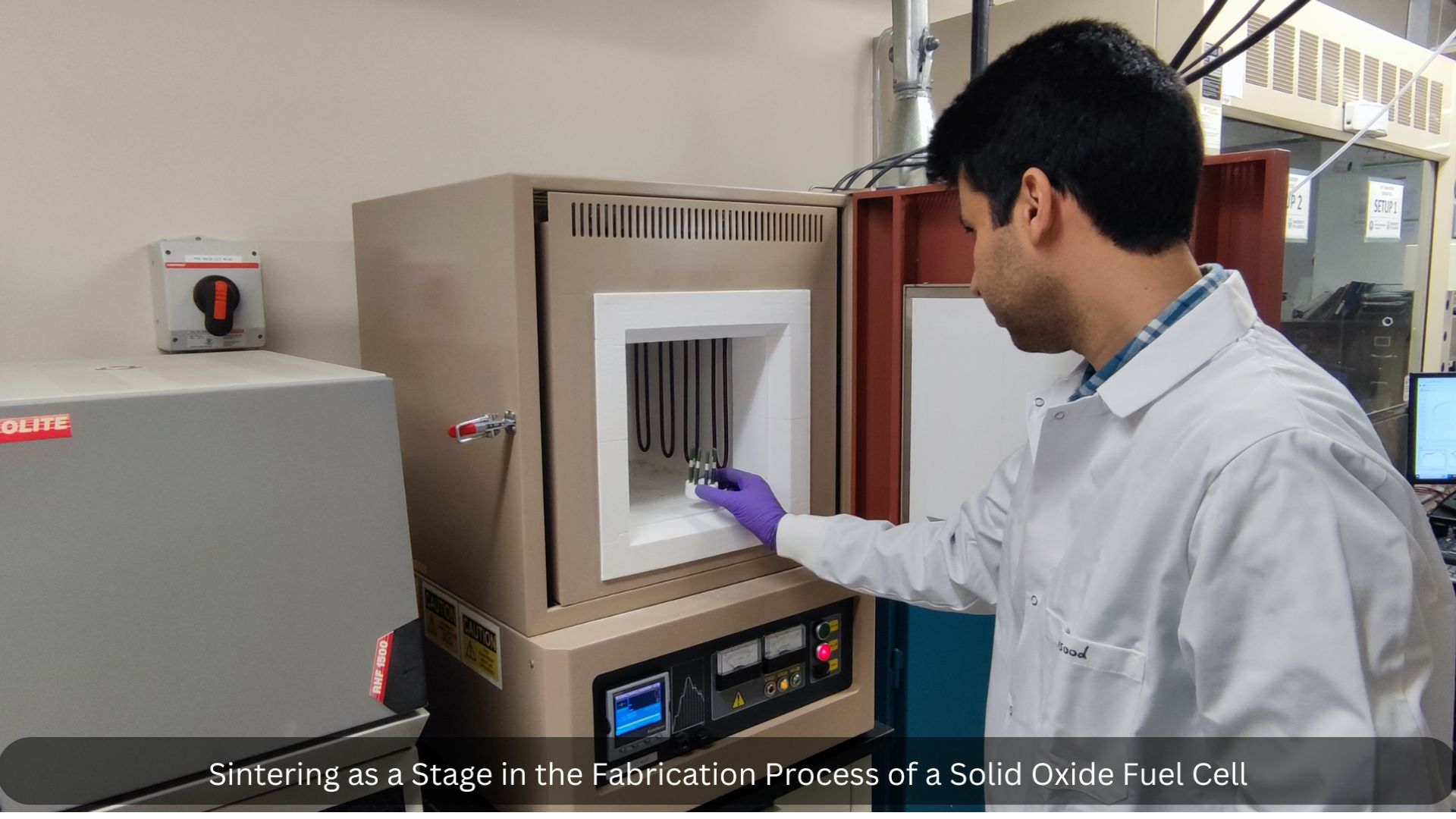

Solid Oxide Fuell Cell Laboratory

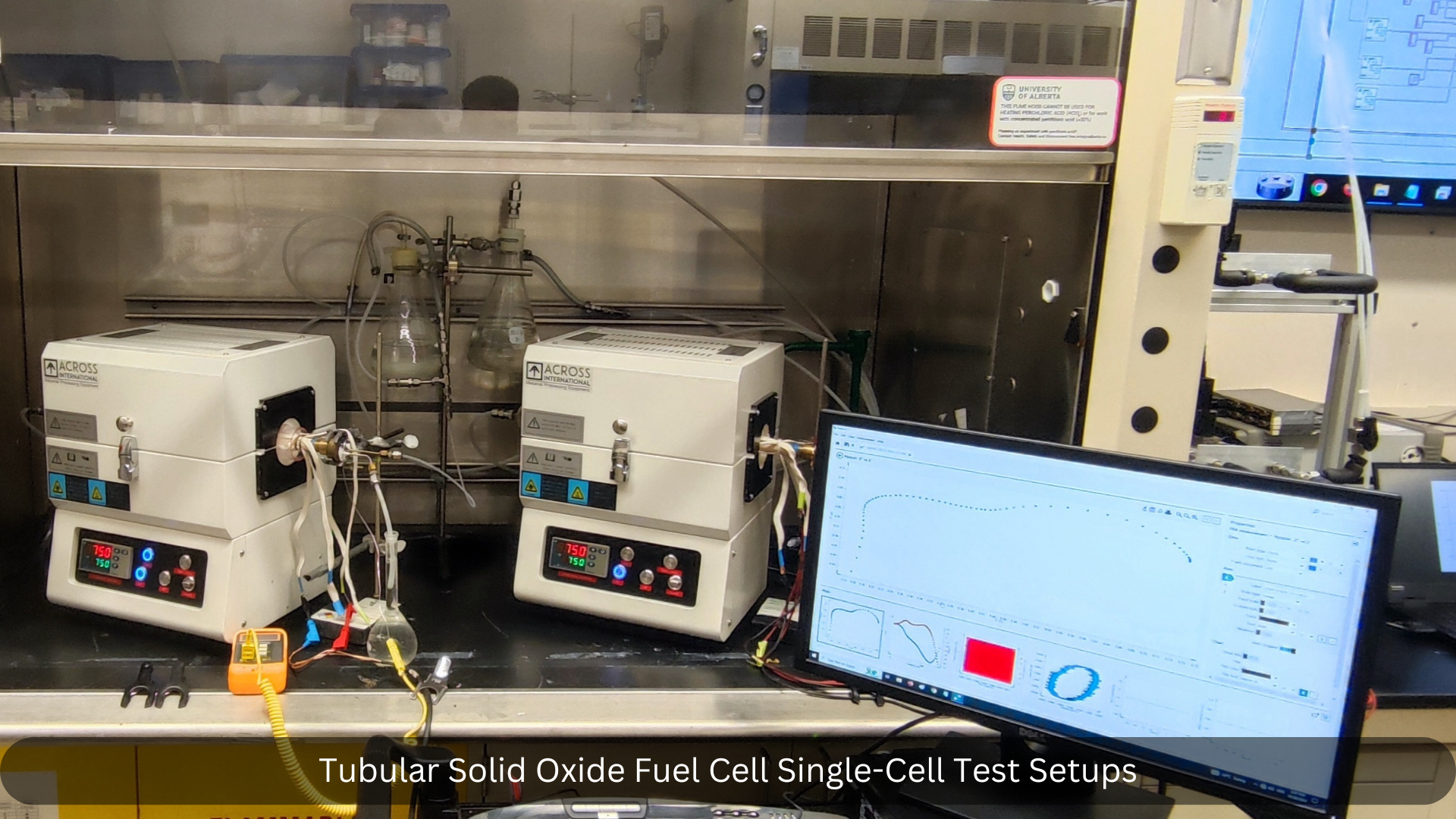

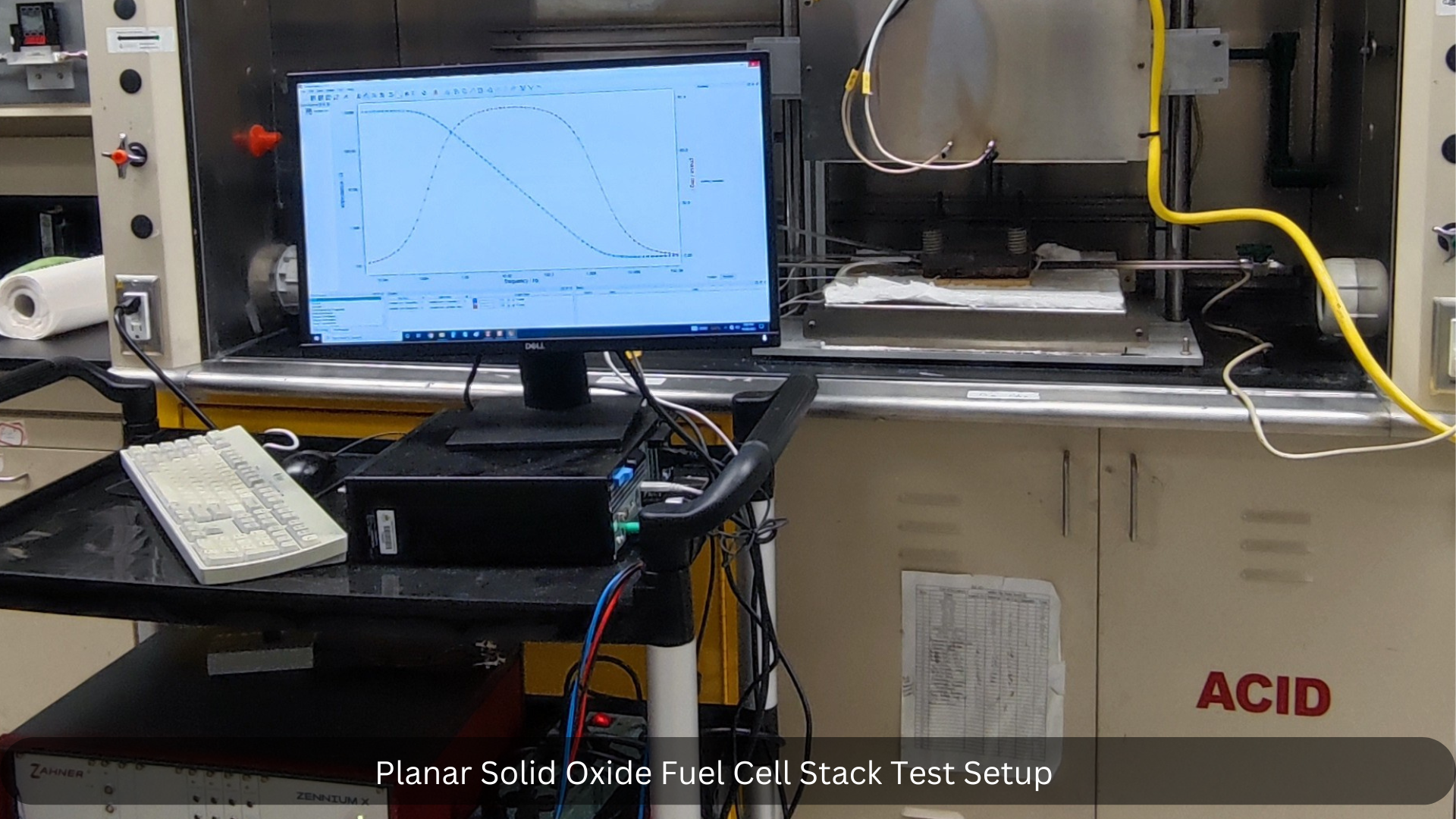

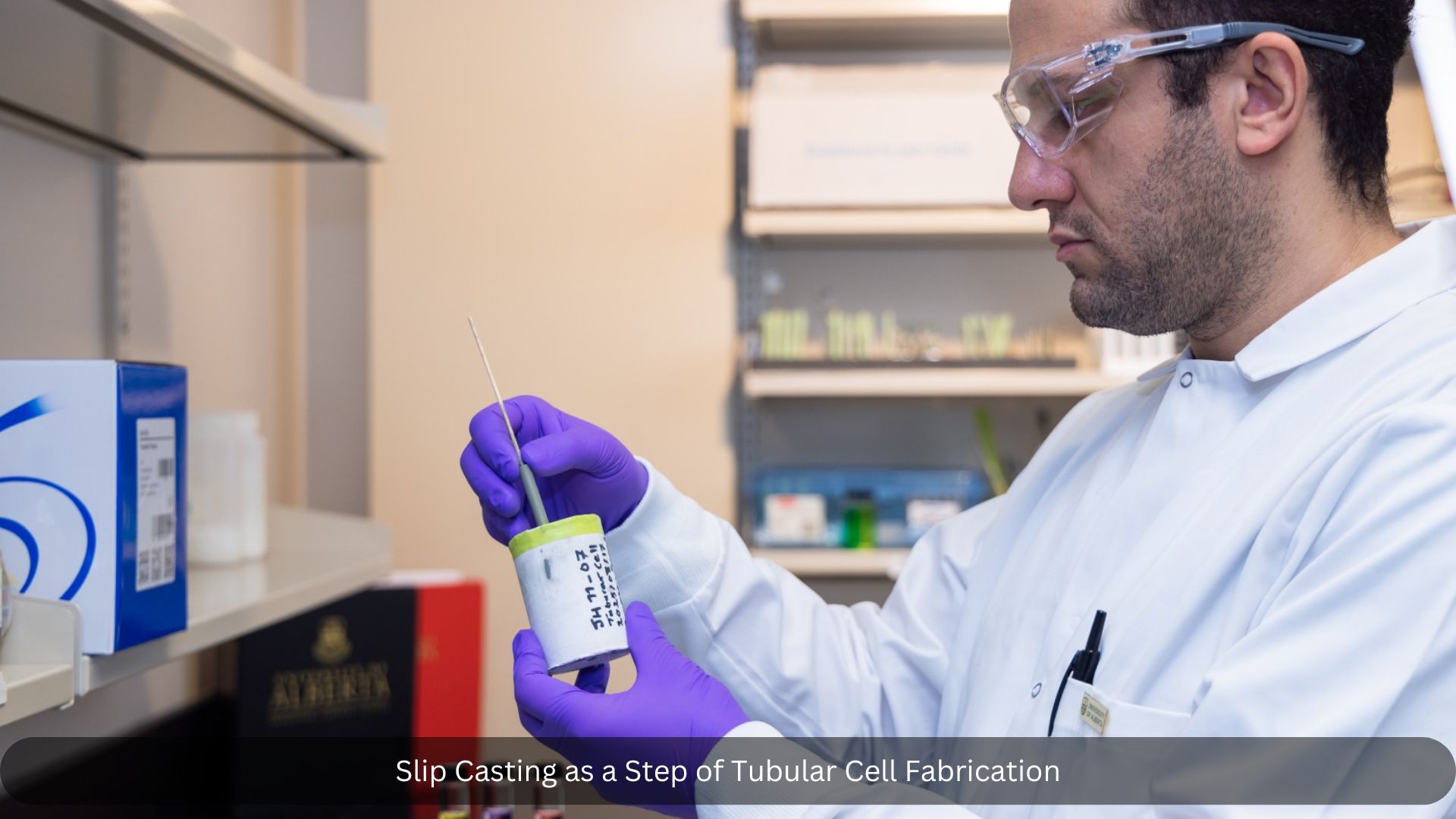

This laboratory focuses on the design, fabrication, and testing of tubular and planar solid oxide fuel cells (SOFCs) at both single-cell and stack levels. A comprehensive range of equipment, including ball mill, planetary ball mill, vibro-mill, shaker, dip coater, tape casting machine, screen printer, vacuum oven, and tube furnaces with controlled atmospheres, as well as muffle furnaces capable of operating at temperatures up to 1500°C, enables us to process ceramic powders into layered cell structures. The thickness of these layers varies from a few microns to several hundred microns.

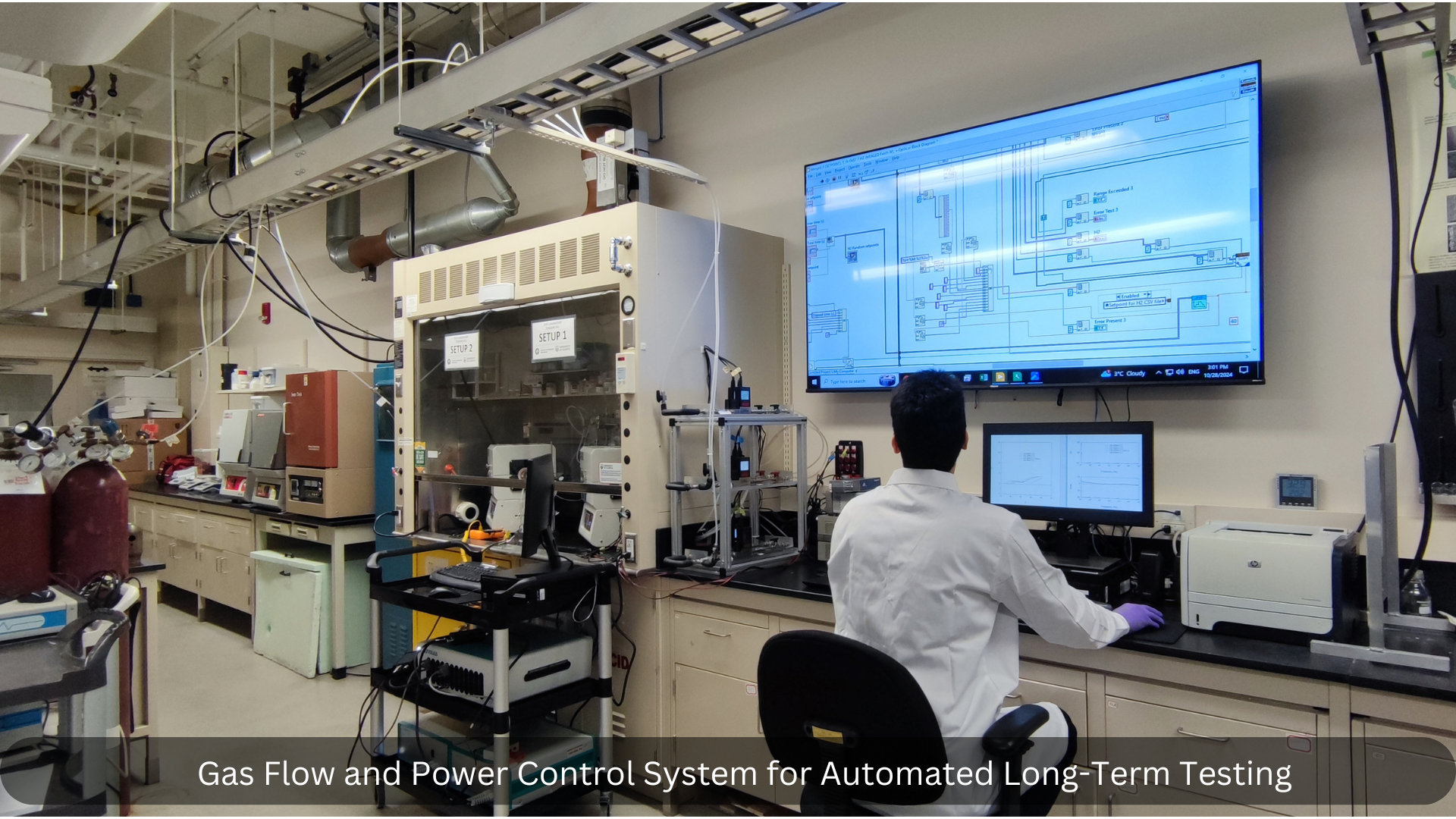

For fuel cell testing, bell-type or tube furnaces are employed, enabling long-term operation of cells at temperatures up to 1000°C. An advanced suite of flow controllers, thermocouples, DC loads, and state-of-the-art potentiostats ensures precise control and programming of temperature, gas flow rates and compositions, as well as current and voltage up to 1 kW. Furthermore, this laboratory is equipped to conduct simultaneous Electrochemical Impedance Spectroscopy (EIS) testing on up to 17 cells within a stack. Samples intended for microscopic analysis can be polished in this laboratory using a semi-automatic polisher."

Vehicle Testing

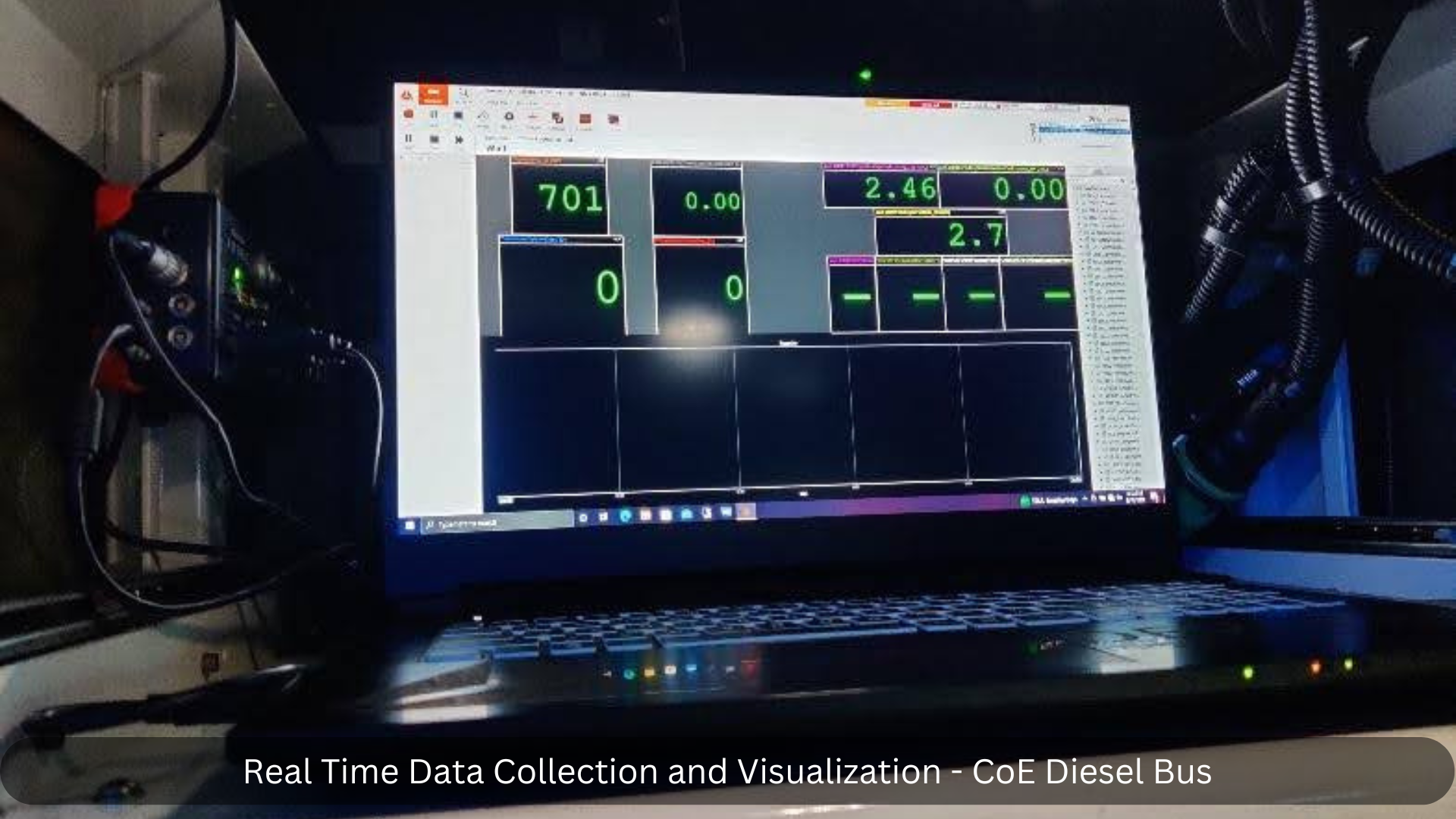

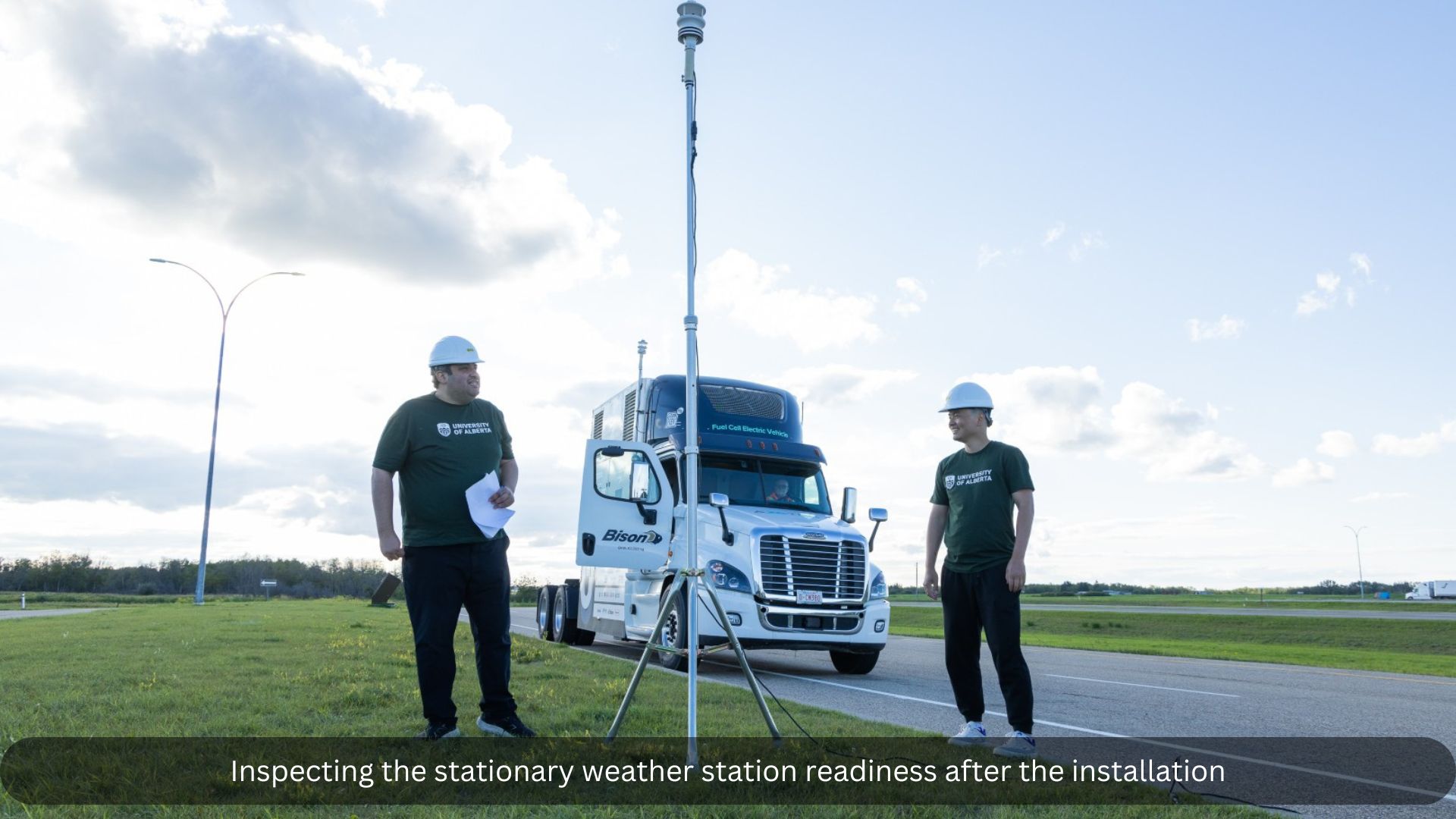

Our Vehicle Testing Laboratory is equipped with state-of-the-art tools designed to support advanced testing and analysis for both light and heavy-duty vehicles. We use three types of CAN data loggers: CANedge, Dewesoft, and Frimatix. We use these to monitor and measure vehicle energy consumption and performance. These devices capture real-time data from the vehicle's CAN bus network, enabling detailed analysis of parameters like fuel consumption, vehicle performance, and powertrain efficiency. The data can be stored on SD cards for offline analysis or uploaded directly to a portal for immediate processing, providing flexibility for a wide range of testing scenarios.

To ensure accurate measurement of real-world emissions, we utilize a Portable Emissions Measurement System (PEMS). This system allows us to assess pollutants such as CO2, NOx, and particulate matter during actual vehicle operation, providing critical insights into environmental impact under different driving conditions. The PEMS setup is essential for regulatory compliance and for developing cleaner vehicle technologies.

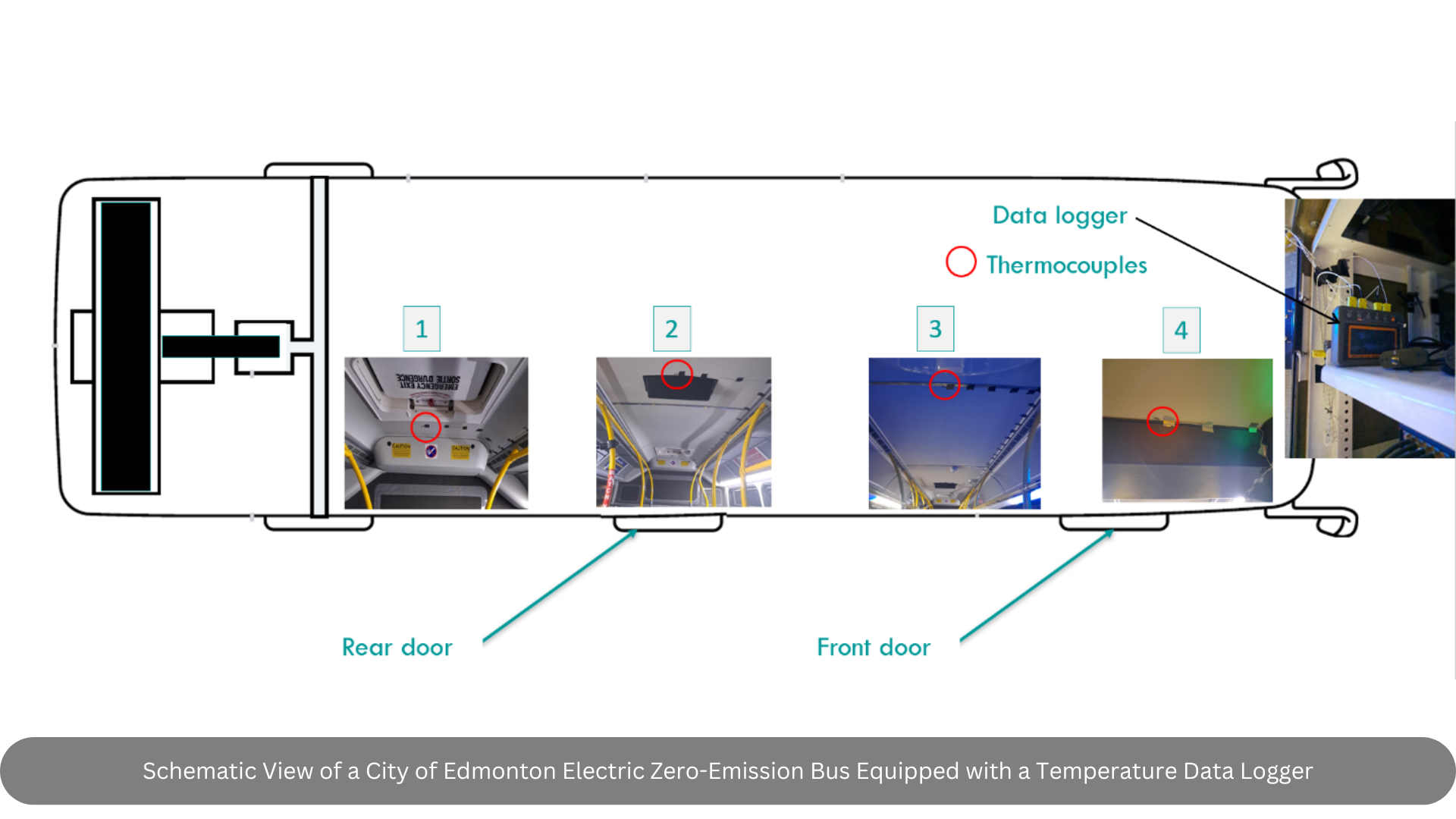

For thermal comfort and energy efficiency studies, we have specialized cabin temperature sensors and data loggers to monitor and record the interior temperature of heavy-duty vehicles. These tools help evaluate HVAC system performance and ensure optimal thermal management for vehicle operators under varying conditions.

Additionally, our lab is equipped to test and analyze vehicle performance across a variety of applications:

- Energy consumption measurement: Analysis of power usage for both traditional and alternative fuel vehicles.

- Real-time data acquisition: Using tools like CANedge and Dewesoft for synchronized multi-sensor data collection, including GPS and accelerometer inputs.

- Fleet monitoring: Capabilities to assess fleet-wide performance using advanced data loggers and cloud-based platforms for centralized reporting and analysis.

These capabilities enable us to provide comprehensive insights into vehicle performance, emissions, energy consumption, and thermal management. Together, this infrastructure supports cutting-edge research aimed at advancing cleaner, more efficient, and sustainable transportation technologies.

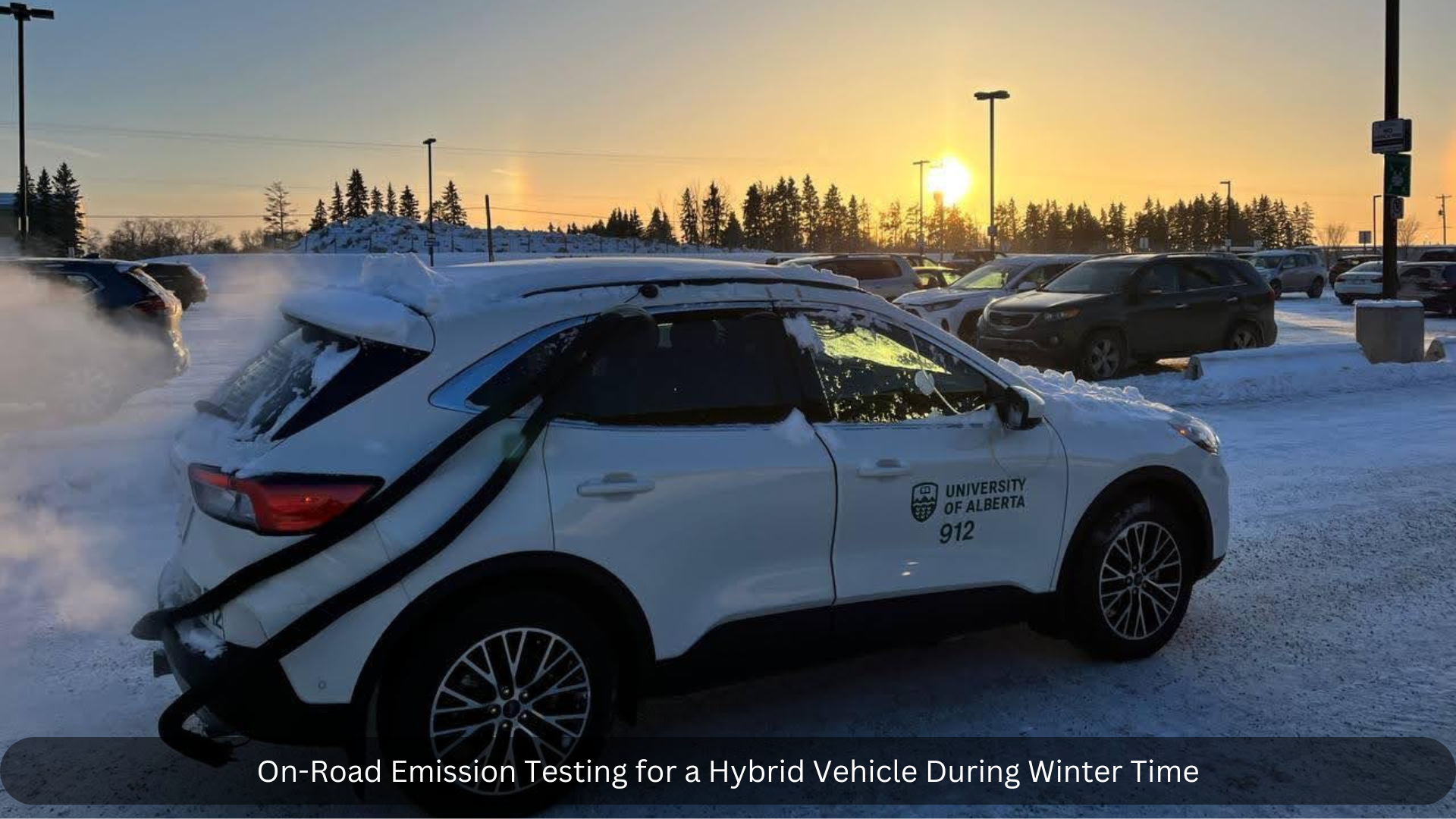

On-Road Emission Testing with PEMS Technology

At EML, we are committed to advancing the understanding of real-world vehicle emissions and their impact on air quality and the environment. To achieve this, we utilize portable emission measurement system (PEMS) to conduct on-road emission testing under a wide range of conditions and vehicle types.

PEMS technology allows us to measure vehicle emissions directly under real-world driving conditions, providing accurate and reliable data that reflects actual vehicle performance. Unlike laboratory testing, PEMS captures emissions during diverse driving scenarios, including urban, rural, and highway conditions, ensuring a comprehensive assessment of environmental impact. Our systems measure key pollutants such as CO2, NO, CO, unburned hydrocarbons, and particulate matter (PM) in real-time, while also evaluating emissions under dynamic driving conditions, such as varying speeds, loads, and road gradients. Our PEMS systems could be directly connected to the vehicle’s engine control unit (ECU) to access important engine data such as engine load, speed, and fuel consumption. This integration enables the PEMS to deliver emission data on a mass basis. To guarantee the precision and reliability of our emission measurements, we have our own calibration station to calibrate PEMS equipment. Regular calibration ensures that the recorded readings are accurate and consistent which allows us to deliver trusted high-quality data.

Unique Testing Expertise

Our team has extensive experience testing vehicles in extreme cold weather conditions, with temperatures reaching as low as -35°C. This allows us to evaluate emissions performance in some of the most challenging environments, providing critical insights into how vehicles operate in real-world winter conditions.

We have also conducted PEMS testing on a diverse range of vehicles, including:

- Dual-fuel hydrogen-diesel trucks

- Hybrid Vehicles

- Gasoline Powered Vehicles

- Diesel Powered Vehicles

This breadth of experience enables us to understand the emission profiles of various propulsion technologies and fuels, contributing to the development of cleaner and more efficient transportation solutions.

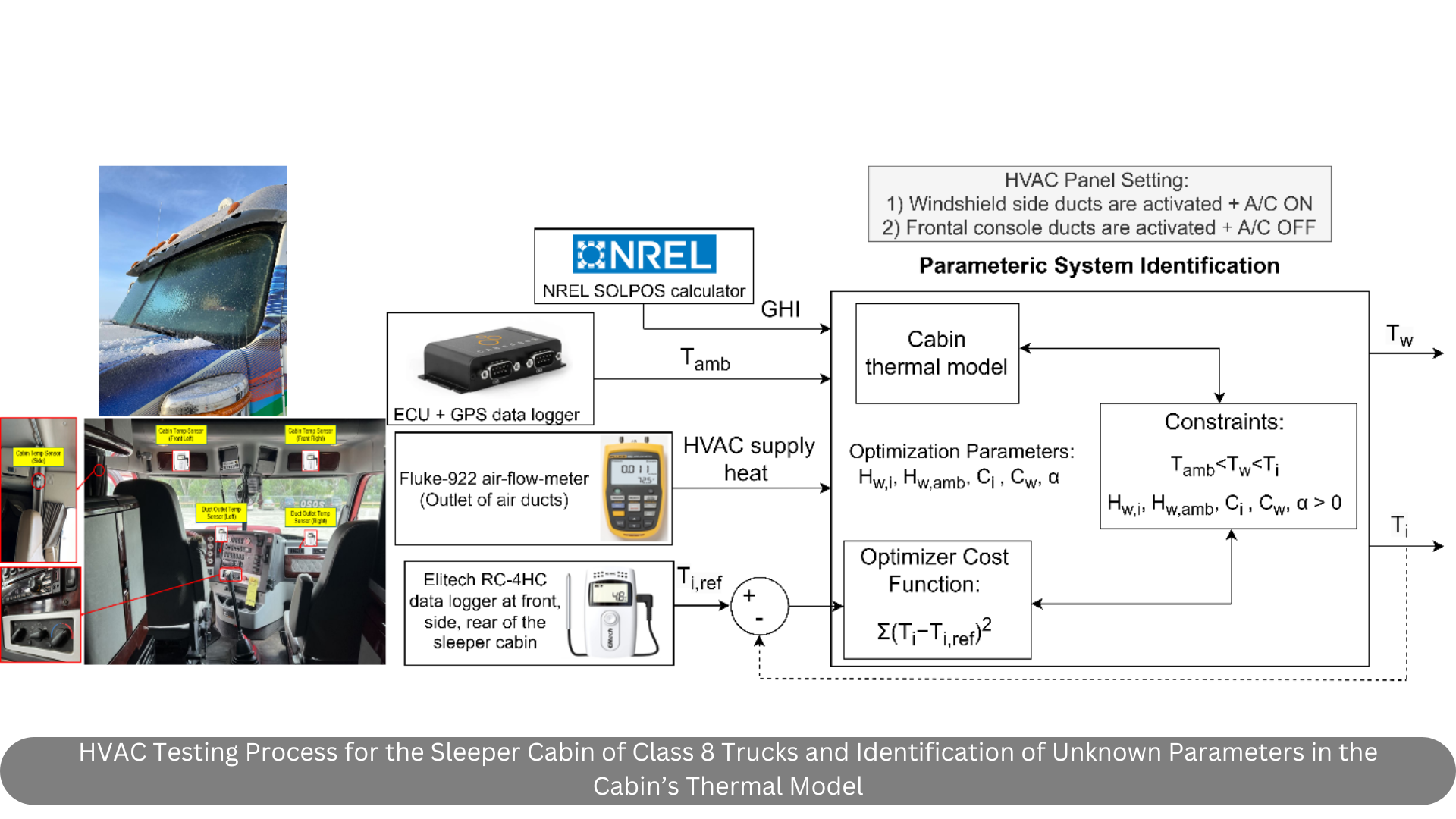

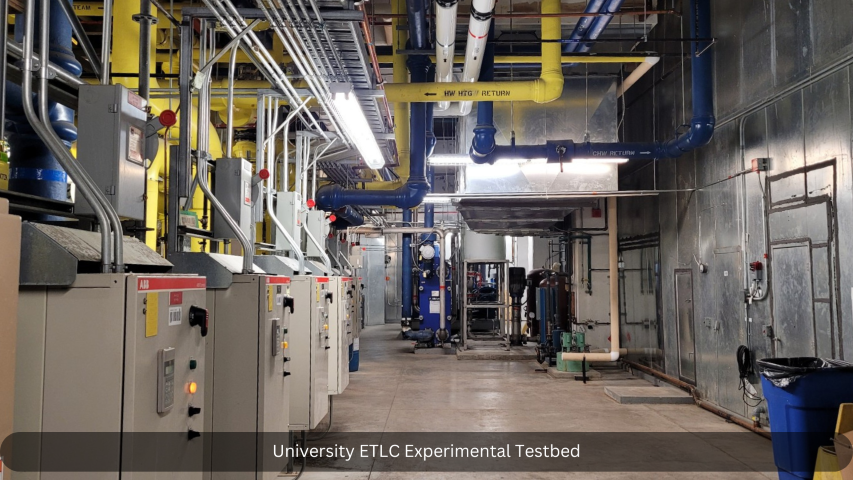

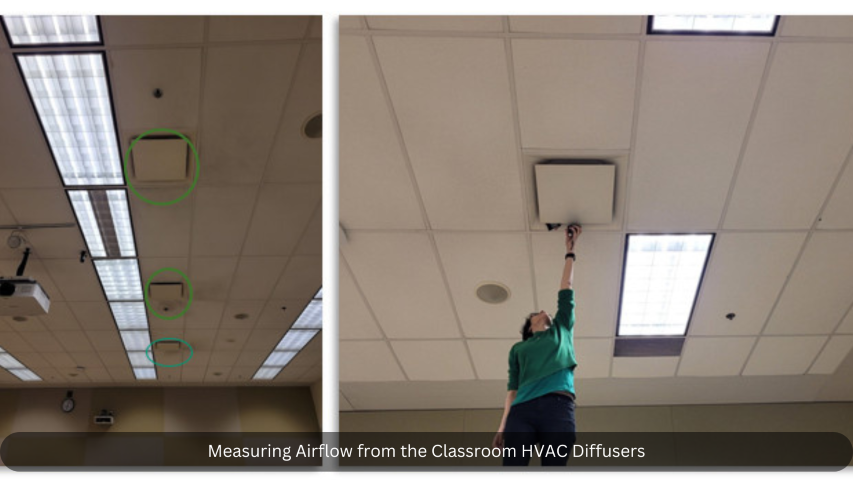

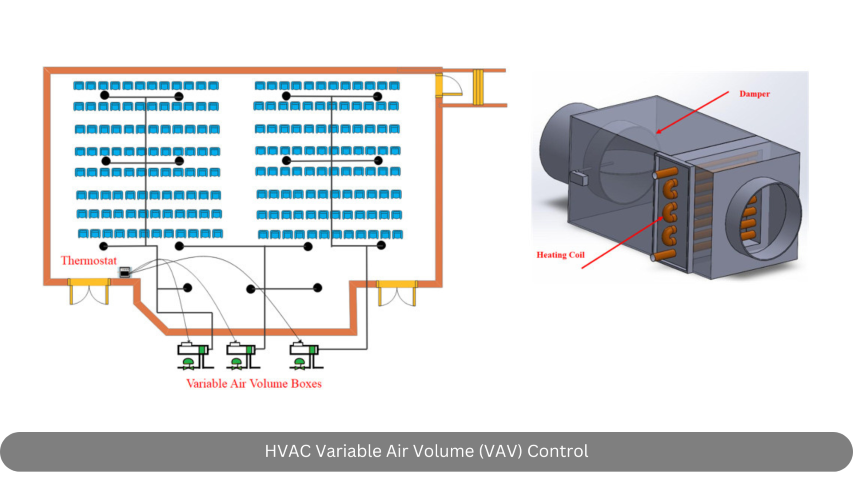

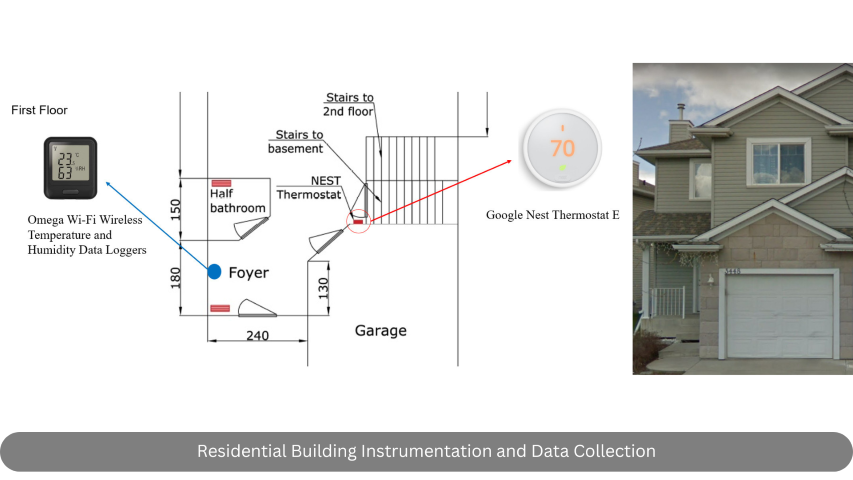

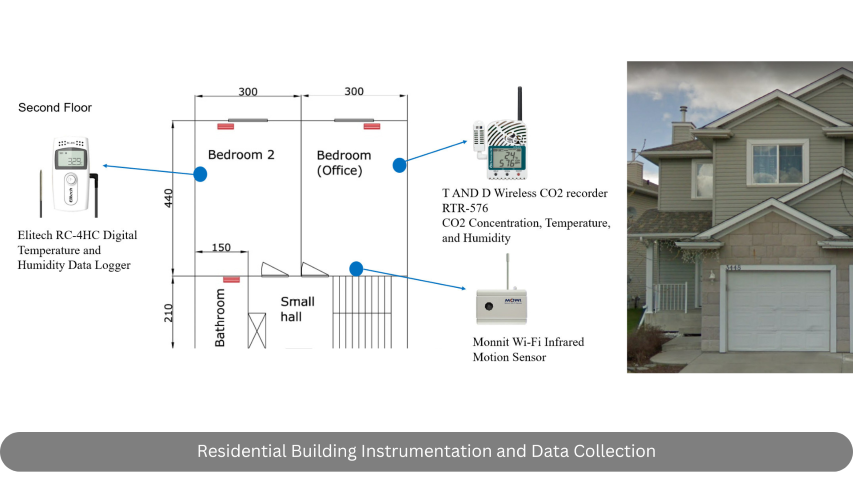

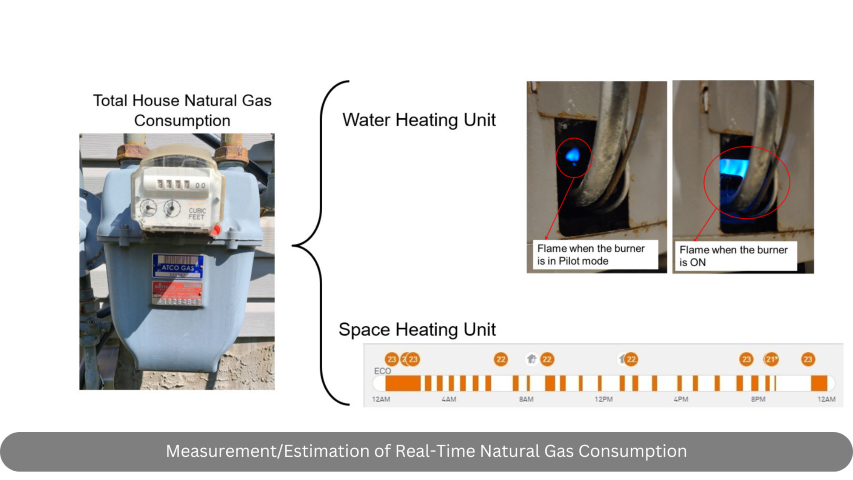

HVAC Testing

Energy Mechatronics Laboratory (EML) offers expertise and capabilities for HVAC instrumentation, modeling, estimation and intelligent controls. To this end, EML has a range of equipment for measuring HVAC related parameters such as

- Temperature, and thermal distribution,

- Pressure,

- Relative humidity,

- CO2 level,

- Mass and volume flow rates,

- Compressor load,

- Wind velocity and angle.

EML has been involved in various projects including HVAC in buildings, as well as Air Conditioning in commercial and passenger vehicles. These have included instrumentation and testing of buildings and vehicles for data collection and analysis. The data were often used to design predictive models for optimization and intelligent controls.