Test Facilities - Engine Lab(s) and Project background

Blue Hydrogen-Diesel Dual-Fuel Engine Technology Development

This project explores hydrogen dual-fuel technology as a cost-effective way to reduce carbon emissions in freight transportation by enabling the co-injection of hydrogen and diesel into existing internal combustion engines. Working with a major engine manufacturer, researchers are testing a hydrogen delivery system and control software on a Class 8 diesel engine in a laboratory setting before advancing to field trials. The initiative aims to optimize engine performance while lowering carbon intensity, supporting the transition to a low-carbon economy. Additionally, the project will develop techno-economic assessments, business models, and commercialization strategies.

Hydrogen Technology

Hydrogen is increasingly recognized as a promising alternative to diesel in commercial and heavy freight transportation due to its significant environmental benefits. The goal is to demonstrate the co-injection of clean hydrogen and diesel into a Class 8 diesel internal combustion engine, which will be tested on a full-sized engine in a laboratory environment before field trials are conducted on Alberta roads. The technology can be deployed on any compatible diesel internal combustion engine, offering the ability to retrofit existing vehicles.

Project Goals

This project is dedicated to advancing hydrogen-diesel dual-fuel technology by developing and validating a comprehensive mathematical model to optimize engine performance under diverse operating conditions. A key objective is designing and implementing a hydrogen delivery unit, which will undergo rigorous testing in a pilot demonstration to ensure reliable, steady-state operation.

We are integrating artificial intelligence and machine learning into the engine control unit (ECU) software to enhance efficiency and minimize environmental impact. These technologies will enable real-time performance adjustments, improve emissions characterization, and fine-tune engine operations for optimal fuel efficiency and reduced carbon footprint.

Beyond technical advancements, we are committed to testing the full integrated system, including the hydrogen storage and delivery mechanism, upgraded ECU, and Class 8 diesel engine. This testing phase is critical in demonstrating the feasibility and reliability of hydrogen-diesel co-injection technology.

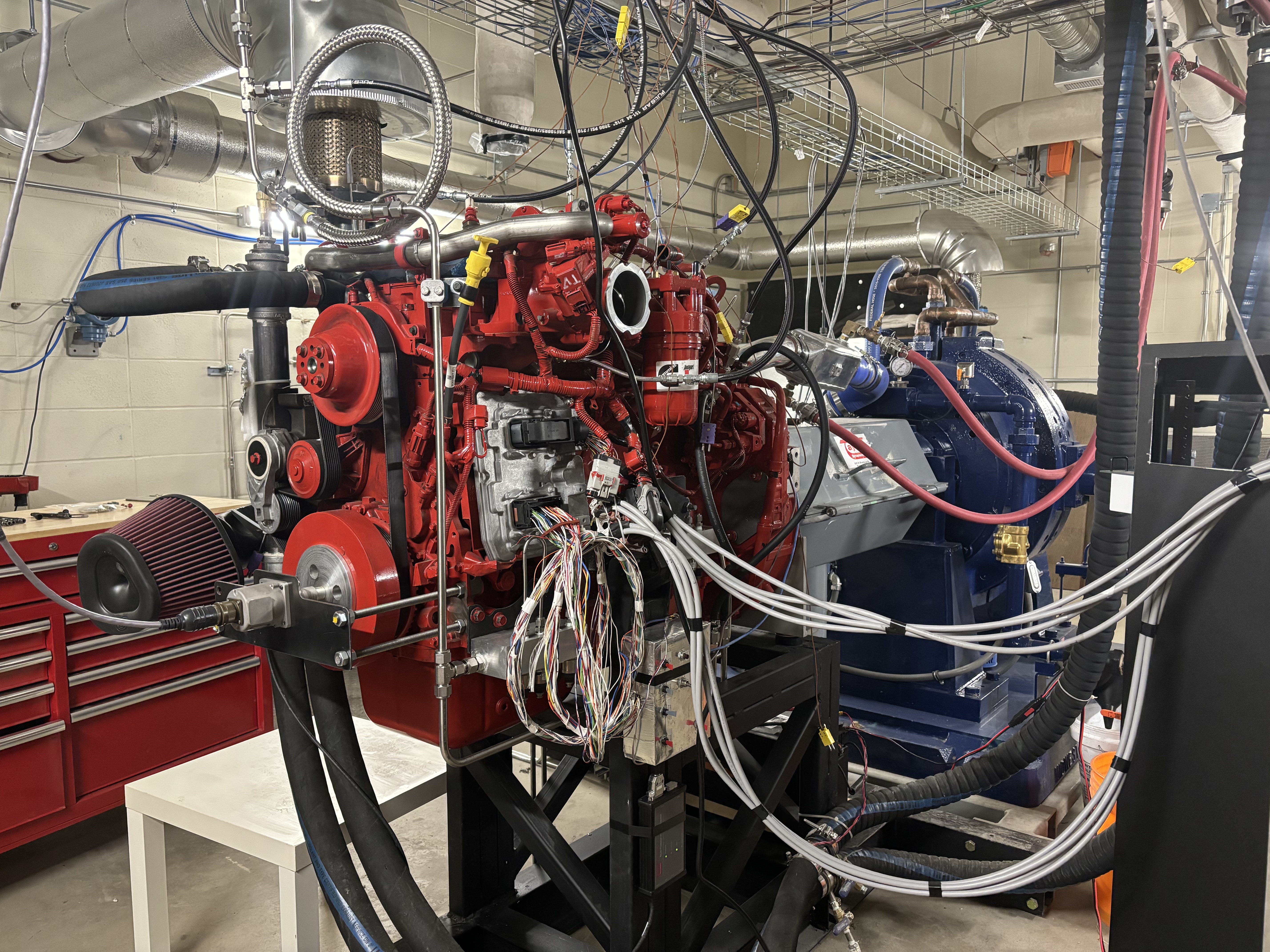

MEECL Heavy Duty Test Cell Capability

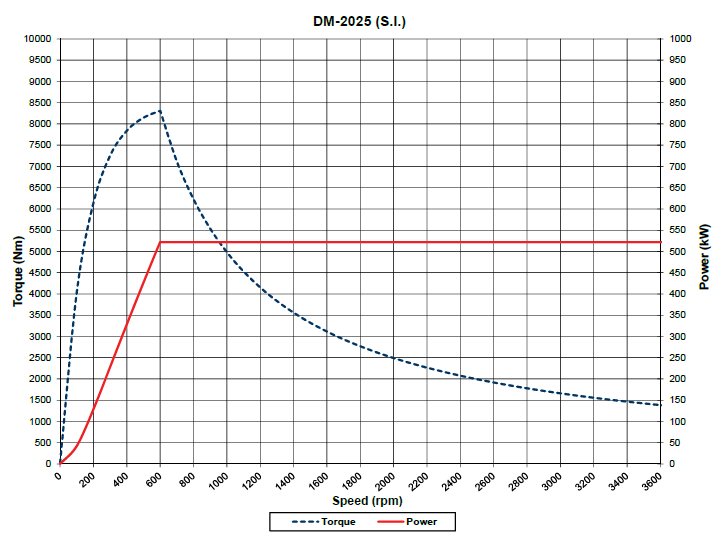

Engine Dyno

- Test cell - off campus

- Taylor DM2055 – 700 hp Engine Dyno for Diesel engine 100-522kW (5-18 liter)

- Dynpro2 (10Hz)

- 16 Temperature sensors K type Thermocouples

- 8 pressure sensors and ambient pressure

- 4 of 0-10 V analog inputs

- 4 of 0-10 V analog outputs to control instruments

- Fully automated test cell in normal and safety alarmed condition

- Fuel flow sensors Emerson Coriolis

- Diesel 1-120 liter/h 0.1% accuracy

- H2 1-40 kg/h 0.1% accuracy

- Fuel

- Diesel fuel 2400l with day tank

- H2 (350bar) 75kg

Emission Measurement Systems

MKS MG2030D FT-IR Spectrometer

- measures most emissions at 5Hz

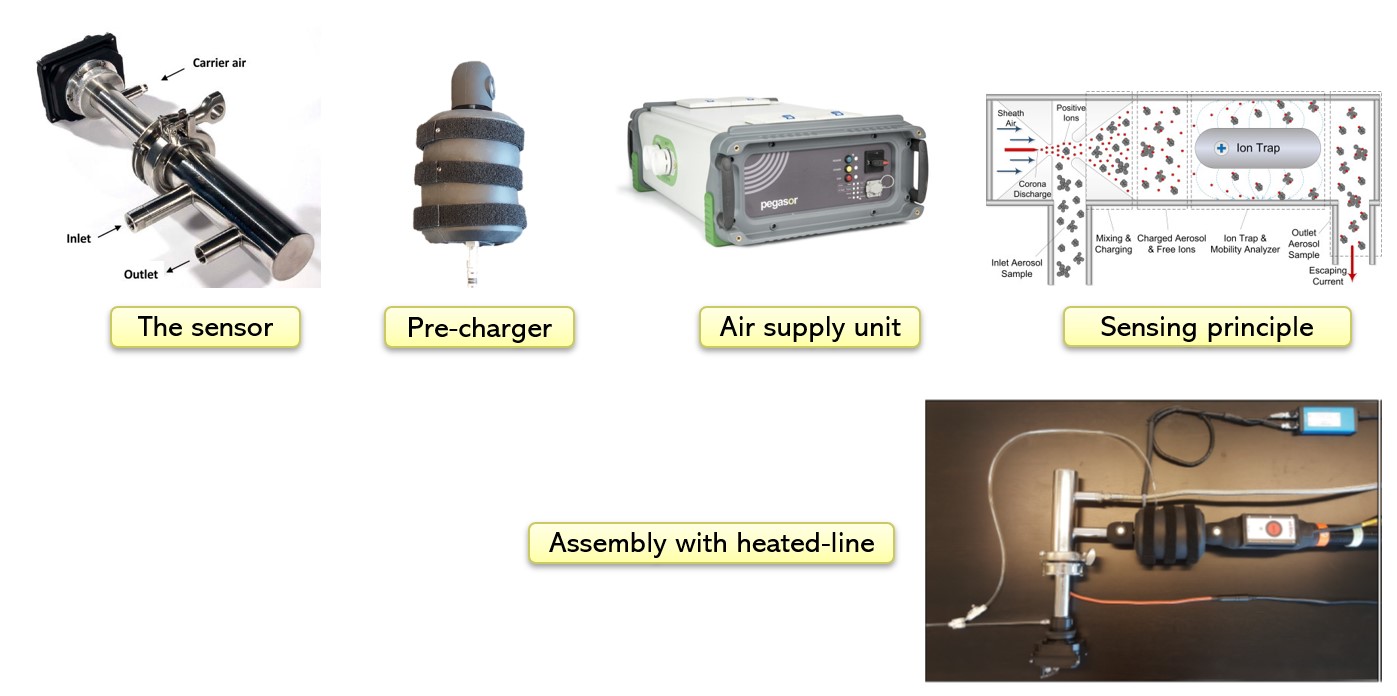

Pegasor PPS-M Soot Measurement

- measures at 5Hz

Production sensors

- NOx measurement (NGK sensor with ECM electronics to CAN Card)

- Lambda Sensor

Kistler Cylinder Pressure and Data Aquisition

- In-cylinder pressure

- Kistler 6054C PiezoStar® Pressure Sensor for Combustion Engines, 300 bar, cable PFA metal braided up to 400 °C, Non-Cooled

- Intake pressure

- Kistler Version 4075: high speed pressure measurement range 0 … 10 bar – calibrated temperature range 15 … 180°C

- Exhaust Pressure

- Kistler Piezo-Resistive Absolute Pressure Sensor 0…10 bar, water-cooled, PiezoSmart, digitally compensated

- Kistler Charge Amplifiers

- 3 X 2-Channel Charge Amplifier Module (BNC Interface), with Drift Compensation for Installation in SCP Slim and KiBox

- National Instruments high speed data acquisition (0.1 degree) or 180kHz at 3000 rpm

- PCIe-6376 Multifunction I/O Device: 8 Simultaneous AI, (16-bit, 3.5MS/s/ch), 2 AO, 24 DIO BNC-2090A Rack-mountable accessory for 68-pin, Multifunction DAQ

Engine Lab - Mechanical Engineering Building

CFR single cylider engine - Wakeshau

single cylinder Ricardo

GM 3.0 Natural Gas Industrial engine

- Digalog AE 150HS dyno

GM 2.0 GDI

Other Equipment

Hot Flow Test rig for soot measurement

NOx test rig

- MKS mass flow controllers

Biojet coflow burner

micro epsilon vibration sensor

Misc

- Sorenson Power supply

- Sorenson Power Supply

Computer Resources

- HP Z840 Desktop Workstation with 2 X Intel Xeon E5-2630 v4 Deca-Core (20-Core) 40 thread with 128Gb Ram

- 2 workstations with 4090GPU's

- use of Compute Canada