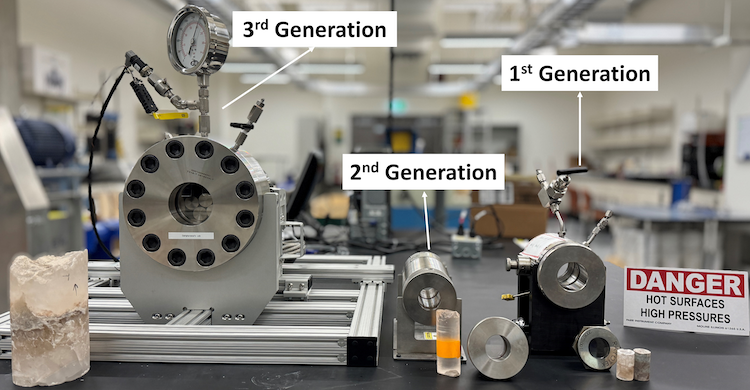

Evolution of Visualization Cell

Introducing our cutting-edge high-pressure, high-temperature visualization cells! These cells operate at up to 6,000 psig and 200°C with various working fluids such as natural gas, hydrocarbon gas, and CO2. In a decade of evolution, now in their third generation, specifically designed for hydrogen injection studies, they are manufactured from 316 stainless steel and accommodate core sizes up to 4 inches in diameter and 12 inches in length.

Perfect for conducting studies on whole cores! With a special data acquisition panel and visualization system, the real-time interactions between the working fluids and rocks are recorded.

.jpg)