J Pharm Pharmaceut Sci

(www.cspscanada.org) 8(3):374-386, 2005

Preparative Enzymatic Synthesis and HPLC Analysis of

Rhapontigenin: Applications to Metabolism, Pharmacokinetics and Anti-Cancer

Studies

Kathryn

A. Roupe1, 2, Greg L. Helms3, 4, Steven C. Halls3, 5,

Jaime A. Yáñez1, 2, Neal M. Davies1,2, 6, 7

1Pharmacology

and Toxicology Graduate Program, 2Department of Pharmaceutical 3Sciences,

Department of Chemistry, 4Center for NMR Spectroscopy, 5Mass Spectrometry

Center,

6Cancer

Prevention and Research Center, 7Center for Integrated

Biotechnology, College of Pharmacy, Washington State University, Pullman,

Washington, USA

Received April 13,

2005; Revised June 14, 2005; Accepted June 28, 2005; Published August 22, 2005

PDF

Version

Corresponding author: Dr. Neal M Davies, College of Pharmacy,

Department of Pharmaceutical Sciences, Washington

State University,

Pullman, Washington,

USA,

99164-6534.

ndavies@wsu.edu

ABSTRACT

Purpose: A facile method was established to enzymatically synthesize

rhapontigenin from the glycosylated parent compound rhaponticin. A novel and

simple high-performance liquid chromatographic method was developed for the

determination of rhapontigenin. The assay was successfully applied to both the in vitro and in vivo metabolic

kinetic study of rhapontigenin. Methods: Serum, or microsomes (0.1 mL) was

precipitated with acetonitrile after addition of the internal standard,

daidzein. Separation was achieved on an amylose tris

3,5 dimethylphenylcarbamate column (150 x 4.6mm, ID, 5μm) with UV

detection at 324nm. Hep G2 hepatoma cells were treated with rhapontigenin or

rhaponticin (0-250 μg/mL) and cell viability was measured. Results:

The calibration curves were linear ranging from 0.5 to 100 mg/mL. The mean

extraction efficiency was > 99%. Precision of the assay (coefficient of

variation) was <5%, including the limit of quantitation (0.5 μg/mL).

Bias of the assay was lower than 5%. The limit of detection was 100 ng/mL for a

0.1 mL sample. One glucuronidated metabolite of rhapontigenin has been identified.

Preliminary pharmacokinetic data revealed the presence of a glucuronidated

metabolite in the serum and a terminal elimination t1/2 of ~6h.

Rhapontigenin demonstrated concentration-dependent anti-cancer activity with an

IC50 115 μg/mL in HEP G2 cells while rhaponticin showed no

activity across the concentrations tested in vitro. Conclusions:

The preparative enzymatic synthesis method has demonstrated utility to

provide sufficient rhapontigenin for pharmaceutical studies. Rhapontigenin is

an active anti-cancer compound. The developed HPLC assay is sensitive,

reproducible and accurate and can be applied to pharmacokinetic and metabolism

studies.

INTRODUCTION

Rhapontigenin, (3, 3’, 5 –trihydroxy-4’-methoxy-stilbene)

C15H16O4, MW: 258 [Table 1], is a stilbene

found in Korean rhubarb rhizomes, and is most abundant in the Rhei undulatum

species [1]. Rhaponticin, the

glycosylated parent compound of rhapontigenin has long been employed in Korea,

Japan, and China as an oral haemostatic agent in treating Oketsu, a disease

characterized by poor circulation, pain, and chronic inflammation [2] [Table

1]. Rhaponticin has also been recommended by health professionals in Asian

countries to treat and prevent allergies [3]. Rhapontigenin, the aglycone of

rhaponticin, has been suggested to be the active molecule [3, 4, 5]. Recent research has shown rhapontigenin to be a

potent anti-allergic, anti-coagulant, and anti-inflammatory compound [6-8].

Rhapontigenin

is structurally similar to the anti-cancer stilbene resveratrol, which is

present in red wine [9]. Considerable scientific studies have demonstrated

potent anti-cancer activity of resveratrol across many cancer cell lines [9].

Given the similarity in structure of resveratrol [Table 1], it is possible that

rhapontigenin also possesses potent anti-cancer activity. Recent investigation

has found rhapontigenin to be a potent inhibitor of the human cytochrome P450

1A1 enzyme, which is implicated in the biotransformation of a number of

carcinogenic and immunotoxic compounds [10].

Additionally, rhapontigenin has been shown to be an inhibitor of CYP

1B1, an enzyme that is expressed and detected in a number of cancers such as

prostate and breast cancers [11].

Although used in traditional Asian

medicine, rhapontigenin has not been thoroughly investigated

pharmaceutically. This is likely due to

the fact that it is not yet commercially available for purchase from chemical

companies. In order to elucidate the metabolism kinetics of rhapontigenin,

knowledge of its metabolic pathways in biological fluids is of considerable

importance. To our knowledge, no study has been published characterizing the in

vitro metabolism of rhapontigenin, and there is no pharmacokinetic

information or validated assays to measure rhapontigenin described in the

literature. Before performing studies of biotransformation, a facile method of

producing pure rhapontigenin is necessary and development of a selective and

sensitive assay for rhapontigenin is needed. The present study describes a

simple method of enzymatic synthesis of rhapontigenin from commercially

available rhaponticin. Furthermore, a selective, isocratic reversed-phase HPLC

method for the determination of rhapontigenin and its metabolites in rat serum

and its application to in vitro and in vivo kinetic studies is detailed.

EXPERIMENTAL

Chemicals and reagents

Daidizen, halothane, rhaponticin, β-glucosidase

from almonds, total protein reagent, protein standard solution, monosodium

glucose-6-phosphate, tetraethylammonium acetate tetrahydrate, b-nicotinamide

adenine dinucleotide phosphate (b-NADP) sodium salt hydrate, and

glucose-6-phosphate dehydrogenase, Trypsin-EDTA, Trypan blue,

phosphate-buffered saline (PBS), resazurin, sodium bicarbonate,

penicillin-streptomycin, and insulin were purchased from Sigma (St. Louis, MO,

USA). HPLC grade methanol, reagent alcohol, acetonitrile, and water were

purchased from J. T. Baker (Phillipsburg,

NJ, USA).

Solid phase extraction (SPE) C-18 columns were purchased from Cayman Chemical

Company (Ann Arbor, MI, USA). Dulbecco’s Modified Eagle Medium (D-MEM) and

RMPI 1640 medium were purchased from Gibco Industries Inc. (Langley, OK, USA). Fetal bovine serum (FBS) was

purchased form Equitech-Bio Inc. (Kerrville,

TX, USA).

Chromatographic system and

conditions

The

HPLC system used was a Shimadzu HPLC (Kyoto, Japan), consisting of an LC-10AT

pump, a SIL-10AF auto injector, a photodiode-array SPD-10A

VP UV/VIS spectrophotometric detector and an SCL-10A system controller.

Injection volume was 150 μL. Data collection and integration were

accomplished using Shimadzu EZ start 7.1.1 program software.

The

analytical column used was an amylose tris 3, 5

dimethylphenylcarbamate (150 ´ 4.6 mm, ID, 5 mm) (Chiral Technologies Inc. Exton, PA, USA). The mobile phase consisted of acetonitrile

and 0.1% phosphoric acid (30:70, v/v), filtered and degassed under reduced

pressure prior to use. Separation was carried out isocratically at ambient

temperature, and a flow rate of 1.0 mL/min, with UV detection at 324 nm.

Mass Spectrometry Conditions

Samples were applied to an API 4000 triple quadrupole

mass spectrometer (Applied Biosystems Sciex, ON, Canada) using negative ion

electrospray under similar chromatographic conditions to those mentioned above

with the exceptions that an Agilent 1100 series HPLC system (Palo Alto, CA,

USA) was employed, consisting of: autosampler, binary pump, degasser, and UV

detector and phosphoric acid was omitted as a modifier while 1 mM (NH4)HCO3

was used to maintain neutral pH.

The mass spectrometer was operated under conditions optimized for

rhapontigenin at the chromatographic flow conditions (0.5 mL min-1)

as follows: The Ionspray needle was

maintained at -4500 kV, with nitrogen as drying gas 1 (setting 40), drying gas

2 (setting 25), curtain gas (setting 10), and collision gas (setting 4). The turbospray interface was maintained at

400 °C. The

declustering potential (DP), collision energy (CE), and exit potential (EP)

were optimum at 30 V, 45 eV and 10 V, respectively. Both the Q1 and Q3 quadrupoles were

maintained at unit resolution (0.7 Da width at half height). The characteristic fragmentation reactions

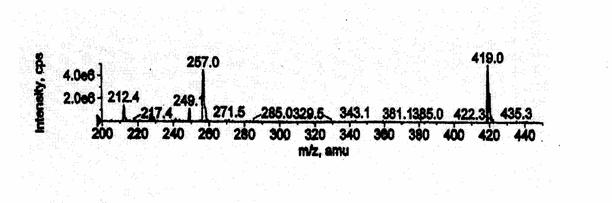

include m/z 257 for rhapontigenin and m/z 419 for rhapontigenin glucuronide.

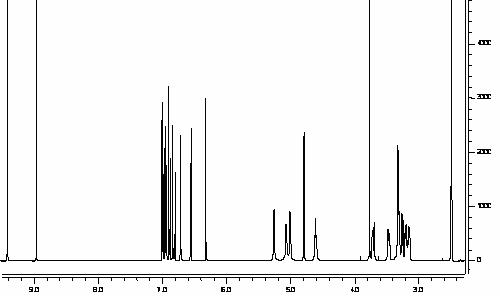

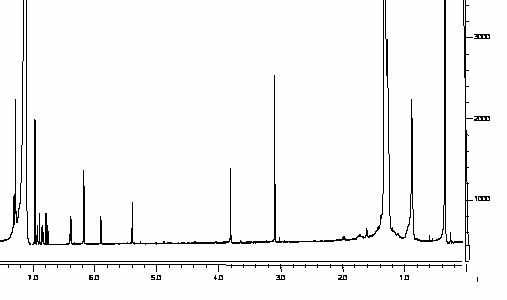

Nuclear Magnetic Resonance (NMR) Conditions

1H NMR (499.85 MHz), 13C NMR

(125.67 MHz) spectroscopic analyses were carried out on a Varian Inova 500 MHz spectrometer. Proton spectra of rhaponticin (6 mg in 700 µl

DMSO-d6) were collected at 22 oC and referenced to the

residual proton signal at 2.49 ppm, whereas the 13C spectra were

referenced to the solvent signal at 39.5 ppm.

Proton spectra of rhapontigenin were obtained in benzene-d6

at 22 oC and were referenced to the residual proton signal at 7.15

ppm. The

phenolic OH protons were in fast exchange with the bulk water in the benzene-d6

solution and hence appear at the bulk water chemical shift which is a 1.35 ppm.

A gradient enhanced phase-sensitive 1H-13C

HSQC spectrum was obtained for rhaponticin using the standard Varian pulse

sequence and was collected with sweep widths (acquisition times) of 4,614 Hz

(222 ms) in t2 (1H) and 16967 Hz (15.1 ms, 256 x 2 hypercomplex

increments) in t1 (13C). The

data were then processed in F2 by applying a Gaussian function with a 0.101 s

time constant prior to Fourier transformation.

The F1 processed data utilized a linear prediction of the original 256

real points to 512 points, apodizing with a Gaussian function using a 0.026 s

time constant, zero filling to 2K complex points and followed by Fourier

transformation. A gradient selected 1H-13C

HMBC was also acquired for rhapontigenin using the standard Varian pulse

sequence and was collected with sweep widths (acquisition times) of 4,614 Hz

(222 ms) in t2 (1H) and 16214 Hz (24.7 ms, 400 increments) in t1 (13C). The data were processed in F2 and F1 by

applying a sine-bell function prior to Fourier transformation. The data in F1 was extended to 800 real

points by linear prediction, zero filled to 4096 points and Fourier

transformed.

Enzymatic Synthesis of Rhapontigenin

A 0.01M tetraethylammonium acetate buffer was made by

adding 261 mg tetraethylammonium acetate to 100 mL HPLC water in a volumetric

flask. The pH was adjusted to 5.0 using 1M HCL. 4 mL buffer was filtered and

added to a clean glass test tube. 20 mg rhaponticin was weighed carefully and

added to the prepared buffer. The rhaponticin solution was sonicated and

vortexed until dissolved. The rhaponticin solution was then placed in a 37 oC

shaking water bath. Next, an enzyme solution was prepared by adding 1 mL buffer

to 6 mg β-glucosidase. The enzyme solution was shaken gently and directly

added to the rhaponticin solution. The resulting solution was incubated for 72

hours. 200 μL aliquots of the incubate were taken every 24 hours and the

reaction progression was monitored via HPLC [Figure 1].

The

final incubate was transferred to a solid phase extraction C-18 column and the

eluted solution was collected in a test tube. The SPE column was washed with

HPLC water and the aqueous fraction was collected in a separate test tube.

Finally, the SPE column was eluted with 2 mL methanol and the methanol fraction

was collected in a glass test tube and dried under a gentle stream of nitrogen

gas. The resulting powder was weighed, transferred to a screw top glass vial

and stored at 4oC. The

successful enzymatic synthesis of rhapontigenin was verified by NMR and mass

spectrometry with an m/z ratio of 256.6 and a fragmentation pattern

consistent with rhapontigenin [Table 2-3

Figures 2-4].

Figure 1:. HPLC-monitored enzymatic reaction of

rhaponticin into rhapontigenin via β-glucosidase.

The melting point of the newly synthesized rhapontigenin

was determined employing a Thomas Hoover Capillary Melting Point Apparatus®

(Arthur H. Thomas Company, Philadelphia,

PA, USA).

The heat setting was set at 3.9 and the temperature was ramped at 1.0 oC/

minute. Visual determination of the melting point showed the uncorrected onset

temperature to be 182.0 oC and the end point to be 184.0 oC.

Stock and

Working Standard Solutions

Methanolic stock solutions of

rhapontigenin (1 mg/mL) and daidzein (1 mg/mL) were prepared. The daidzein

solution was subsequently diluted with methanol to make a working internal

standard (IS) solution of 10 µg/mL. These solutions were protected from light

and stored at -20 °C between uses, for no

longer than 3 months. Calibration standards in serum were prepared daily from

the stock solution of rhapontigenin by sequential dilution with blank rat

serum, yielding a series of concentrations namely 0.5, 1.0, 5.0, 10.0, 50.0,

100.0 mg/mL), in four replicates.

|

Table 2: H’NMR values for Rhapontigenin:

(Benzene-d6)

|

|

OH

|

Exchanging with Benzene-d6

|

|

H2

|

6.18

|

|

H4

|

5.40

|

|

H6

|

6.18

|

|

Hα

|

6.77

|

|

Hβ

|

6.90

|

|

H2’

|

6.85

|

|

H3’

|

6.39

|

|

OCH3’

|

3.10

|

|

H6’

|

5.91

|

Quality

control (QC) samples were prepared from the stock solution of rhapontigenin by

dilution with blank rat serum to yield target concentrations of 0.5, 1.0, 5.0,

10.0, 50.0 and 100.0 µg/mL. The QC samples were divided into 0.5 mL aliquots in

screw-capped test tubes and stored at -20 °C before use.

Sample preparation

0.1 mL of internal standard solution (10 µg/mL) was

added to working standards or samples (0.1 mL). The mixture was precipitated

with 1.0 mL ice-cold acetonitrile and was centrifuged at 8,000 x g for 5 min

using Beckman microfuge. Following

transfer of the supernatant to new vials, the residue was placed in sample

vials 150 µL of the supernatant was injected onto the column.

Precision and accuracy

The within-run precision and accuracy of the replicate

assays (n=6) were tested by using six

different concentrations, namely 0.5, 1, 5, 10, 50 and 100 mg/mL. The

between-run precision and accuracy of the assays were estimated from the

results of six replicate assays of QC samples of six different days within one

week. The precision was evaluated by calculating the coefficient of variation

(CV) using ANOVA. The accuracy was estimated based on the mean percentage error

of measured concentration to the actual concentration. The values of CV and

bias were within 15%, at all concentrations tested [12].

Recovery

Recovery of rhapontigenin from rat serum was assessed

(n=6) at 0.5, 1.0, 5, 10, 50, 100 mg/mL. A known amount of rhapontigenin was

spiked into 0.1 mL rat serum to give the above concentrations. The proteins

present in the serum were precipitated with 1mL ice-cold acetonitrile and the

supernatant was analysed by HPLC following centrifugation at 8,000 x g for 5

min. The extraction efficiency was

determin ed by comparing the peak area ratio (PAR)

of rhapontigenin to IS in the serum matrix to that in water.

Stability of Rhapontigenin

Samples

The stability of rhapontigenin samples were assessed

under five different conditions. The stability of rhapontigenin in rat serum at

room temperature (22 ± 1 ºC) and at –20 ºC was investigated using

QC samples of five concentration levels, 1, 5, 10 mg/mL in four replicates.

The

freeze-thaw stability of rhapontigenin was evaluated at three concentrations 1,

5, and 10 mg/mL, using QC samples. These samples

were analyzed in

triplicate without freezing, and then stored at –20

°C and thawed at room temperature (22

± 1 ºC) for

three cycles.

Table

3: 1H’NMR and 13C’NMR

for Rhaponticin: (DMSO-d6)

|

C1

|

138.99

|

|

|

|

C2

|

100.52

|

H2

|

4.79

|

|

C3

|

158.67

|

|

|

|

C4

|

102.77

|

H4

|

6.33

|

|

C5

|

158.14

|

OH5

|

9.44

|

|

C6

|

107.12

|

H6

|

6.57

|

|

Cα

|

125.93

|

Hα

|

6.83

|

|

Cβ

|

128.29

|

Hβ

|

6.98

|

|

C1’

|

129.83

|

|

|

|

C2’

|

112.83

|

H2’

|

7.01

|

|

C3’

|

146.39

|

3’-OH

|

8.97

|

|

C4’

|

147.54

|

|

|

|

4’-OCH3

|

55.59

|

4’-OCH3

|

3.77

|

|

C5’

|

111.95

|

H5’

|

6.89

|

|

C6’

|

118.43

|

H6’

|

6.95

|

|

Glucose Ring

Assignments:

|

|

|

C1’’

|

100.50

|

H1’’

|

4.79

|

|

C2’’

|

73.21

|

H2’’

|

3.19 2’’-OH

5.26

|

|

C3’’

|

76.62

|

H3’’

|

3.25 3’’-OH

5.07

|

|

C4’’

|

69.69

|

H4’’

|

3.14 4’’-OH

5.01

|

|

C5’’

|

77.04

|

H5’’

|

3.30

|

|

C6’’

|

60.65

|

H6’’a

|

3.46 H6’’b

3.70 6’’-OH 4.61

|

The

stability of rhapontigenin in reconstituted extracts during run-time in the

HPLC auto-injector was investigated, using pooled extracts from QC samples of

three concentration levels, 1, 5, 10 mg/mL.

Samples were kept in the sample rack of the auto-injector and injected

into HPLC system every 6h, from 0 - 24 h, at the temperature of auto-injector

(26 ± 1 °C).

The

stability of reconstituted extracts was also tested at –20 °C for one week. The reconstituted extracts of six

concentrations, 0.5, 1, 5, 10, 50 and 100 mg/mL were allocated in injection vials,

stored at –20 °C and injected onto the column on day 0 and day 1.

The

stability of reconstituted extracts was also tested at –20 °C for one

day. The reconstituted extracts of six

concentrations, 0.5, 1, 5, 10, 50 and 100 mg/mL were allocated in injection vials,

stored at –20 °C and injected onto the column on day 0 and day 1.

The

light stability of rhapontigenin in stock solution was also tested at room

temperature for one day. Samples were exposed to laboratory (fluorescent

overhead) illumination for up to 24 hours and injected onto the column from

time 0 to 24 h post illumination.

Stability of Rhapontigenin in

Rat Serum

Rhapontigenin was incubated in rat serum at 37.0 ± 0.1 °C in a

thermostatically controlled shaking water bath. Prior to the kinetic study, the

incubation media were equilibrated to the temperature of the study. Kinetic

studies were initiated by the addition of a stock solution of rhapontigenin to

incubation media, yielding an initial concentration of 10 mg/mL. At

pre-determined time intervals, samples (0.5 mL) were removed and the reaction

was stopped by adding equal volume of ice-cold acetonitrile and mixing immediately.

Samples were analysed by HPLC following centrifugation at 8,000x g for 5 min

using Beckman microfuge.

Pharmacokinetics

Male Sprague Dawley rats (n=3, 300-325 g, Harlan, Indianapolis, IN,

USA) were

anaesthetized using halothane and a silastic catheter was cannulated into the

right jugular vein. The animals were

placed in metabolic cages, allowed to recover overnight and fasted for 12 h

before dosing. On the day of experiment, the animals were dosed intravenously

with an IV dosing solution of rhapontigenin (10 mg/kg) in 5% dimethyl sulfoxide

(DMSO) and polyethylene glycol 400 (PEG-400). Serial blood samples (0.25 mL)

were collected at 0, 1 min, 10 min, 0.25, 0.5, 1, 2, 4, 6, 12 and 24 h. After

each sample collection, the cannulas were flushed with 0.25 mL of saline.

Following centrifugation of the blood samples, serum was collected and stored

at –70 °C until analysed. The experimental animal protocols

were approved by the Institutional Animal Care and Use Committee of Washington

State University.

Rat Liver Microsomes Preparation

Male rat liver microsomes were prepared from adult

male Sprague-Dawley rats using previously published procedures [13,14]. The

fresh rat livers were cut from euthanized rats and put into ice-cold

saline, weighed, and minced. Samples were homogenized using a motorized

homogenizer (four strokes) in ice-cold homogenization buffer

(50 mM pH 7.4 potassium phosphate buffer, 250 mM sucrose, 1 mM

EDTA) and centrifuged at 7700 x g for 15 min at 4 °C. The

supernatant collected was then centrifuged again at 18,500 x g

for 15 min at 4 °C. After the pellet was discarded, the

supernatant was centrifuged again at 85,600 x g for

1.0 h at 4 °C to yield microsome pellets. The microsomes were

resuspended in microsome washing buffer (10 mM pH 7.4 potassium

phosphate buffer, 0.1 mM EDTA, and 150 mM KCl) and

centrifuged again at 85,600 x g for 1.0 h at 4 °C to yield microsomes.

The microsome pellet was then resuspended in 250 mM sucrose,

aliquoted into vials (0.5 mL/vial), and stored at -80 °C until

use.

Microsome Protein Concentration

Protein concentration of microsomal protein was

determined using a protein assay (Bio-Rad, Hercules, CA, USA), using bovine serum albumin

as standard.

Phase I Metabolism

Studies of metabolic kinetics of rhapontigenin were

conducted in the presence of cofactors which included 10 mM MgCl2

and an NADPH-generating system (7.5 mM glucose 6-phosphate, 0.3 mM b-NADP and 0.42

unit/mL glucose-6-phosphate dehydrogenase), in 100 mM phosphate buffer

containing 1 mM EDTA (pH 7.4) under carbogen gas at 37.0 ± 0.1 °C in a shaking

(75 rpm) water bath. The parent drug was added as a methanolic stock solution

of 1.0 mg/mL (at a volume of 0.5% in the final incubation mixtures) and was

pre-incubated in the incubation buffer for 5 min at 37 ± 0.1 °C. The reaction was initiated by adding the

cofactors. At pre-determined time intervals, samples (0.5 mL each) were

withdrawn and the reaction was terminated immediately by adding 50 µL of

94% acetonitrile/ 6% glacial acetic acid. Samples were then

extracted and analysed by HPLC.

Phase II Metabolism

The incubation procedures for measuring uridine

diphosphate-glucuronosyltransferase (UGT) activities using microsomes were as

follows: 1) Microsome (final concentration ~0.05 mg protein/ml) was

mixed with each of the following: MgCl2 (0.88 mM),

saccharolactone (4.4 mM), and alamethicin (0.022 mg/ml).

42 μM of rhapontigenin in a 50 mM potassium phosphate

buffer (pH 7.4) was added as the substrate and finally uridine

diphosphoglucuronic acid (3.5 mM) was added to activate the reaction. 2)

The mixture was incubated at 37 °C for 10, 20, 30, or 60 min; and 3). The

reaction was stopped by the addition of 50 µL of 94% acetonitrile/6%

glacial acetic acid.

Cell Culture

Hep-G2 (human hepatoma) cell line was obtained from

the American Type Culture Association (ATCC, Rockville, MD.)

and maintained in Dulbecco’s Modified Eagle Medium (D-MEM). The Cell line was

supplemented with 10% heat-inactivated fetal bovine serum (FBS),

penicillin-streptomycin (10mg/1L) insulin (4mg/mL) and was incubated at 37oC

in a 5% CO2 atmosphere.

Cell Number

The optimal cell seeding numbers for each cell line

was determined by preliminary cell seeding number experiments. Cells were

seeded in numbers 1 x 104, 2 x 104, 3 x 104

and so on until the final cell seeding number 1 x 105 per well in a

96 well plate (Costar 3595). Cell plates were incubated at 37oC in a

5% CO2 atmosphere for 72 hours. Following incubation, medium was

aspirated and alamar blue (resazurin) fluorescent dye solution was diluted in

fresh medium to make a 10% resazurin solution. The 10% solution was added

directly to cells. The cell plates were incubated at 37oC in a 5% CO2

atmosphere for 3 hours. The cell plates were subsequently removed from the

incubator and placed at room temperature in a darkened drawer to protect from

light for 30 minutes. Next, the cell plates were placed into the Cytoflour®4000

fluorescence multi-well plate reader (Applied Biosystems, USA).

Fluorescence was read at an excitation of 485 nm and an emission of 530 nm.

Standard curves of cell seeding number against fluorescence were generated. Hep

G2 cells were seeded at a density of 5000 cells/well.

Alamar Blue Assay

Alamar Blue (resazurin) fluorescent dye is a facile

and accurate assay that has recently gained scientific popularity in

determining the cytotoxicity of many cell lines [15]. The resazurin

non-fluorescent compound is metabolised into the fluorescent compound resorufin

by intact and viable cells. This

emission of fluorescence can be quantified using a cell plate reader and the

number of viable cells following treatment can be determined. Cells were

counted and seeded on 96 well plates. The seeded cells were incubated at

37oC in a 5% CO2 atmosphere for 24 hours. Rhaponticin and

rhapontigenin were dissolved in methanol the day of the experiment and were

diluted in medium to yield concentrations of 0.1, 1, 10, 50, and 100 μg/mL. Following aspiration of the medium, cells

were treated with the stilbene solutions. Additional cells were treated with

either methanol diluted in medium or medium only. Treated and control cells

were incubated at 37oC in a 5% CO2 atmosphere for 72 hours.

After cell plates were removed from the incubator, medium was aspirated and

replaced with 10% alamar blue (resazurin) fluorescent dye diluted in fresh

medium. Cell plates were incubated at 37oC in a 5% CO2

atmosphere for an additional 3 hours. Following incubation, cell plates were

placed in a darkened environment for 30 minutes at room temperature. Next, the

cell plates were placed into the Cytoflour®4000 fluorescence multi-well plate

reader (Applied Biosystems, USA).

Fluorescence was read at an excitation of 485 nm and an emission of 530 nm. The

viable cell number (as a percent of control) in each cell line exposed to

varying concentrations of stilbene was measured.

Data analysis

Rhapontigenin was identified with and without

β-glucuronidase by its retention time relative to the internal standard

(IS) on HPLC chromatograms. Quantification was based on calibration curves

constructed using the peak area ratio (PAR) of rhapontigenin to (IS), against

rhapontigenin concentrations using unweighted least squares linear regression.

The percentage of metabolism products was estimated as the ratio of PAR of

metabolite to PAR of patent drug at time zero. The apparent decomposition rate

constants (kapp) were

estimated from the slope of log-linear phase of declining concentration versus

time plots. The half-lives (t½)

were calculated using the following equation: t½ = 0.693/ kapp.

Data were expressed as the mean ± standard deviation (SD) of replicate

determinations. Pharmacokinetic parameters were estimated using WinNonlin®

(version 1.0).

RESULTS

Chromatography

There were no interfering peaks co-eluted with the compounds

of interest (Figure 5). Separation of rhapontigenin and the internal standard

in rat serum were achieved successfully. The retention times of rhapontigenin

and IS were approximately 22 min and 16 minutes, respectively (Figure 6).

The performance of the HPLC assay was

assessed using the following parameters, namely peak shape and purity,

interference from endogenous substances in rat serum, linearity, limit of

quantitation (LOQ), limit of detection (LOD), freeze-thaw stability, stability

of reconstituted extracts, precision, accuracy and recovery. Various conditions

of HPLC were tested to achieve the best resolution of rhapontigenin. The retention

times of analytes were found to be very sensitive to the percentage of

acetonitrile in the mobile phase. The optimal separation was achieved when the

combination of acetonitrile and phosphoric acid was 30:70 (v/v) and the flow

rate was 1.0 ml/min.

Based

on spectrophotometer analysis of rhapontigenin reconstituted in mobile phase

prior to HPLC analysis, UV detection was set at 324 nm.

Linearity, LOQ and LOD

An excellent linear relationship (r2 = 0.998) was demonstrated

between peak area ratio (PAR) of rhapontigenin to IS and the corresponding

serum concentrations of rhapontigenin over a range of 0.5 to 100 mg/mL.

Figure 5: Blank rat serum demonstrating no

interfering peaks co-eluted with the compounds of interest.

Figure 6: Rat

serum containing daidzein (internal standard) and rhapontigenin with at a

concentration of 10 mg/mL.

The

mean regression line from the validation runs was described by rhapontigenin mg/mL= Peak

area ratio x 1.4366+2.2237. The LOQ of this assay was 0.5 mg/mL in rat

serum with the corresponding relative standard deviation and bias of 0.83 and

8.8%, respectively. This calibration curve was cross-validated with QC samples

of rhapontigenin in microsomes. The back-calculated concentration of QC samples

in these matrices was within the acceptance criteria. The LOD of rhapontigenin

was estimated to be 0.1 mg/mL in rat.

Precision, Accuracy and

Recovery

The within- and between-run CV calculated during

replicate assays (n=6) of

rhapontigenin in rat serum were <5% over a wide range of rhapontigenin

concentrations. The intra- and inter-run bias assessed during replicate assays

varied between –4.7 and 14.6%. Precision

and accuracy studies indicated that the developed HPLC method is reproducible

and accurate. The mean extraction efficiency for rhapontigenin from rat serum

varied from 99 to 100.2%. High recovery of rhapontigenin from rat serum

suggested that there was negligible loss during the protein precipitation

process, and the efficiencies of extraction of rhapontigenin and IS were

comparable.

Stability of Rhapontigenin

Samples

No significant degradation was detected after the

samples of rhapontigenin in rat serum were stored at room temperature for 3 h,

or in a freezer at or below –20 °C for 4 weeks, or after undergoing one

freeze-thaw cycle. Under ambient conditions for 3 h, there was > 99% of

rhapontigenin recovered across concentrations. When stored in a freezer at –20 °C, recoveries

of rhapontigenin were >99% after 1 and 4 weeks. The recoveries were >95%

following three freeze-thaw cycles in all concentrations tested (1 μg/mL,

5 μg/mL, and 10 μg/mL). There

was no significant decomposition observed after the reconstituted extracts of

rhapontigenin were stored in the auto-injector at room temperature for 24 h or

in freezer at –20 °C for 1 week. The measurements were >99% of the

initial values for all concentrations during the storage in the auto injector

at room temperature for 24 h. When

stored in a freezer at –20 °C, the recovery was >99% within one week

at all concentrations investigated.

Metabolism of Rhapontigenin in

Rat Liver Microsomes under a NADPH Generating System

The HPLC method has been applied to the determination

of rhapontigenin and its metabolic products in the Phase I metabolic kinetic

study of rhapontigenin in rat liver microsomes.

Rhapontigenin was added individually to microsomes in a concentration of

10 mg/mL. Following the incubation of rhapontigenin as

parent

drug at 37 °C in rat liver

microsomes with an NADPH generating system, no observable peaks were detected

and no decrease in parent rhapontigenin was evident, suggesting no appreciative

oxidative metabolism is apparent.

Pharmacokinetics of Rhapontigenin in Rats

The HPLC method has been applied to the determination

of rhapontigenin in pharmacokinetic studies in rats. There are no previously

published studies or information of the pharmacokinetics of rhapontigenin in

any species. Following administration of rhapontigenin there was an apparent

terminal elimination half-life of ~6h for the parent compound [Figure 7].

Figure 7: Mean

intravenous pharmacokinetics of rhapontigenin in male Sprague Dawley rats (n=3).

One

previously unidentified metabolite was detected with a retention time of 4

minutes in the solvent front. The metabolite was measured indirectly by

treating samples with β-glucuronidase and measuring the increase in parent

compound. The metabolite was isolated and the m/z ratio and fragmentation pattern was determined using mass

spectrometry. The metabolite was shown to have an m/z ratio of

419 and a fragmentation pattern that is consistent with glucuronidation [Figure

8]. The pharmacokinetics of rhapontigenin appears to be qualitatively very

similar to previous reports of resveratrol in the rat where a glucuronide

metabolite is also present in plasma [19].

Metabolism of Rhapontigenin in

Rat Liver Microsomes under a UGT Generating System

The HPLC method has been applied to the determination

of rhapontigenin and its metabolic products in the phase II metabolic kinetic

study of rhapontigenin in rat liver microsomes.

Rhapontigenin was added individually to microsomes in a concentration of

10 mg/mL. Following the incubation of rhapontigenin as

parent drug at 37 °C in rat liver microsomes with the UGT enzyme, a rapid

and significant decrease in rhapontigenin was detected. A metabolic peak was

observed, eluting at 4 minutes, which could not be resolved from the solvent

front. The amount of this metabolite detected increased over time coinciding

with the reduction of parent rhapontigenin [Figure 9].

This suggests that extensive glucuronidative

metabolism is apparent, which was confirmed by mass spectrometry analysis. The

glucuronidated metabolite had an m/z ratio of 419 and a fragmentation

pattern consistent with glucuronidation. Due to the fact that the metabolite

eluted with the solvent front, the quantification

of metabolite was determined indirectly

using β-glucuronidase to hydrolyze the metabolite

back to

parent compound. This technique has been extensively

used in metabolism and pharmacokinetic research to determine metabolite

concentration over time [16, 17, 18].

β-glucuronidase was added to a set of microsomal samples instead of

acetic acid/acetonitrile stop solution. These samples were analyzed via HPLC

along side of original microsomal samples exposed to the stop solution. HPLC

analysis confirmed the absence of the glucuronidated metabolite. This same peak

at the same retention time was also apparent in the rat serum

Figure 9: Phase II

Microsomal metabolism of Rhapontigenin in rat liver microsome.

.

Anti-cancer Activity of Rhaponticin and Rhapontigenin

in Hep-G2 Cells.

The anti-cancer activities of rhaponticin and

rhapontigenin were tested in the Hep-G2 hepatoma cell line. Analysis of cell

viability as a percent of the control following exposure showed greater

activity in cells treated with rhapontigenin compared to the parent compound

rhaponticin. At the highest concentration tested (250 μg/mL), the viable

number of cells detected was 10% of that of the control. Comparatively,

rhaponticin showed little pharmacological activity [Figure 10]. The IC50

of rhapontigenin in the Hep-G2 cell line was determined by pharmacodynamic

modeling using WinNonlin® (version 1.0) and was determined to be 115.0±49.3 μg/mL.

DISCUSSION

Rhapontigenin is a stilbenoid compound that has been

shown to be an active anti-allergenic, anti-inflammatory and anti-cancer agent.

Recent investigation has found rhapontigenin to be a potent inhibitor of human

cytochrome P450 1A1 enzyme. This enzyme is implicated in the biotransformation

of a number of carcinogenic and immunotoxic compounds. In addition to potently

inhibiting P450 1A1, rhapontigenin is also an inhibitor of CYP 1B1. This enzyme

is expressed and detected in a number of cancers such as prostate and breast

cancers. These data demonstrating the

possible anti-cancer activity of rhapontigenin illustrates the necessity for

further characterization, testing, and development of this compound. However,

rhapontigenin is not commercially available and a facile method for its

synthesis is imperative in order to develop an assay for its quantification as

well as to further study its pharmacological properties. This current research describes a novel method

for the enzymatic synthesis of rhapontigenin from its glycosylated parent

compound rhaponticin. Moreover, the development and validation of this HPLC

assay methodology is described and its applicability to the study of

pharmacokinetics, metabolism and anti-cancer activity of rhapontigenin has been

demonstrated.

Our metabolism data shows that rhapontigenin is

extensively glucuronidated. This same pattern of metabolism has been

demonstrated for other structurally similar stilbene compounds namely

piceatannol, pinosylvin, and resveratrol [Table 1] [16-19] in which the

glucuronidated metabolite is extensive and present in both in vivo male

rat serum samples and in in vitro male rat liver microsomal fractions.

In addition, the preliminary pharmacokinetic characterization of rhapontigenin

appears to be very similar to those of piceatannol, pinosylvin, and

resveratrol.

Figure 10: Anti-cancer activity of Rhaponticin and

Rhapontigenin in Hep-G2 cells.

Our data from the

alamar blue assay, which measured Hep G2 hepatoma cell viability following treatment

with rhapontigenin and rhaponticin, demonstrated that rhapontigenin possesses anti-cancer

activity with an IC50 115.0±49.3 μg/mL. Comparatively,

rhaponticin showed insignificant activity. This data further supports the

concept that rhapontigenin is the active molecule compared to its glycosylated

parent compound, rhaponticin, and that rhaponticin must be biotransformed into

rhapontigenin to elicit anti-cancer activity.

CONCLUSIONS

In summary, the developed enzymatic synthesis method

for rhapontigenin is facile and facilitates preparative rhapontigenin

production and may have utility for preparation and purification of other stilbene

and flavonoid glycosylates to be resolved into their respective aglycones. The

developed HPLC assay is sensitive, reproducible, accurate and specific. It has

been successfully applied to the preliminary study of pharmacokinetics and

metabolism of rhapontigenin in rats and is the first report of these

pharmacometric properties in any species. Using this HPLC method, large numbers

of biological samples can be analyzed in a relatively short period of time.

Further studies are ongoing in our laboratory to further characterize the

pharmacokinetics and metabolites of rhapontigenin and other stilbenes as well

as their pharmacological and toxicological activities.

ACKNOWLEDGEMENTS

The authors would like to thank the Monroe Mullen

Fellowship awarded to KAR, Dr. Rob Ronald for helping to determine the melting

point of rhapontigenin, and a grant from the Organic Center

for Education and Promotion to NMD.

REFERENCES

- Ko SW, Lee

SM, Whang WK. Anti-platelet aggregation activity on stilbene derivatives from Rheum

undulatum. Arch Pharm Res, 22:401-403, 1999.

- Matsuda H,

Kageura T, Morikawa T, Toguchida I, Harima S, Yoshikawa M. Effects of stilbene constituents from

rhubarb on nitric oxide production in lipopolysaccharide-activated

macrophages. Bioorg Med Chem Lett, 10:323-327, 2000.

- Matsuda H,

Tomohiro N, Harima K, Harmina S, Ko S, Matsuo K, Yoshikawa M., Kubo M.

Study on anti-Oketsu activity on rhubarb II. Anti-allergic effects of

stilbene components from Rhei undulati Rhizoma (dried rhizome of Rheum

undulatum cultivated in Korea). Biol Pharm

Bull, 24:264-267, 2001.

- Kageura T,

Matsuda H, Morikawa T, Toguchida I, Harima S, Oda M, Yoshikawa M.

Inhibitors from rhubarb on lipopolysaccharide-induced nitric oxide

production in macrophages: structural requirements of stilbenes for the

activity. Bioorg Med Chem, 9:1887-1893, 2001.

- Park

EK, Choo MK, Yoon HK, Kim DH. Antithrombotic and anti-allergic activities

of rhaponticin from Rhei Rhizoma are activated by human intestinal

bacteria. Arch Pharm Res, 25:528-533, 2002.

- Cheong H,

Ryu SY, and Kim KM. Anti-allergic action of resveratrol and related

hydroxystilbenes. Planta Med, 65:266-268, 1999.

- Kim DH,

Park EK, Bae EA, Han MJ. Metabolism of rhaponticin and chrysophanol

8-o-beta-D-glucopyranoside from the rhizome of Rheum undulatum by human

intestinal bacteria and their anti-allergic actions. Biol Pharm Bull, 23:830-833, 2000.

- Aburjai TA.

Anti-platelet stilbenes from the aerial parts of Rheum palaestinum.

Phytochem, 55:407-410, 2000.

- Aggarwal

BB, Bhardwaj A, Aggarwal RS, Seeram NP, Shishodia S, Takada Y. Role of resveratrol in

prevention and therapy of cancer: preclinical and clinical studies. Anti-cancer

Res, 24:2783-2840, 2004.

- Chun

YJ, Ryu SY, Jeong TC, Kim MY. Mechanism-based inhibition of human

Cytochrome P450 1A1 by rhapontigenin. Drug Met Disp, 29:389-393, 2000.

- Guengerich

FP, Chun Y, Kim D, Gilliam EMJ, Shimada T.

Cytochrome P450 1B1: A target for inhibition in anticarcinogenesis

strategies. Mut Res, 182:523-524, 2003.

- Causon R.

Validation of chromatographic methods in biomedical analysis viewpoint and

discussion. J Chrom B, 689:175-180, 1997.

- Teng XW, Cutler DJ, and Davies NM. Kinetics of metabolism and

degradation of mometasone furoate in rat biological fluids and tissues. J

Pharm Pharmacol, 55:617-630, 2003.

- Roupe K,

Teng XW, Fu X, Meadows GG, Davies

NM. Determination of piceatannol in rat serum and liver

microsomes: pharmacokinetics and phase I and II biotransformation. Biomed

Chromatogr, 18:486-491, 2004.

- O’Brien J, Wilson I, Orton T, Pognan F. Investigation of the

Alamar Blue (resazurin) fluorescent dye for the assessment of mammalian

cell cytotoxicity. Eur J Biochem, 267:5421-5426, 2000.

- Roupe K,

Halls S, Davies NM. Determination

and assay validation of pinosylvin in rat serum: application to drug

metabolism and pharmacokinetics. J Pharm Biomed Anal, 38:148-154, 2005.

- Yanez JA,

Teng XW, Roupe KA, Davies NM. Stereospecific high-performance liquid

chromatographic analysis of hesperetin in biological matrices. J Pharm

Biomed Anal, 37:591-595, 2005.

- Skeith KJ, Dasgupta M, Lange R, Jamali F. The influence of renal function on the

pharmacokinetics of unchanged and acyl-glucuroconjugated ketoprofen

enantiomers after 50 and 100 mg racemic ketoprofen.Br J Clin Pharmacol,

42:163-169, 1996.

- Marier JF,

Vachon P, Gritsas A, Zhang J, Moreau JP, Ducharme MP. Metabolism and disposition of

resveratrol in rats: extent of absorption, glucuronidation, and

enterohepatic recirculation evidenced by a linked-rat model. J Pharmacol

Exp Ther, 302:369-373, 2002.

JPPS Contents

Published by the Canadian Society

for Pharmaceutical Sciences.

Copyright © 1998 by the Canadian

Society for Pharmaceutical Sciences.

http://www.cspscanada.org/

CSPS Home |

JPPS Home |

Search |

Subscribe to JPPS