J Pharm Pharmaceut Sci (www.cspscanada.org) 8(3):409-418, 2005

Development of cyclodextrin microspheres

for pulmonary drug delivery

Malika Skiba, Frédéric Bounoure, Cécile Barbot,

Philippe Arnaud, Mohamed Skiba

Laboratoire de Pharmacie

Galénique et Biopharmacie, ADEN-UPRES EA

3234, UFR de Medecine-Pharmacie, Rouen Cedex, France

Received March 1, 2005 ,Revised June 21, 2005, Accepted June 28, 2005, Published August 24, 2005

Corresponding author. Mohamed Skiba Laboratoire de Pharmacie Galénique et Biopharmacie, ADEN-UPRES EA 3234, UFR de

Medecine-Pharmacie, 22 Boulevard Gambetta, 76183 Rouen Cedex, France.

ABSTRACT

Purpose. Microparticles of

diameter < 5 mm were synthesized

by interfacial cross-linking of 7.5% (w/v) b-cyclodextrins (b-CD) with 4.5%

(w/v) terephtaloyle chloride in 1 M NaOH, in order to provide stable vector for

drug encapsulation suitable for administration at the alveolar scale. Methods. Batches were prepared varying

different parameters such as amount of monomer (b-CD) (5-30% w/v), NaOH

concentration (0.5-4 M), reaction time (15-240 min), agitation rate (8000-24000

rpm), amount of cross-linking agent (terephtaloyle chloride: 1.25-10% w/v),

surfactant percentage (2.5-10% of Span 85), studying the influence of the

freeze-drying step. Microparticles were controlled with respect to their size

by a laser diffraction technique, pH of the colloidal suspension, IR

spectroscopy, Differential Scanning Calorimetry. After optimization of the

microparticles size, complexation with amikacin sulfate was investigated

comparing encapsulation efficiency and yield at each step of the preparation

(solubilization, emulsification, cross-linking, freeze-drying), contact time

and influence of the amount of amikacin. Results.

An optimized method was obtained with 1 M NaOH, 4.5% (w/v) cross-linking agent

and 5% (w/v) surfactant agent, a 30 min reaction time, a 24000 rpm agitation

rate, conducting to microparticles whose size is inferior to 5 mm. Amikacin sulfate

encapsulation in polycondensed b-cyclodextrin showed

that better incorporation was obtained during the solubilization step or just

before freeze-drying. Conclusions.

Amikacin encapsulation in 5 mm diameter

microparticles of b-CD is achievable

for pulmonary drug delivery.

INTRODUCTION

Native cyclodextrins are

polysaccharides made up of six to eight cyclic linked oligosaccharides of

D-glucopyranose monomers connected by a-1, 4-indican

bonds. These compounds form cone-shaped molecules with primary hydroxyl groups

(6-OH) arranged in an inner hydrophobic cavity of 5.7, 7.8 and 9.5 Å

respectively for a-, b-, g-cyclodextrins, and

secondary hydroxyl groups (2- and 3-OH) rendering external walls hydrophilic

(1). These two microenvironments confer to the molecule the ability of forming

inclusion complex with guest molecules. Cyclodextrins act as molecular hosts

toward various, poorly water-soluble drugs, ranging from ion, very polar

molecules to non-polar molecules, affecting advantageously their

physicochemical properties (2, 3). Thus, they have found extensive applications

in chromatography, catalysis, asymmetric reactions, food, cosmetic,

pharmaceutical technology (4), medicinal applications. Partially or entirely

encapsulation occurs by the intermediate of hydrophobic forces and van der

Waals interactions, ion pairing, hydrogen bonding (5) participating in

improving, through complexation, the aqueous solubility and stability of drugs

(6-8), vitamins and food colorant, preventing molecules self-aggregation,

ameliorating dissolution rate, bioavailability of the hydrophobic drugs,

decreasing toxicity and controlling drug releasing (9-11).

Scheme 1. Preparation of the CD microparticles with

terephtaloyle chloride.

Preparation of

inclusion complexes (4, 12, 13) can be done by different methods namely,

coprecipitation, freeze-drying, kneading, grinding or co-pulverizing, microwave

heating (14). Inclusion complexes can be formed in solution or in a solid state

(15). The advantage of the preparation in the crystalline state is the

protection of the complexes formed against some type of reactions such as

oxidation, hydrolysis and the role played in the decrease of their sublimation

and volatility (16). Guests of varying size were tested by many authors,

screening their physicochemical features in function of various stoechiometric

ratios (17, 18).

Analytical methods

for physicochemical characterization used are fluorescence spectroscopy (steady

state fluorescence), NMR spectroscopy, IR (19), differential scanning

calorimetry (DSC), elemental analysis, power X-ray diffraction, thermogravimetric

analysis (TGA). When complexed with CDs, modification in the photoreactivity

(20, 21) of the guest molecule occurs and generally fluorescence efficiencies

are enhanced (22, 23) due to a decrease in non-radiative and quenching

processes observed in bulk solution (24, 25). Fluorimetric analysis is also

used due to its sensibility and selectivity to evaluate association constants

of complexes (26-28). NMR gives useful informations about the geometry of

complexes (29-31). Therefore, cyclodextrin microspheres have been shown to be

stable vectors for drug encapsulation (10, 30) and may have some applications

in pulmonary drug delivery when deposited in the alveolar region.

Two methods for the

preparation of drug-containing CD particles are described in the litterature.

The first one involves cross-linking drug directly to CDs adsorbed on a porous

inorganic oxide via a bifunctional agent, epichlorydrin (32) or sebacoyle

chloride (33). The second one requires the synthesis of 10-35 mm microcapsules, in an

emulsion system, and subsequent interfacial cross-linking of b-cyclodextrin (b-CD) with

terephtaloyle chloride (34). In this paper, we describe our efforts to optimize

the second method to produce 5 mm particles intended for

alveolar drug delivery following inhalation. Some authors prepared

microparticles, with a mean geometric size inferior to 5 mm, from an oil-in-water

emulsion consisting of an aqueous phase containing cyclodextrin derivative

(35). The first goal of our investigation was devoted to the preparation of

microparticles from native cyclodextrins synthesized by interfacial

cross-linking with terephtaloyle chloride. We measured the influence of

reaction conditions on the resulting microparticle size. Once our objectives

were reached, fabrication yield and pH of the colloidal suspension (nearest

physiological pH) were optimized and microparticles characterized by

granulometry, FT-IR and DSC. The second part of the study concerned the

microparticle complexing properties with amikacin sulfate (Figure 1), a

potential drug to be administered in pulmonary disease. The effects of

variations in the preparation conditions of encapsulated microparticles were

investigated. Amikacin is an antibiotic of the class of aminosides used in the

treatment of severe infections, particularly those due to aerobic,

Gram-negative bacilli (GNB). Their main drawback has been the occurrence of

(reversible) nephrotoxicity and ototoxicity in a significant number of patients

Nosocomial pneumonia with GNB is the first cause of infection mortality for

patients requiring mechanical ventilation. The pulmonary targeting through

encapsulation of this antibiotic into cyclodextrin microspheres seems to be

interesting to optimize therapeutic efficacy and limit it’s toxicity. Particular

system based on cyclodextrin microspheres presents a great stability, a high

encapsulation efficiency and allows drug spray-drying at the alveolar scale as

compared with other drug delivery systems.

Figure 1. Amikacin sulfate.

Microspheres were

synthesized by interfacial cross-linking of b-cyclodextrins (b-CD) with

terephtaloyle chloride in 1 M NaOH (Scheme 1). A series of batches were

prepared in which formulation parameters such as monomer concentration (5-30%

w/v), NaOH concentration (0.5-4M), reaction time (15-240min), agitation rate

(8,000-24,000 rpm), polymerization agent concentration (1.25-10% w/v), and

surfactant content (2.5-10% of Span 85) were varied. The influence of

freeze-drying on the particles size was also investigated. Microspheres size

and pH of the colloidal suspension were optimized around two objectives. (1)

The maximum yield of particles smaller than 5mm, measured by a laser

diffraction technique, and (2) pH nearest to physiological pH. Following size

and pH optimization, amikacin sulfate was encapsulated into the microspheres at

four different stages of the fabrication process (solubilization,

emulsification, cross-linking and freeze-drying) and the encapsulation

efficiency (mass of amikacin sulfate in particles (mg)/ mass of b-CD (mg)) and yield

(mass of amikacin sulfate in particles (mg)*100/mass of amikacin

sulfate introduced (mg)) were determined

by a HPLC method (36).

MATERIAL

AND METHODS

Material

Amikacin sulfate was purchased

from Bristol-Myers Squibb (France). b-cyclodextrin was

obtained from Roquette Frères (

Preparation

of microparticles

Polycondensation of b-cyclodextrin by

terephtaloyle chloride was undertaken by the following standard method :

In a first step, 6

mL of b-CD (7.5% w/v) was

solubilized in 1M NaOH and emulsified during 10 min, using a Heidolph RGL 500

stirring motor (Prolabo, France) at a stirring rate of 2000 rpm, in a 30

mL-cyclohexane solution containing 5% (v/v) sorbitan 85 trioleate, at ambiant

temperature.-

-Cross-linking solution was

prepared dissolving 5% (w/v) terephtaloyle chloride in a (1:4, v/v) mixture

chloroform/cyclohexane.

- Microparticles were formed by addition of this organic

phase to the emulsion, and mixing with 30 min stirring, the agitation speed

being regulated to 2000 rpm. In this study, on contrary to the standard method,

agitation rate was regulated to 8000 rpm (Ultra Turrax type TP 18/10 Janke et

Kunkel). This cross-linking reaction was stopped by dilution with 40 mL

cyclohexane.

The microparticles

thus formed were separated by centrifugation (5 min, 3000 rpm), washed

successively with cyclohexane, a 95% ethanol solution containing 2% (v/v)

polysorbate 20, 95% ethanol and finally with distilled water.

In the last step,

the colloidal suspension obtained was freeze-dried (Lyophilisator Virtisâ Advantage, vacuum <200 mTorr,

condenser <-40°C, plate +30°C).

Influence of

different parameters was studied, introducing variations in the standard

procedure : amount of monomer, NaOH concentration, reaction time, agitation

rate, amount of cross-linking agent and amount of surfactant. All formulations

were prepared three times.

Physicochemical

characterization of the particles

Influence of these parameters

was studied controlling the size of the particles formed by a laser diffraction

technique (granulometer Coulter LS 100,

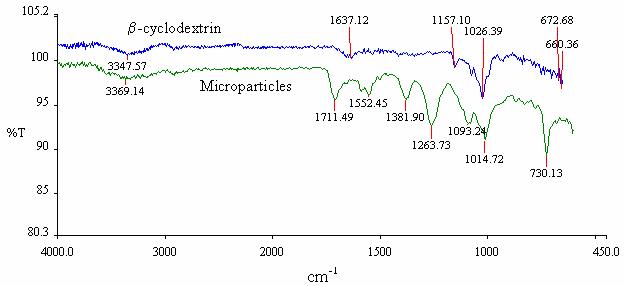

IR analysis

The FT-IR spectra acquired

were taken from dried samples. A FT-IR (Spectrum One®, Lita

detector, MIR source and FT-IR Spectrum® software from Perkin Elmer)

was used for the analysis in the frequency range between 4000 and 600 cm-1,

a 8 cm-1 resolution and a 0.2 cm-1 rate. The results were

the means of 16 determinations. Physical mixtures of microparticles and active

drug (1/1) were used as blanks.

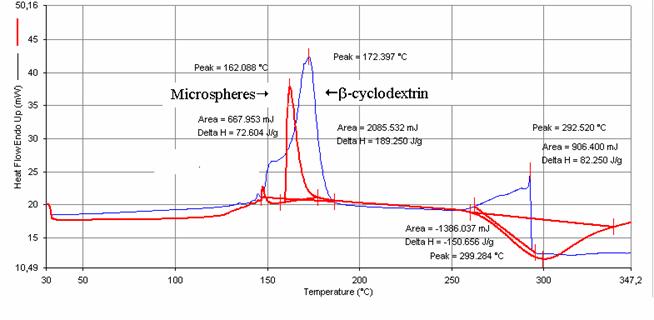

Differential scanning

calorimetry (DSC)

Thermal analysis was performed

using a DSC 6 calorimeter equipped with a Pyris® software (Perkin

Elmer). All samples were heated at a 10°C min-1 scanning rate

between 30-350°C after a 1 min stabilization plate at 30°C/20 mW, under

nitrogen atmosphere. Thermograms are expressed in °C = f(mW). Physical mixtures

of b-CD microparticles

with amikacin (1/1) are used as blanks.

Encapsulation

of hydrosoluble substances

Amikacin sulfate was

encapsulated at two different steps of the fabrication :

-encapsulation during the

microparticles fabrication process (solubilization, emulsification,

cross-linking, freeze-drying),

- Encapsulation with the synthesized microparticles

controlling the contact time and the influence of amikacin sulfate amount.

Influence of contact time

A series of experiments were

conducted increasing contact time (15-60 min) between colloidal suspension (100

mL) and amikacin

amount (500 mg). Results show

that equilibrium is reached rapidly, the plate being reached after 30 min

incubation time (Figure11).

Influence of amikacin sulfate

The volume of colloidal

suspension is maintained at 50 mL, with a contact

time fixed at 60 min. Encapsulation efficiency and yield increase linearly with

the amount of amikacin introduced (Figure 11).

Statistical

Analysis

Statistical data analyses were

performed using the Student’s t-test at p < 0.05.

Results and discussion

Microparticles

synthesis

Influence of reactions

parameters on the size of microparticles

Elaboration of 5 mm microparticles

size by interfacial polycondensation of b-CD with the cross-linking

agent, terephtaloyle chloride, was undertaken and assayed varying different

parameters, from the standard procedure.

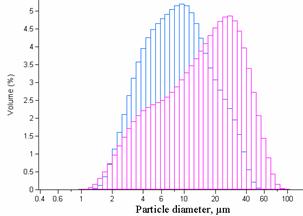

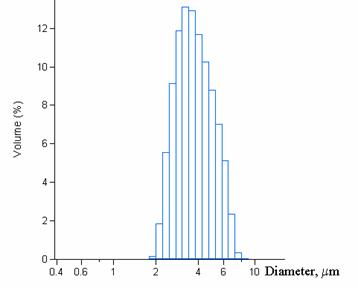

Figure 2. Granulometric features of the obtained

particles by the standard method with 0.5 M (right) and 1 M NaOH (left) (b-CD: 7.5%w/v, 1M NaOH, 30 min reaction time,

8000 rpm agitation rate, polymerization and surfactant agent: 5% w/v). For

unimodal repartition (1M NaOH: n=3, mean=8.549±2.089mm).

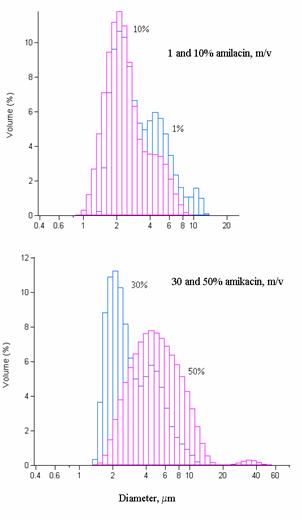

The size of the

particles formed increased respectively with the b-CD amount, with NaOH

concentration (Table 1), only with concentration above 1M and the step of

freeze-drying. NaOH concentration lower than 1 M produced a bimodal repartition

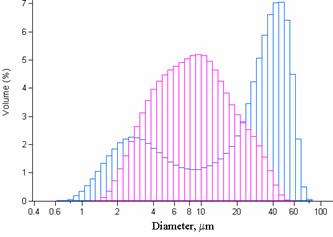

of the particles size (Figure 2). Freeze-drying increased the median

microspheres size from 8.7 to 15.3 mm, in a bimodal

repartition (Figure 3) modifying the studied population granulometry features

due to particles agglomeration. On contrary, the size of the particles was

minimal at 5-10% (v/v) of surfactant and at maximal agitation rate (24000 rpm)

(Table 1). The surfactant amount and the agitation rate were determinant in the

emulsification step and crucial for the formation of the smallest particles. An

optimized method was elaborated, modifying the agitation speed to 24 000 rpm

and decreasing the concentration of cross-linking agent to 4.5% (w/v), a concentration

that don't affect the microspheres size, yield and unimodal repartition. This

new preparation method allowed the formation of particles with size inferior to

5 mm (Figure 4) with a

high reproductibility.

Stability assay, on

the form of colloidal suspension were undertaken at ambiant temperature and at

4°C. Results obtained showed a physical stability of uncharged particles for at

least three months at ambiant temperature. At lower temperatures, conservation

of colloidal suspension was more difficult due to an increased sensitivity to

crystallization phenomenon.

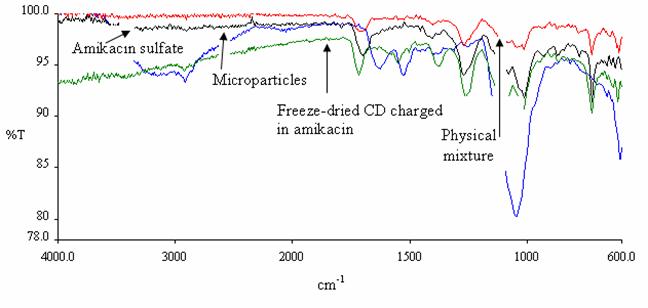

FT-IR spectra

The spectrum of microparticles

formed with the optimized method was compared with the spectrum of original b-CD. Three bands

appeared in microparticle spectrum at 1711, 1263 and 730 cm-1, due

to the formation of esters from hydroxy groups of the b-CD (Figure 5). The mechanisms

have been studied by reaction of b-CD treated with 1

equivalent of terephtaloyle chloride in pyridine (37).

Table 1. Influence of preparation parameters

on mean microparticle size, colloidal suspension pH and yield, when varied

independently from the standard formulation (b-CD: 7.5%w/v, 1M NaOH, 30 min

reaction time, 8000 rpm agitation rate, polymerization and surfactant agent: 5%

w/v) (n=3). The optimized formulation is shown in bold.

|

Parameter |

Value |

pH |

Mean size (mm) ±SD |

Mean yield (%) ±SD |

|

Monomer amount (% w/v) |

5 |

2.68 |

7.89±1.10 |

26.7 ± 3.3 |

|

7.5 |

2.74 |

6.31±1.23 |

26.5± 3.0 |

|

|

10 |

2.89 |

8.92±1.20 |

25.5 ± 3.1 |

|

|

20 |

2.67 |

10.64±0.51 |

27.7 ± 2.9 |

|

|

30 |

2.95 |

12.78±0.45 |

28.4 ± 2.8 |

|

|

NaOH (M) |

0.5 |

1.95 |

15.78±0.97 |

18.1 ± 2.5 |

|

1 |

2.69 |

8.52±1.12 |

28.9 ± 3.5 |

|

|

2 |

3.80 |

10.82±0.74 |

34.7 ± 2.6 |

|

|

4 |

5.60 |

12.79±0.88 |

53.1 ± 4.2 |

|

|

Reaction time (min) |

15 |

2.84 |

17.19±1.51 |

27.5 ± 2.5 |

|

30 |

2.70 |

8.43±0.57 |

29.4 ± 2.1 |

|

|

60 |

2.64 |

8.38±0.35 |

32.8 ± 2.4 |

|

|

120 |

2.95 |

8.71±0.52 |

35.5 ± 2.6 |

|

|

240 |

2.67 |

8.11±0.76 |

36.6 ± 2.5 |

|

|

Surfactant amount (% v/v) |

2.5 |

2.68 |

12.97±0.81 |

24.9 ± 2.4 |

|

5 |

2.71 |

8.25±0.42 |

26.8 ± 2.9 |

|

|

10 |

2.61 |

8.59±0.59 |

27.9 ± 2.5 |

|

|

Cross-linking agent (% w/v) |

1.25 |

6.73 |

13.48±0.61 |

18.8 ± 1.5 |

|

2.5 |

5.10 |

9.56±0.52 |

21.9 ± 2.8 |

|

|

3.75 |

3.90 |

8.56±0.53 |

29.9 ± 2.7 |

|

|

5 |

2.69 |

8.69±0.46 |

28.7 ± 3.4 |

|

|

6.25 |

1.91 |

8.98±0.47 |

27.4 ± 2.6 |

|

|

7.5 |

1.56 |

8.68±0.41 |

28.6 ± 2.5 |

|

|

8.75 |

1.69 |

8.90±0.34 |

29.5 ± 2.4 |

|

|

10 |

1.09 |

8.80±0.46 |

27.5 ± 2.7 |

|

|

Agitation rate (rpm) |

8,000 |

2.64 |

8.68±0.65 |

25.6 ± 2.7 |

|

9,500 |

2.79 |

8.29±0.74 |

27.9 ± 2.5 |

|

|

13,500 |

2.84 |

6.15±0.34 |

28.1 ± 3.5 |

|

|

24,000 |

2.83 |

4.54±0.22 |

29.8 ± 1.2 |

DSC

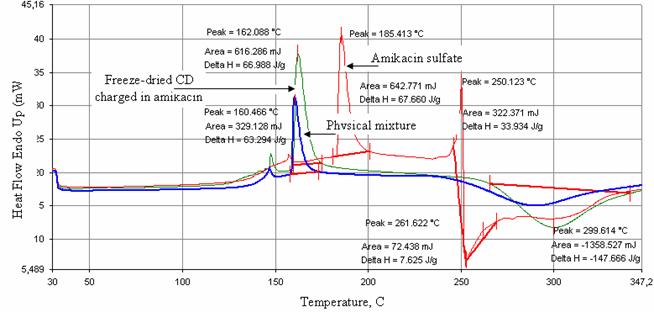

No observable signal was

present in the temperature range 30-115°C (Figure 6). At 172.4°C, an endotherm

peak responsible for the cyclodextrin melting was observed whereas it was

displaced at 162°C for reticulated cyclodextrin. At 300°C, an additional

exothermic peak was attributed to terephtaloyle chloride.

Figure 3. Granulometric features of the obtained

particles by the standard method before freeze-drying step (unimodal) and after

freeze-drying step (bimodal) (b-CD: 7.5%w/v, 1M NaOH, 30 min

reaction time, 8000 rpm agitation rate, polymerization and surfactant agent: 5%

w/v). For unimodal repartition (before freeze-drying: n=3, mean=8.549±2.089mm).

Figure 4. Granulometric features of the obtained

particles for the optimized formulation (n=5 ; pH = 3.65±0.13; size=3.72±1.34 mm ; yield =28.5±1.4%) (b-CD: 7.5%w/v, 1M NaOH, 30 min

reaction time, 24000 rpm agitation rate, polymerization agent: 4.5% w/v and

surfactant agent: 5% w/v).

Amikacin sulfate encapsulation

in b-CD microparticles

Encapsulation during

microparticles fabrication process

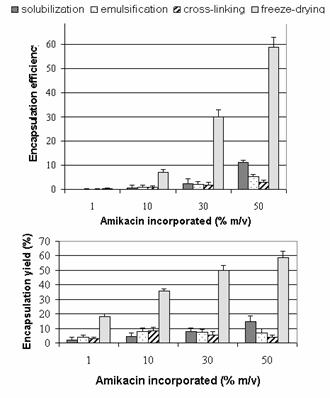

Encapsulation efficiency (mass

of amikacin sulfate in particles (mg)/ mass of b-CD (mg)) (Figure 7)

increased linearly with the amikacin sulfate incorporated due to the fact that b-CD must be in

excess over the amikacin sulfate incorporated. Encapsulation was more

pronounced for solubilization and freeze-drying step. Encapsulation yield (mass

of amikacin sulfate in particles (mg)*100/mass of

amikacin sulfate introduced (mg)) (Figure 7)

increased for the step of solubilization and freeze-drying reaching a plate

from 20 mg amikacin. On

contrary, yields were constant from 10 mg for emulsification step and

even decreased from 10 mg for cross-linking

step.

Encapsulation with

microparticles

Ganulometry measurements were

represented in function of% (m/v) amikacin introduced in the microsphere

solution (Figure 8). Until 50% (m/v) amikacin, a bimodal repartition of the

complexed amikacin was observed with a maximum size of particles around 3 mm (1% 3.136±1.689 mm ; 10% 2.433±1.541

mm ; 30% 2.970±1.603

mm). When 50%

amikacin was put into contact with microspheres, a maximum size centered on

4.968±1.689 mm with an unimodal

repartition was obtained reaching a limit for pulmonary drug delivery at

alveolar scale.

Freeze-drying of a b-CD colloidal

suspension and amikacin sulfate gave a chemical entity whose thermic features

superpose to the host particle (Figure 9).

The thermogram

(Figure 9) and IR spectra (Figure 10) of amikacin charged freeze-dried

cyclodextrin and that corresponding to physical mixture compared with amikacin

sulfate did not show the reapparition of the signal characteristic of amikacin

sulfate. Therefore, this phenomenon can be attributed to dilution of the active

substance in the powder. The nature of the interactions between amikacin and

cyclodextrins remains unknown. Two hypotheses can be emitted : either the

amikacin molecule forms partially or wholly an inclusion complex with

cyclodextrins or one of the reaction functions of amikacin reacts with hydroxyl

groups from cyclodextrin to create an hydrogen bond.

The first

hypothesis seems unlikely because inclusion complexes are observed with

hydrophobic compounds which insert inside the hydrophobic