PDFs & Technicians Graduates Undergraduates Past Students

Ryan Going

3rd Year BSc, Mechanical Engineering

Supervisors

Dr. David S. Nobes

Description of Work Term (May - August 2012)

Working for Dr. Nobes has been a terrific experience. As a second-year student, I was thrilled at the opportunity to solve and implement challenging design and data analysis problems in a research-based setting. My work as an Undergraduate Research Assistant over these four months have included designing and building components for use in the Optical Diagnostics Laboratory and writing programs in MATLAB to process images taken by Alireza Setayeshgar in his PhD work with acoustic forces on particles in macro-scale flows.

Hollow glass spheres (~10 um) moving to nodes of an acoustic standing wave in water.

MATLAB Image Processing

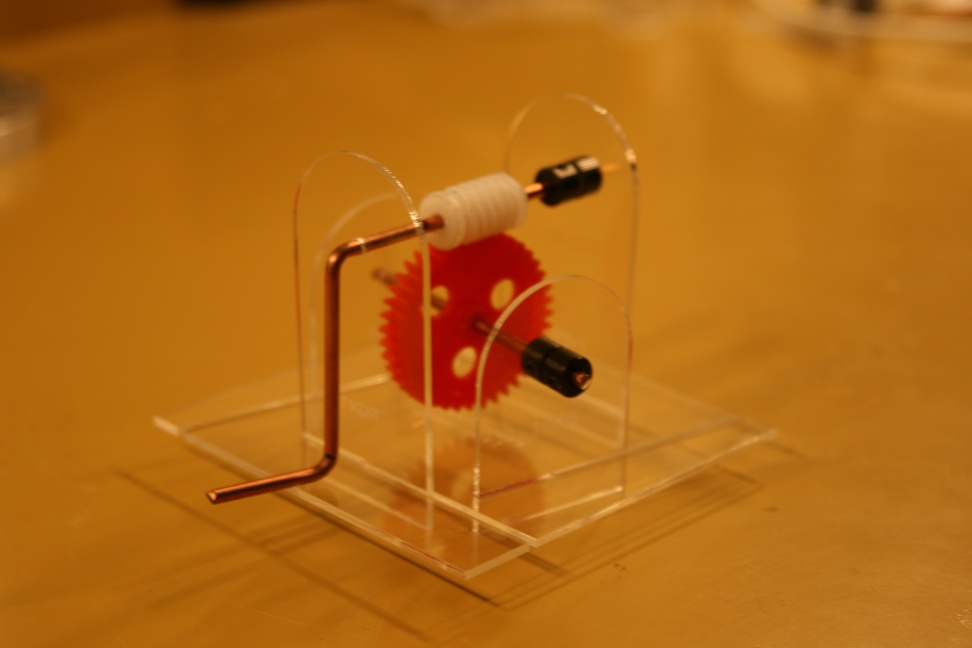

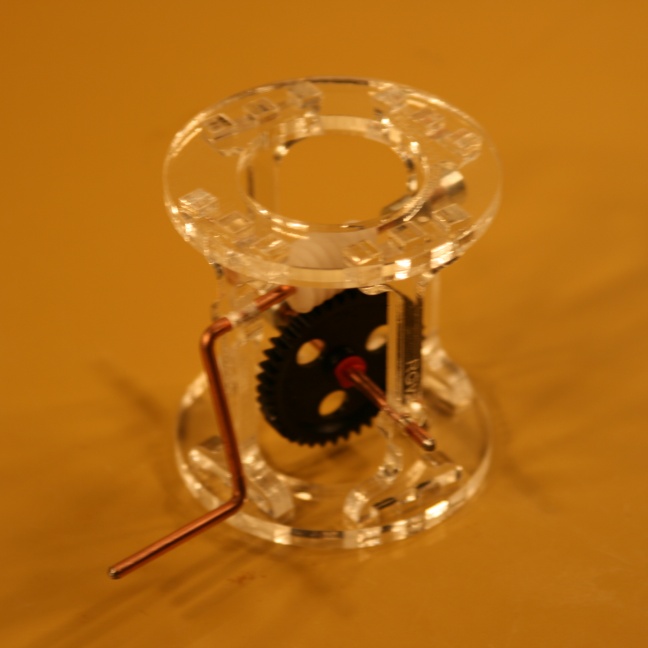

3d Gear Box puzzles (Mark I on left and Mark II on right)

Laboratory Components

Over the course of my four-month work term, I have had the chance to design and build several components for use by several graduate students in their experiments. These include:

- Optic Base plates for use with optic guide rails and breadboards: These plates have slots which fit both metric and imperial optic products from THORLABS and LINOS. The plates allow optic rails to be rigidly fixed to breadboards, or to connect optic rails in series. They are machined from 1/2" anodized aluminum.

- Fluid Channel and cell holder for use by Alireza Setayeshgar: These parts are manufactured entirely from 0.22" plastic sheets which are cut with a VersaLaser engraver and cutter. Assembly is completed with screws and silicone glue. The channel allows fluid to flow in and out of the acoustic cell while fixing it in 3D space in such a way that laser imaging techniques can be used.

- Portable shelving unit for LDV imaging laser: This shelving unit was adapted using an existing server storage rack that was recycled from the Mech E IT department. The rack was modeled in 3D using SolidWorks and wooden shelves were designed and built to house components for the laser, a controller for a 3D traverse, and a dedicated computer.

MATLAB Image Processing

Correlating existing theory with experimental results is the key to validating any scientific procedure. In this regard, I have been helping with Alireza Setayeshgar's PhD experiment which involves close-up imaging of glass particles in micro- and macro-scale flows. My goal was to write a program that could determine the concentration of particles in a fluid based on images taken of the flow. To achieve this, parameters affecting the images were identified, and their influence was measured both qualitatively and quantitatively. These included:

- Camera settings (exposure time, optic zoom level, focus, etc);

- Physical effects (concentration of particles, elapsed time after mixing);

- And how the images were processed.

MATLAB was chosen over DaVis and LabWindows/CVI due to its abundance of built-in functions regarding image processing and its flexibility in coding. In order to determine concentration, an image like the sample on the right (Fig. 1) is taken and converted to a binary image (Fig. 2) based on an intensity threshold. MATLAB then counts the number of particles and finds their average size. Any particles that are too large are not included in the calculation. This filter increases the robustness of the code and prevents flare, bubbles, and other anomalies from being recognized as "particles."

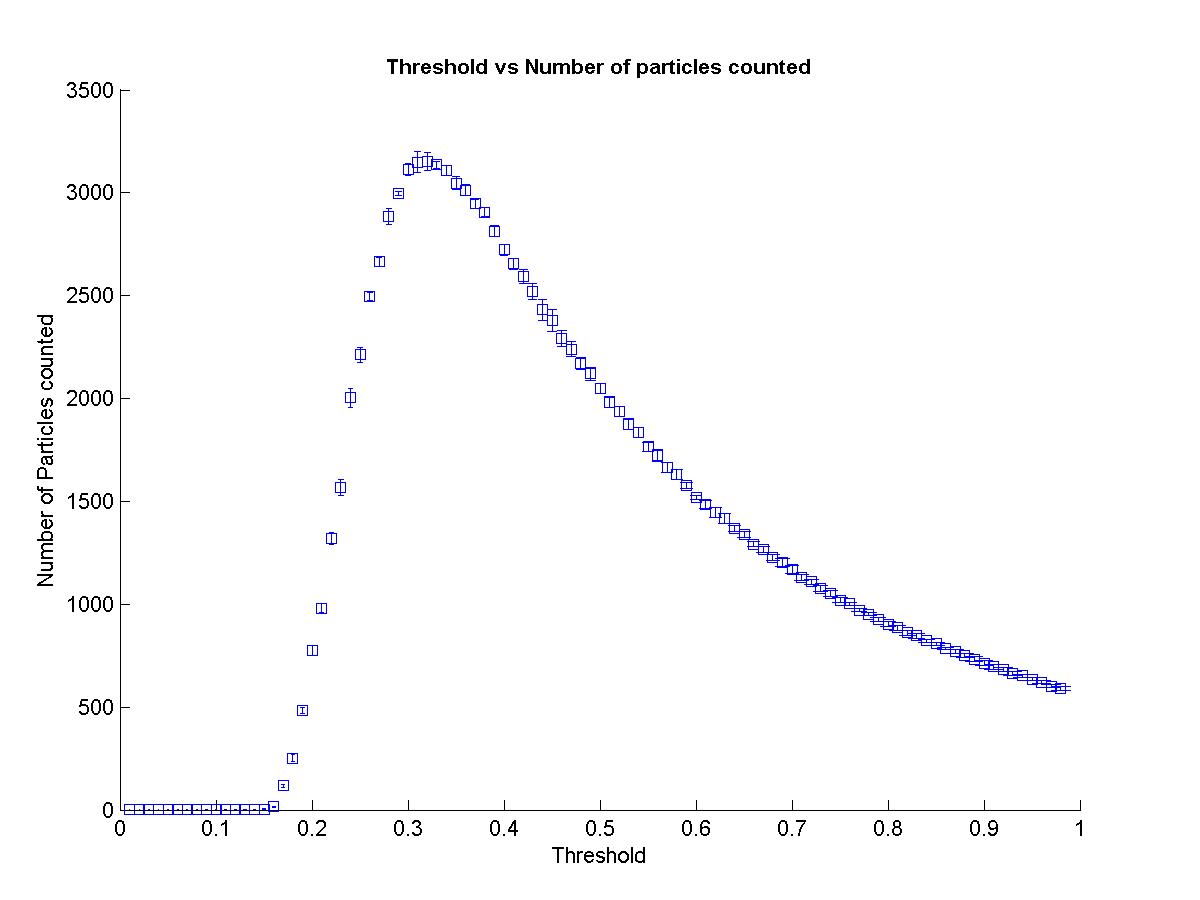

For each concentration and zoom level, the number of particles and average particle size were plotted against intensity threshold values from 0 to 1 (Fig. 3 below). The program was then calibrated to correlate certain concentrations and zoom levels with a corresponding "peak threshold" value and particle count.

Mini Projects

While most of my work is directly related to research, every once in a while I get the opportunity to take on a small pet project for a change in pace. Highlighted below are a few of the novel (albeit useless) things I've made.

3d Gear Box puzzles. An extension of the gear box mini-project in Mec E 260, these gear boxes were built as an exercise to get familiar with the VersaLaser engraver and cutter in the Mec E shop. Design was done completely through SolidWorks, and the finished components were exported as an .SLDDRW file to the cutter for fabrication. Both gearboxes pictured below are assembled entirely without using fasteners or adhesives of any kind. As a result they can be completely disassembled and put back together using only a hex key (to loosen the locating collars on the shafts.)

MATLAB Tic-Tac-Toe. What started as a lunch break project turned into several lunch hours of obsession, culminating in a MATLAB script that allows the user to play tic tac toe against an AI. The computer uses logic checks after every human move to detect win conditions and make moves to either block the opponent or end the game. Also built in is an "AI strategy" function, which evaluates all possible moves based on their probability of resulting in a win for the computer.

MATLAB GIF player. This was the first MATLAB program I wrote to pratice building GUIs (Graphic User Interfaces.) The programs allows the user to play back .GIF files at variables frame rates and click through individual frames of the GIF image. You can also display most static image formats (JPG, PNG, TIFF, BMP, etc.)