PDFs & Technicians Graduates Undergraduates Past Students

Quinn Boser

2nd Year BSc, Mechanical Engineering Biomedical Co-op

Supervisors

Dr. Kajsa Duke, Dr. David S. Nobes, Dr. Jason Carey

Description of Work Term (May - August 2012)

My work term involves the development of a test method for the mechanical testing of custom pelvic fracture fixation plates.

There are two main componets to this project:

- Developing the physical testing set-up

- Developing the data aquisition method

- A preliminary understanding of CCD cameras and their operation

- An understanding of Digital Image Correlation and its many uses

- The ability to use the software DaVis to obtain meaningful engineering information from images of a specimen

- Additional experience with solid modelling, SolidWorks assemblies and assembly and part drawings

- Experience developing a computer program for the control of a Biomechanical Testing Apparatus in National Instruments LabWindows/CVI

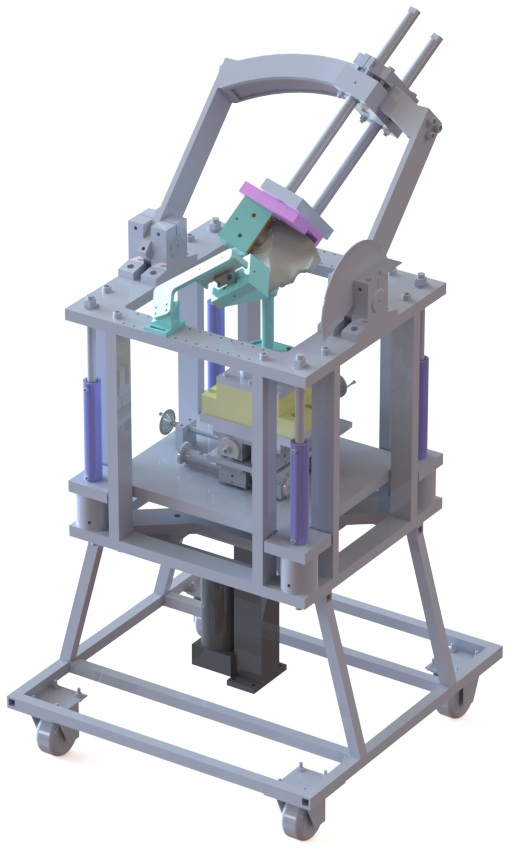

SolidWorks rendered image of the test apparatus

Schematic of MABTA communications

Animated GIF of ParaView surface visualization

Test Apparatus

1. Assemble the apparatus:

The apparatus chosen for the testing was the MABTA (Multi-Axis Biomechanical Testing Apparatus). The MABTA was originally intended for testing cadaveric knee joints. Additional parts had been designed to facilitate fixation and testing of a hemi-pelvis in the MABTA. Once completed, these new parts did not fit together as planned. One of my project goals was to complete the assembly of the apparatus.

My tasks included:

- Finding a commercial part which had been included in the new design and ordering it

- Modifying the design

- Modifying some of the new parts

- Designing a new connecting piece

- Creating SolidWorks drawings for modifications and new part

- Submitting the modifications as a project to the Mec E Shop

- Assembling the apparatus

2. Control the apparatus:

My next goal was to develope a program and user interface for running tests with the MABTA.

There were two devices to communicate with:

- An AMTI 6 DOF Load Cell

- A Kollmorgen Servostart Motor Drive

My tasks included:

- Learning to build user inerfaces and write code in NI LabWindows CVI

- Learning the ASCII commands and acknowledgements for both devices

- Developing a code to convert the binary send from the load cell into load data

- Testing the accuracy of the Load Cell in the Fz (vertical) direction

Data Acquisition and Digital Image Correlation

Definition

Digital Image Correlation (DIC) is an optical method for acquiring deformation and strain information. It involes the use of computer software which tracks the movement of contrast surface features between camera images. Specimens are covered with a random speckle pattern to help the program identify correlation between image sets. For complex objects; multiple camera views help to re-create the object in 3D.

Project Description

My goal this summer was to determine if DIC would be a viable method of data aquisition during the mechanical testing of pelvic fracture fixation plates.

My tasks included:

- Designing and fabricating test specimens similar in size to the visible portion of the hemi-pelvis fixed in the MABTA

- Learning to use a set of CCD cameras with Scheimpflug adaptors

- Learning to use the software DaVis by LaVision to perform DIC on a set of images (DaVis surface creation, DaVis vector processing)

- Testing various speckling methods (Looking for ideal speckle pattern (2-4 pixels))

- Performing tests with known displacements to asess the reliability of DaVis' results

- Post-processing DaVis results using scientific visualization package: ParaView