Lab Equipment

CDAM lab tour video

This video showcases the lab capacity for conducting sample preparation, materials characterization, and mechanical testing. We are in close collaboration with nanoFAB, which is a Canadian-leading and government-funded materials characterization and microfabrication laboratory located at the University of Alberta (nanoFAB).

Shimadzu HPVX-2 ultra-high-speed camera

This camera is able to operate up to 10 million frames per second at 400x250-pixel resolution. We have multiple lens arrangements that allow us to achieve resolutions of 8 microns per pixel for 200 ns exposure times. This equipment is unique in Canada, and was funded by the Canada Foundation for Innovation.

Low-speed Promon U750

This camera is able to operate up to 200 frames per second at 1 megapixel resolution, with scaled resolutions up to 1,000 frames per second.

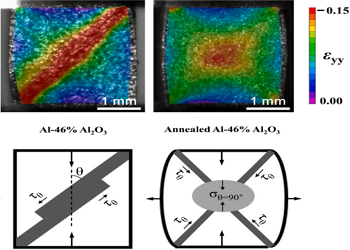

Digital Image Correlation Software (VIC 2D), Correlated Solutions Inc.

This software enables us to provide high-resolution strain measurements of material deformation during experiments. This is important because it can provide insights into damage accumulation during loading and failure. We use this software in conjunction with the cameras in the group.

FLIR x8503sc high-definition thermal camera

A high-definition high-speed infrared camera that is used to study the thermo-mechanical responses of materials, heat transfer problems in materials and fluids, and manufacturing processes. Temperature range measurements are between -20 and 350°C with 1280x1024 resolutions at 180 frames per second. The resolution scales to 320x256 pixels at 1240 frames per second. We have multiple lens arrangements that allow us to achieve 3 microns per pixel. This equipment is unique in Canada, and was funded by the NSERC Research Tools and Instruments program.

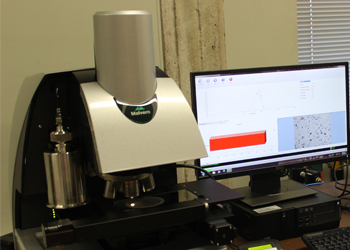

Automated Particle Size Analysis using Malvern Morphologi G3

This equipment enables automated characterization of the size and shapes of particles and fragments. Sizes range from 0.5 microns to 5 mm in a single scan (up to 300,000 particles). We are using this equipment to study fragmentation outcomes during experiments, and wear products and mineral content from industry samples. This equipment is unique in Canada, and was funded by the NSERC Research Tools and Instruments program.

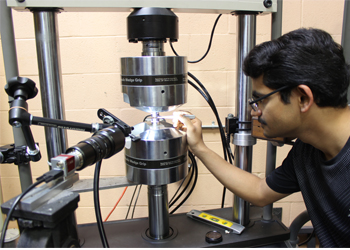

Quasi-Static Testing using an MTS Machine

This machine allows us to study the stress-strain response of materials in compression and tension for strain rates of 10-5 to 10-2 s-1. We have capabilities to test samples at temperatures of -50 to 800 deg C. We can also test granular forms of materials up to hydrostatic pressures of 1.5 GPa.

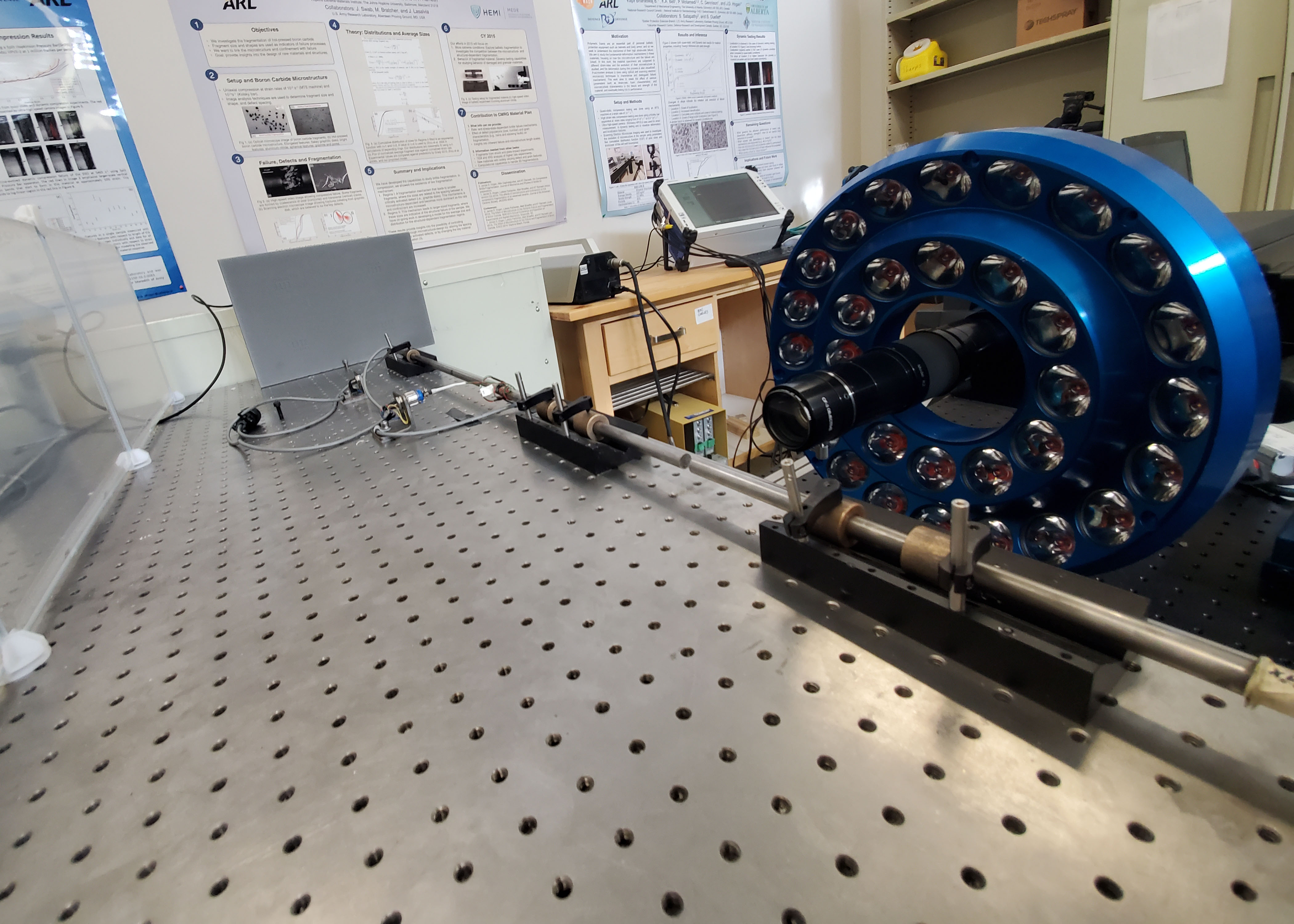

Dynamic Testing using the Compressiong and Tension Split Hopkinson Pressure Bar (Kolsky Bar) systems

This set of equipment allows us to study the stress-strain response of materials in compression and tension for strain rates of 102 to 103 s-1. This system is often coupled with ultra-high-speed imaging for deformation visualization and Digital Image Correlation. It is also integrated with the photon Doppler velocimetry system.

Saw and Polisher

We have an Allied High Tech TechCut 4™ Precision Low Speed Saw and MultiPrep™ Precision Polishing System that are used for sample preparation and dissection.

SVS-Vistek hr25000CCX HR CoaXPress

This camera has 25 Megapixel resolution and is able to capture at 80 frames per second. This is suitable for visualizing localized deformation during quasi-static mechanical testing, and is currently being used in digital image correlation measurements.

Automated macro-hardness indenter- Vickers and Knoop

Capable of automated indentation testing for load ranges 10gf to 2000gf and objectives of 5x, 10x and 50x. Ceramics, metals, and polymers may be tested.

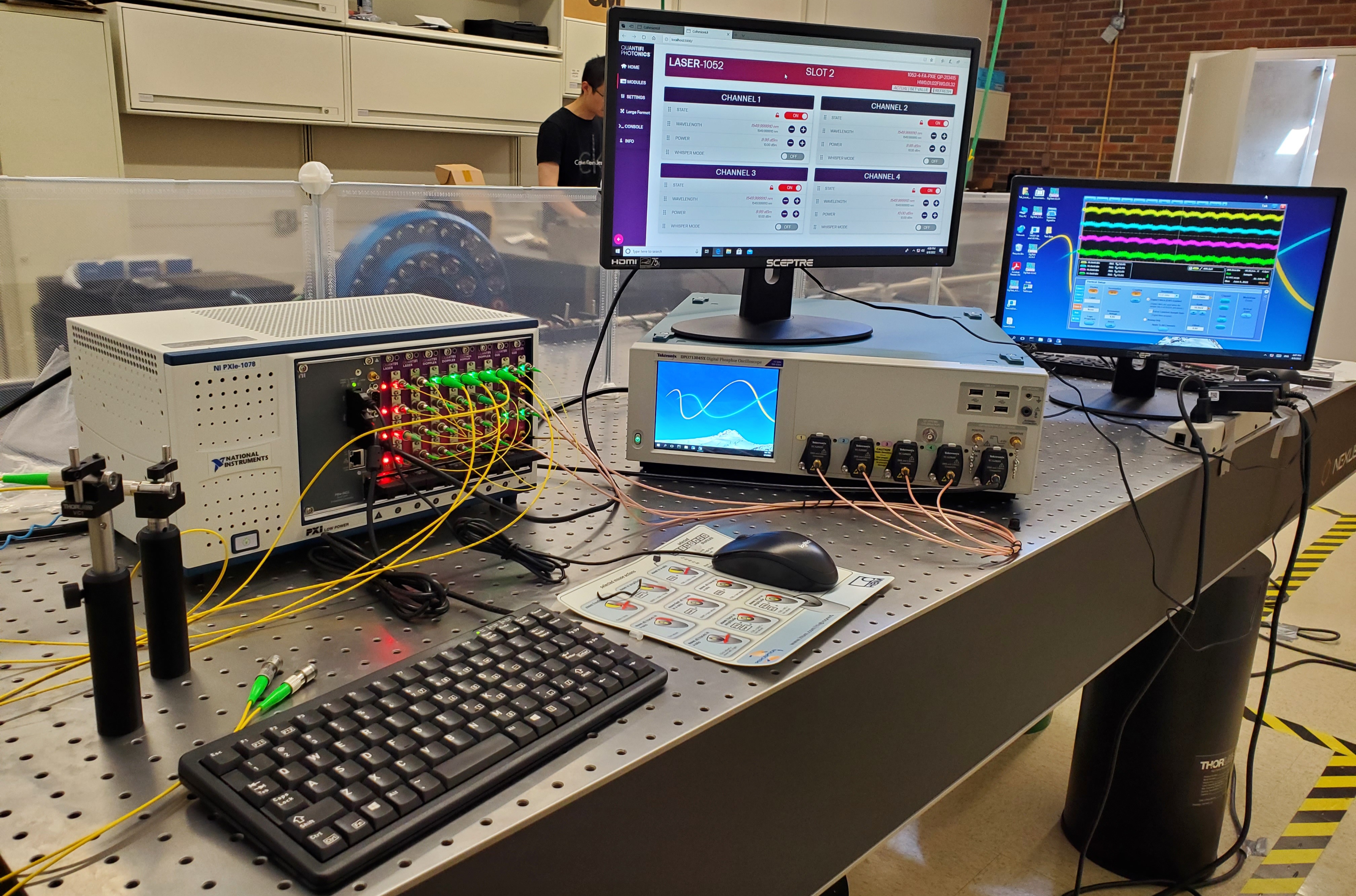

Photon Doppler Velocimetry (PDV) Interferometer System

This PDV system is equipped with Quantifi Photonics modules and a 4-Channel Tektronix oscilloscope with a 13 GHz bandwidth and a 50 GS/s (4h) or 100 G/S (2h) sampling rate, allowing the system to measure velocities up to ~ 10 km/s. The system can be used to study dynamic and shock material and system responses for various applications (e.g., impact and laser welding).

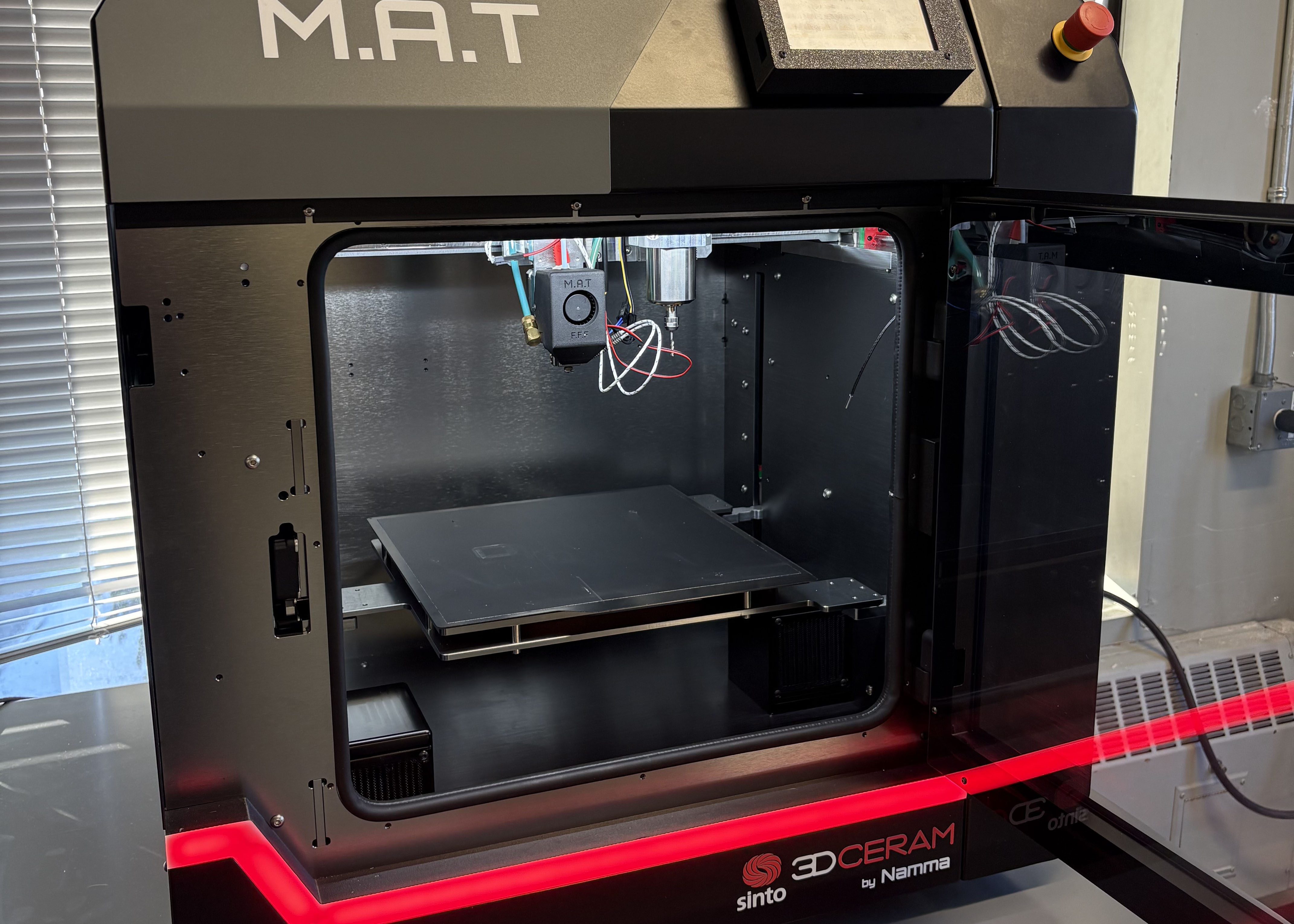

3DCeram Multi Additive Technology 3D Printer

This system is equipped with a fused filament fabrication extruder along with a 250 W CNC mill. This dual-mounted system allows precise fabrication of ceramic green bodies up to 200x200x200 mm3.

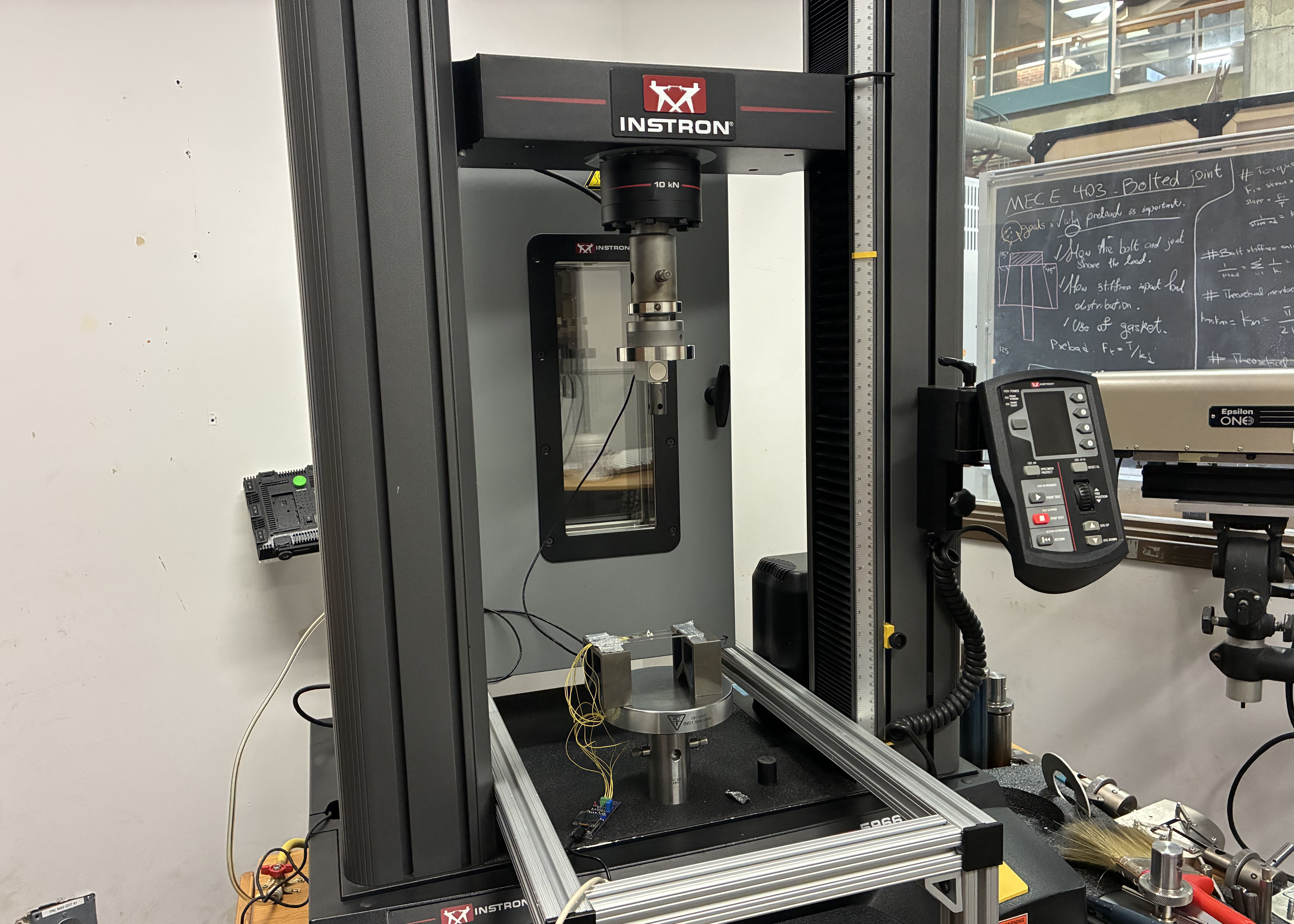

Instron® 3119-600 Series Temperature Controlled Chambers

This chamber offers high-performance environmental control for materials testing across a broad temperature range of -150°C to +350°C. Key features include rapid pull-down times, high-precision Eurotherm controllers, and removable wedge ports for easy setup. These chambers are designed to compensate for extreme thermal conditions during tensile, compression, fatigue, and flexure testing. By ensuring a stable thermal environment, they provide critical data on how polymers, metals, and composites perform under rigorous real-world stresses.