Research

Research Interests

Micro- and nanofabrication techniques are presently being utilized to miniaturize a variety of systems, from disease diagnostic systems, to air quality monitoring devices, to airbag accelerometers (to name a few). In micro- and nanofabrication, materials are often selected based on familiarity rather than functionality. For example, many miniaturized devices and systems incorporate silicon, a material made popular by the microelectronics industry. While silicon is very useful in microchips due to its semiconducting properties, it is less useful in devices which require moving parts, such as actuators. For these types of devices, highly deformable materials such as polymers are a more obvious first choice. In the Elias group, research is focused on developing functional polymers (such as smart nanoparticle/polymer composites which can respond to changes in their surroundings), and devising fabrication techniques for patterning these materials on the micro- and nanoscale. Techniques presently being employed include soft-lithography, hot-embossing, and UV-replica molding. The goal of this research is to incorporate functional polymers into microfluidic and other miniaturized devices, with a focus on biomedical applications.

Facilities

Projects in the Elias lab make extensive use of the excellent fabrication and analysis facilities available at the University of Alberta, including the Micromachining and Nanofabrication Facility (NanoFab), and the Alberta Center for Surface Engineering and Science (ACSES). The Elias lab houses a number of pieces of advanced analysis equipment, including a differential photocalorimeter (DSC 1 Mettler Toledo), a Dynamic Mechanical Analyzer (DMA 8000 Perkin Elmer), and a tensile tester (5943 Instron).

Current Research Projects

Stimuli-Responsive Polymers

Stimuli responsive polymers (also called smart materials) which undergo a change in state when exposed to an appropriate stimulus (such as heat, light, or magnetic fields) are of interest for a variety of applications, ranging from wearable devices for personal health monitoring to smart packaging for food freshness and safety. We are presently leveraging the unique properties of nanomaterials to engineer sensors that respond to stimuli including temperature, pH, chemical analytes, and bacteria. We further investigate techniques to pattern these materials on the micro- and nanoscale so as to fabricate sensors. We are particularly interested in printing devices on flexible substrates such as Kapton.

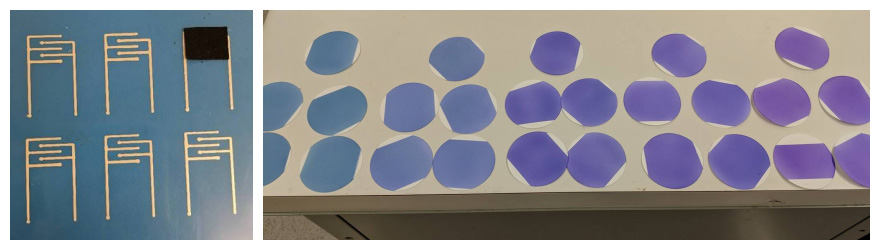

Left: Printed temperature sensors. Right: Spray-coated sensors for detecting food freshness and safety.

Biopolymers for Packaging

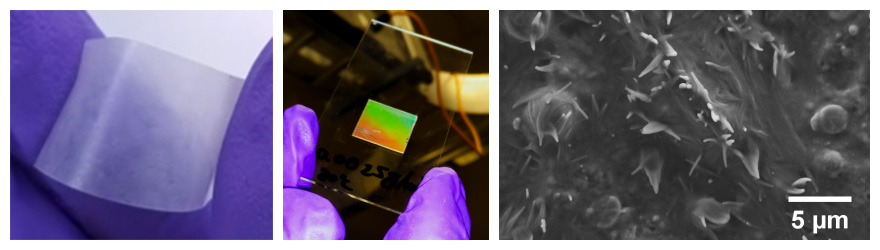

As plastic waste continues to accumulate in the environment, degradable polymers are increasingly being viewed as a viable alternative to conventional plastics. These materials are being considered or implemented for use in biomedical, packaging, and agricultural applications. We are investigating the processing, properties, and enzymatic degradation of biopolymers. These include polyhydroxybutyrate (PHB) a microbially-produced biopolymer that can be degraded by various microorganisms. Degradation can be challenging to measure, particularly for samples with small masses, such as thin films. We therefore developed and validated an optical sensing system for monitoring the degradation of thin films.

Left: Biopolymer film. Center: Diffraction grating for degradation monitoring. Right: Fiber-reinforced polymer.

Microfluidic Fuel Cells

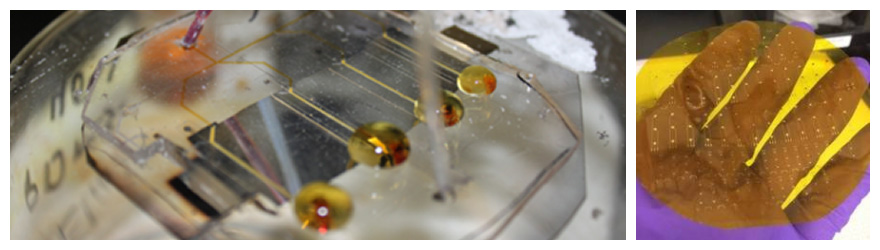

We are developing new methods to fabricate microfluidic fuel cells, which transduce chemical energy into electrical energy. Microscaled devices offer the advantage of high surface area to volume ratios, highly controllable fluidic environments, and parallel testing.

Left: Microfluidic fuel cell. Right: Flexible electronic devices.