J Pharm Pharmaceut Sci

(www.cspscanada.org) 8(3):593-600, 2005

Efficient size control of amphiphilic

cyclodextrin nanoparticles through a statistical mixture design methodology

Luc Choisnard1,

Annabelle Géze1, Muriel Bigan2, Jean-Luc Putaux3,

Denis Wouessidjewe1

1Université Joseph Fournier – UFR

Pharmacie – DPM UMR 5063 CNRS– Pharmacotechnie, Avenue de Verdun. Meylan cedex

2Université des Sciences et Technologies de

Lille – LCOM - UMR 8009 CNRS - Cité Scientifique Villeneuve d’Ascq cedex

3Centre de Recherche sur les Macromolécules

Végétales - UPR 5301 CNRS Grenoble Cedex

Received June 27, 2005; Revised November 24,

2005, Accepted November 25, 2005, Published December 6, 2005

PDF Version

ABSTRACT Purpose: the aim of

the study was to investigate size control of amphiphilic β-cyclodextrin

nanoparticles obtained by solvent displacement technique. Methods: An experimental design methodology for mixture

design was undertaken using D-optimal approach with the following technique variables:

water fraction X1 (40-70% v/v), acetone fraction

X2 (0-60% v/v) and ethanol fraction X3 (0-60% v/v). Results: The resulting quadratic model obtained after

logarithmic transformation of data and partial least-square regression was statistically validated and experimentally checked. Also,

the morphology of the colloidal nanoparticles from selected experiments was observed

by cryo-transmission

electron microscopy. Conclusions: This experimental

design approach allowed to produce interesting

amphiphilic b-cyclodextrin nanoparticles with a predicted mean

size varying from 60 to 400 nm.

INTRODUCTION

In the pharmaceutical industry, natural

or modified cyclodextrins are interesting excipients to reduce toxicity while

improving stability, solubility and bioavailability of hydrophobic drugs.

Amphiphilic b-cyclodextrins obtained by grafting hexanoic chains

on the secondary hydroxyl groups have the ability to self-organize yielding

stable supramolecular assemblies using the nanoprecipitation technique. These amphiphilic b-cyclodextrin

nanoparticles could be considered as promising carriers for drug molecules (1, 2). In a previous

study, Gèze et al. (3) have

established the correlation between the chemical structure of amphiphilic b-cyclodextrin and their ability to form stable

nanospheres. More recently, the long-term shelf stability of the nanoparticles

was also monitored by photo correlation spectroscopy and cryo-transmission

electron microscopy (4).

The

nanoparticle capacity to associate drug is partially expected to be influenced

by nanoparticle size. This latter parameter could be related to the nature and the

amount of organic solvent involved during nanoparticle manufacturing. The

mechanism of nanoparticle formation is complex and has only been partially understood

(5) although numerous monographs and review articles have been written on the

subject. Then, one

of the major challenges for the design of the colloidal carriers is to define a

solvent or a solvent mixture system suitable to obtain a desired size. However,

one has to keep in mind that, the properties (Mw, polarity,…)

of the drug when associated to amphiphilic b-cyclodextrins carriers,

may also influence the size as well as the bulk structure of the nanoparticles.

The aim of the present work was to set up

experimental procedures allowing the control of nanoparticle size during their

manufacturing. This goal was achieved by using mixture

design methodology in which an empirical correlation was found between the

solvent proportion (water/acetone/ethanol) and the nanoparticle size. In

addition, the morphology and internal structure of the nanoparticles were investigated using cryo-transmission electron

microscopy (cryo-TEM) experiments.

MATERIALS AND METHODS

Natural b-cyclodextrin (b-CD), Kleptose®,

was obtained from Roquette (Lestrem,

France). Anhydrous

pyridine (99%), dichloromethane (99%) and 2, 4-dimethylaminopyridine, hexanoyl

chloride, were purchased from Aldrich. Tetrabutylammoniumfluoride and

tetrahydrofuran were from Avogado and Acros respectively. Ethanol and acetone at

pharmaceutical grade, methanol, cyclohexane and chloroform were purchased from

Sodipro (Grenoble, France). Water was distilled in our

laboratory.

Amphiphilic b-cyclodextrin synthesis

Amphiphilic b-cyclodextrin was prepared with a 3 step procedure from

natural b-cyclodextrin according to a modified procedure described

by Lesieur et al. (6) and Dubes et al. (7): i) protection of primary hydroxyl groups, ii)

acylation of secondary face, iii) deprotection of primary face.

(I) Dried b-cyclodextrin (1g, 1eq.) was mixed

with TBDMSCl (1g, 8eq.) in anhydrous pyridine (40ml) at room temperature under

N2 for 48 hours. The product was precipitated in ice-cooled water,

filtered and washed twice with ice-cooled water. The dried crude product was

then dissolved in a minimum quantity of chloroform and purified by column

chromatography using chloroform/methanol/water (8/1.9/0.1, v/v/v,) as mobile

phase. The pure Heptakis(6-O-tert-butyldimethylsilyl)

cyclomaltoheptaose was obtained with yield of 76%.

(II)

Hexanoyl chloride

(3ml, 42 eq.) was added to a stirred solution of heptakis(6-O-tert-butyldimethylsilyl)

cyclomaltoheptaose (1g, 1 eq.) and 2, 4-dimethylaminopyridine (3g, 49 eq.) in

anhydrous pyridine (40ml). The mixture was heated at 70°C for

48 h, then cooled to room temperature and poured into a large volume of

ice-cooled water. The aqueous phase was removed

by settling and the syrupy residue taken up into dichloromethane. After washing

with dilute sulphuric acid (2%), water and aqueous sodium hydrogen carbonate,

the organic layer was dried (Na2SO4) and concentrated to

a residue which was submitted to flash chromatography using cyclohexane/ethyl

acetate (10/1) as mobile phase.

(III) Tetrabutylammonium fluoride 1M in tetrahydrofuran (3ml, 8 eq.) was added

drop-wise to a stirred anhydrous

tetrahydrofuran (28 ml, eq.) solution of the resulting product (1g, 1 eq.)

obtained from step (II). The mixture was reacted at room temperature under N2

for 44h. The crude

product was then concentrated to dryness and submitted to flash chromatography using ethyl

acetate/cyclohexane/ethanol (8/1.9/0.1, v/v/v,) as mobile phase.

Nanosphere preparation

The nanosphere suspensions were

prepared using

the nanoprecipitation technique firstly developed by LaMer and Dinegar (8) and

applied to amphiphilic cyclodextrin by Skiba et al. (9) 20 mg of b-CDa were

dissolved at 25°C in an organic solvent constituted by acetone or ethanol or in

an acetone/ethanol mixture. The organic solution was poured

slowly through a silicon tube fitted with fine tip into distilled water subjected

to a magnetic stirring. The organic solvents and water volume of each

experiment unit were defined according to an experimental

design worksheet (table 2). The nanospheres were formed

immediately and the colloidal suspension obtained was subjected to evaporation

under reduced pressure to remove organic solvent. The colloidal suspension

obtained was filtered through a 0.8 µm membrane (Millex AA, Millipore, France)

and stored in closed vials at room temperature.

Particle size measurements

The size of the nanospheres was

measured using quasi-elastic light scattering (QELS) with a Zetasiser 3000

instrument (10 mW HeNe laser at 632.8 nm, K7132 correlator, Malvern Instrument,

Malvern, UK). Experimental conditions were the following : temperature 25±0.1°C, reference angle 90°C, viscosity 0,899´10-3 Pa.s, refractive index of the dispersant 1.330. The mean

hydrodynamic diameter of the particles was calculated

using a Contin algorithm with Zetasizer 3000. All the experimental units were analysed in

triplicate.

Transmission electron microscopy

According to the procedure

described elsewhere (10), specimens for cryo-TEM were prepared by

quench-freezing thin liquid films of 0.1% (w/v) amphiphilic b-cyclodextrin nanostructure suspension into liquefied ethane

(-171°C). Once transferred into a Gatan 626 cryoholder, the specimens were

observed at low temperature (-180°C), using a Philips CM200 “Cryo” microscope

operating at 80kV. Micrographs were recorded on Kodak SO163 films.

Experimental design

The influence

of the water/acetone/ethanol mixture on the nanoparticle size was investigated by an experimental design methodology. In

our objectives, the experimental design was chosen to

support a quadratic regression model as adequate to estimate a potentially

complex response function (equation 1).

(1)

(1)

Where h is the simulation model response, b0 the constant, bi the linear coefficients, bij the interaction coefficients, bii the quadratic coefficients, k the number of

critical variables Xi and e the random error term.

The

solvent fraction levels, which limit the experimental field, were determined

after some preliminary studies. First, due to the high solubility of bCDa in organic solvents, i.e., acetone and ethanol,

nanoprecipitation that occurs via solvent shifting, was not satisfactory when

the amount of water in the medium was under 40%. Secondary, when the amount of

water in the medium was higher than 70%, the low final nanoparticle

concentration in water, following removal of organic solvent, made the

measurement difficult to perform (low limit of scattering intensity). Indeed, nanoparticles

were finally so diluted in aqueous phase that an efficient measure was unfeasible

with the Zetasiser 3000

instrument. No specific

distinctions were postulated between the amount of acetone and ethanol amounts.

The component limits are summarized in

table1.

Standard three-component design

might require too many experiments because all the components

are restricted by upper (X2, X3) or upper and lower (X1)

constraints. Then, mixture solvent formulation was

investigated using a D-optimal design approach (11). D-optimal

design was computed by MODDE v5.0 software (UMETRICS AB, Box 7960, SE-90719

Umeå Sweden)

in twelve experiment units including two central replicates to estimate pure

error. G-efficiency criterion was used to select the

optimal worksheet design set. Finally, run sequence of experimental units was completely randomized to minimize the effect of noise

and then safeguarding the experiment from systematic bias (table 2). All

experiments were performed without replication.

Table 1: Settings levels for each mixture component.

|

labels

|

fraction

|

levels

setting

|

|

low

|

high

|

|

X1

|

U1,

water

|

40% (v/v)

|

70% (v/v)

|

|

X2

|

U2,

acetone

|

0% (v/v)

|

60% (v/v)

|

|

X3

|

U3,

ethanol

|

0% (v/v)

|

60%(v/v)

|

Table 2: Design matrix (G-Efficiency = 69.63), experimental worksheet and

corresponding nanoparticle size response.

|

Experimental

unit

|

Coded

variable

|

Natural

variable

|

Size

±

SD

(nm)

|

IP

|

|

X1

|

X2

|

X3

|

U1

(ml)

|

U2

(ml)

|

U3

(ml)

|

|

1

|

0

|

1

|

0

|

8

|

12

|

0

|

198±12

|

0.06

|

|

2

|

0

|

0

|

1

|

8

|

0

|

12

|

467±4

|

0.57

|

|

3

|

0.5

|

0.5

|

0

|

14

|

6

|

0

|

59±1

|

0.08

|

|

4

|

0.5

|

0

|

0.5

|

14

|

0

|

6

|

67±2

|

0.07

|

|

5

|

0.167

|

0

|

0.833

|

10

|

0

|

10

|

178±11

|

0.18

|

|

6

|

0.333

|

0

|

0.667

|

12

|

0

|

8

|

101±7

|

0.09

|

|

7

|

0.167

|

0.833

|

0

|

10

|

10

|

0

|

108±4

|

0.18

|

|

8

|

0.333

|

0.667

|

0

|

12

|

8

|

0

|

79±3

|

0.07

|

|

9

|

0

|

0.667

|

0.333

|

8

|

8

|

4

|

311±14

|

0.24

|

|

10

|

0

|

0.333

|

0.667

|

8

|

4

|

8

|

387±31

|

0.31

|

|

11

|

0.25

|

0.375

|

0.375

|

11

|

4.5

|

4.5

|

96±3

|

0.06

|

|

12

|

0.25

|

0.375

|

0.375

|

11

|

4.5

|

4.5

|

92±2

|

0.05

|

RESULTS AND DISCUSSIONS

The

objective of the present study was to control the amphiphilic cyclodextrin

self-assembly process to form nanoparticle with the desired size. First,

the amphiphilic cyclodextrins were classically synthesized

in three steps from the natural β-CD as summarized in

figure 1: i) protection of primary hydroxyl groups, ii) acylation of the

secondary face, iii) deprotection of primary face. The

amphiphilic cyclodextrin products obtained was characterized as a statistical

mixture of β-CD variously acylated. The degree of acylation of the secondary alcohol is

theoretically 14 for the b-cyclodextrin. However, it is perfectly known that

in the presence of a large amount of DMAP self-condensation of acyl chains may

occur and hence, leading to the increase of grafted hexanoyl chains on the

β-CD (6, 7, 12). As described in figure 1, this synthesis leads to

a statistical mixture of multisubstituted b-cyclodextrin

containing under and over-acylated b-cyclodextrin

by hexanoyl chains.

Figure 1: Schematic pathway for amphiphilic b-cyclodextrin

synthesis

Then, the electrospray mass

spectrometry characterization clearly demonstrated the presence of a mixture of

numerous derivatives resulting from coupling of 8 to 23 alkanoyl chains (m/z

[M+Na] = 1941.8 to 3412.9).

This

product was used to obtain nanoparticles using nanoprecipitation procedure. The

influence of water/acetone/ethanol mixture ratios involved in the

nanoprecipitation technique on the nanoparticle size response was investigated

by experimental design methodology. Five classical steps were carried out:

choosing adequate model and performing the experimental worksheet as decrypted

in experimental section, fitting the model coefficients, predicting the

response and checking the adequacy of the model (13, 14).

Nanoparticle sizes, standard deviations

(SD) and index of polydispersity (IP) of experimental worksheet are reported in table 2. The SD values are

considered as low for all the experimental units. IP values below 0.25,

generally signed the presence of monodisperse particle suspensions. This is the

case for the nanosuspension of particles with mean size under 300 nm. For the

samples n°2, 9 and 10, IP>0.25 signed polydispersed suspensions.

The

partial least-square process (PLS) which allows fitting the experimental

response with the analytical model and parametric analysis methods, such as

analysis of variance (ANOVA) or t-test, were based on assumptions that the

population characteristics must be drawn from normally distributed populations.

Therefore, the experimental design data distributions were examined for

departures from normality using a Shapiro-Wilk W test extended by Royston (15, 16) that thought to be one of the best tests of

normality for small data samples. The p-value=0.0120 obtained with this W test was less

than 0.05 criterion, then the hypothesis that the data

were normally distributed was rejected. The non-normal distributions of data may

be “fixed” using appropriate transformation of the size response. Box-Cox

transformation procedure (17) was

investigated to find the best transformation that will approximately normalize

the data. The best transformation indicated by the Cox-box procedure which

minimize the residual sum of squares was obtained with a Log10

transformation of the nanoparticle size (Lambda max=0, 103942).

The unknown coefficients b of the equation were

estimated with PLS, which allows fitting the transformed size response

with the analytical model. Corresponding coefficients were

replaced in the following general equation 1:

h=2,09988 - 0.133451X1 + 0.256992X2 +

0.355274X3 + 0.013582X12 + 0.0479853X23 + 0.089019X13

- 0.05337X12 - 0.0712576X22 +

0.148889X32 (2)

The correlation coefficients R2 and

R2Adjusted describe respectively the fraction of

variation of the response explained by the model and the fraction of variation

of the response explained by the model adjusted for degrees of freedom. The

coefficient of prediction Q2 describes the fraction of variation of

the response that can be predicted by the model.

Here, the

coefficient of correlation R2=0.986 and determination R2Adjusted=0.975

showed that quadratic model is well fitted by PLS. Besides, nanoparticle sizes

are well predicted as indicated by the coefficient of prediction Q2=0.879.

The summary of the analysis of variance (ANOVA) procedure based on F-test is shown in

table 3.

Table 3: Regression analysis for the nanoparticle size with quadratic response

surface model fitting. hi is the predicted response of ith

experiment, yi is the measured response of ith

experiment,  is the mean value of measured response, yi0

is the measured response of ith experiment in central positions.

is the mean value of measured response, yi0

is the measured response of ith experiment in central positions.  is the mean value of

response in central position. Variance column was the ratio of sum of squares

by the corresponding degree of freedom.

is the mean value of

response in central position. Variance column was the ratio of sum of squares

by the corresponding degree of freedom.

|

Source

|

Degree of freedom

|

Sum

of squares

|

Mean

square (variance)

|

F value

|

Probability p

|

|

Regression

|

5

|

å(hi- )2

= 1.01586 )2

= 1.01586

|

0.203172

|

87.0796*

|

0.000

|

|

Residual

|

6

|

å(yi-hi)2 = 0.013999

|

0.00233317

|

|

|

|

|

|

|

|

|

|

|

Lack

of Fit

|

5

|

å(yi-hi)2-å(yi0- )2

= 0.0138282 )2

= 0.0138282

|

0.00276564

|

16.1906**

|

0.186

|

|

Pure Error

|

1

|

å(yi0- )2

= 0.000170818 )2

= 0.000170818

|

0.00017082

|

|

|

* Significant at the level

95%; F0.05 (5, 6) = 4.39

** Significant at the level

95%; F0.05 (5, 1) =230.16

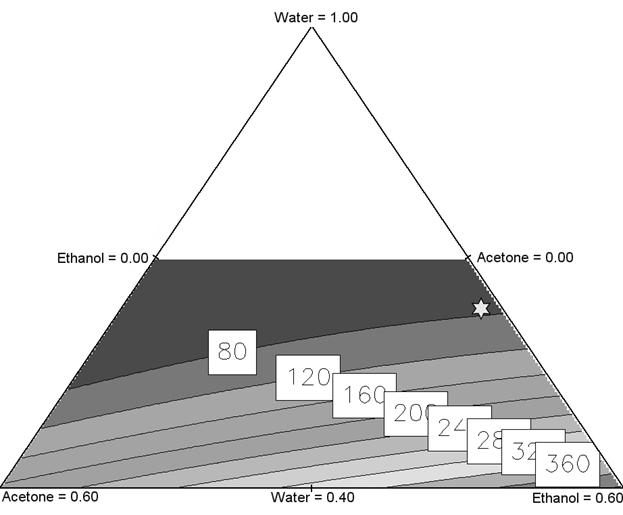

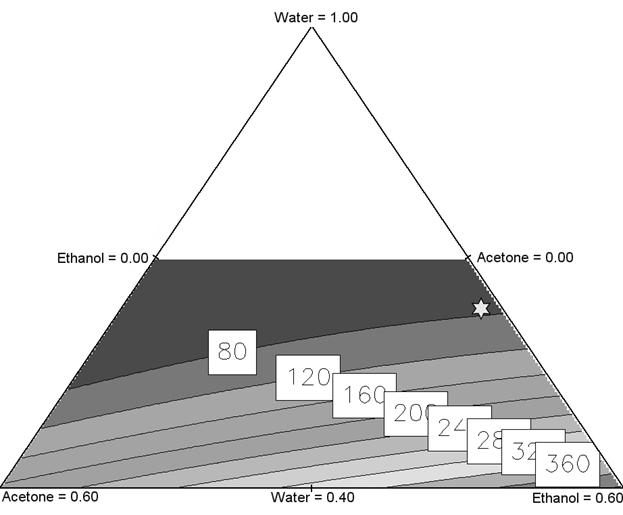

Figure 2: Ternary diagram for nanoparticle size. White star corresponding to the mixture

water/acetone/ethanol=0.64/0.01/0.34 for a size of 82 nm.

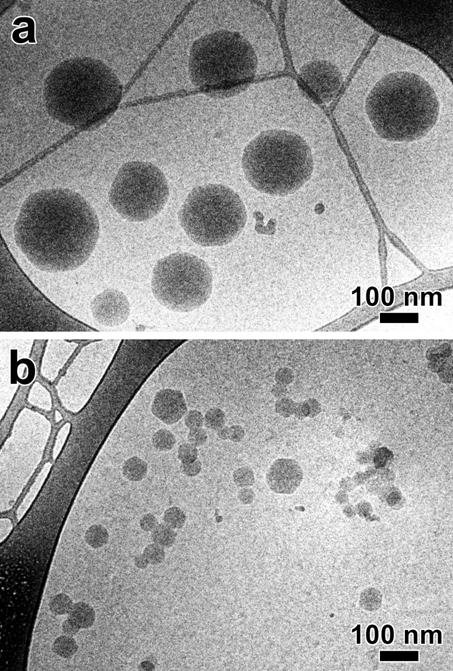

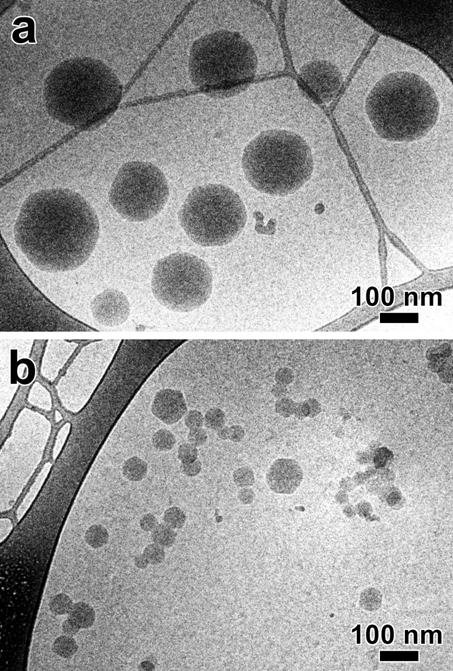

Figure 3: Cryo-TEM images of β-cyclodextrin nanoparticles

in suspensions corresponding to experiment units 9 (a) and 12 (b),

respectively.

The

probability for the model regression is significant at 95% (P-value=0.000<0.05)

and the probability for lack of fit is not significant at 95% (P-value=0.186>0.05).

Hence, the quadratic model is statistically good and has no lack of fit within

the range of variables used.

All the nanoparticles size and the

corresponding solvent mixture were plotted in a ternary diagram (figure 2)

using the equation 2. The solvent proportions were explained in percentage unit

scaled from 0 to 1 in accordance with the limits

defined in table 1. Each point of the diagram corresponds to defined

proportions of acetone, ethanol and water used in the experiment. The white

area depicted on the ternary diagram is an experimentally unexplored zone of

mixture. Each line plotting inside the diagram defines a specific size value

(nm) labelled in the white square.

In order to decrease the nanosphere size,

the nanoprecipitation should be investigated with high

amount of water and low amount of organic solvent. This plot also indicates

that the use of acetone as organic fraction is more efficient than ethanol to

obtain small nanospheres.

An experimental test point focused on interesting

mean size of 82 nm was carried out to confirm the model

validation. The procedure used to predict the corresponding experimental

conditions was the Nelder-Mead simplex method (18). The computation leads to

the optimal following mixture water/acetone/ethanol=0.6428/0.01270/0.3445

(v/v/v). The mean size of nanoparticles obtained when applying these conditions

was measured at 86 nm. This result was in accordance with

the predicted value of 82 nm in 95% confidence interval. Consequently, the

quadratic model was experimentally checked as good.

The

morphology of the colloidal nanoparticles from selected experiments was studied

by cryo-TEM.

Images

of suspensions from experimental units 9 and 12 are shown in

Figures 3a and 3b,

respectively. In both cases, the particles are uniformly dense and spheroidal,

although several of them exhibit a clear faceting. Such a faceting has already

been reported by Gèze et al. (3) for bCDa particles. Those corresponding to experimental unit 9 are

individual while some aggregation is observed in the suspension from

experimental unit 12. The diameter measured from the cryo-TEM images ranges

from 100 to 250 nm and 40 to 100 nm for particles from experimental

units 9 and 12, respectively. The cryo-TEM images leads to a diameter slightly

lower than that measured by QELS (table 2). This observation was because the

values were obtained using different calculation procedures (intensity diameter

for QELS and weight diameter for TEM); it is worth reminding that the QELS

measurement integrates the ionic environment surrounding the particle surface.

As this environment is not substantially denser than the embedding vitreous

ice, it will not be detected in cryo-TEM images.

(3)

CONCLUSION

In

conclusion, this mixture design methodology led to a significant empirical

correlation between the solvent proportion involved in amphiphilic cyclodextrin

self assembling procedure and the corresponding nanoparticle size. With the

output of this study, we are able to prepare nanoparticles with predicted mean

size varying from 60 to 400 nm. In the future, further studies will be carried out to establish the influence of the size

of nanoparticles on their drug loading capacity and to check the long-term

stability of these loaded nanoparticles.

REFERENCES

[1]

Duchêne, D.; Ponchel,

G.; Wouessidjewe, D. Cyclodextrins in targeting application to nanoparticles.

Adv Drug Deliv Rev, 36:29-40, 1999.

[2] Duchêne,

D.; Wouessidjewe, D.; Ponchel, G. Cyclodextrins and carrier systems. J Control

Release, 62:263-268, 1999.

[3] Gèze, A.;

Putaux, J. L.; Choisnard, L.; Jéhan, P.; Wouessidjewe, D. Long-term shelf

stability of amphiphilic b-cyclodextrin

nanosphere suspensions monitored by dynamic light scattering and

cryo-transmission electron microscopy. J Microencapsul, 21(6):607-613, 2004.

[4] Gèze,

A.; Aous, S.; Baussanne, I.; Putaux, J. L.; Defaye, J.; Wouessidjewe, D.

Influence of chemical structure of amphiphilic b-cyclodextrins on their ability to form stable

nanoparticles. Int J Pharm, 242:301-305, 2002.

[5] Horn,

D.; Rieger, J. Organic nanoparticles in the aqueous phase-theory, experiment,

and use. Angew Chemie Int, 40: 4330-4361, 2001.

[6] Lesieur,

S.; Charon, D.; Lesieur, P.; Ringard-Lefebvre, C.; Muguet, V.; Duchêne, D.;

Wouessidjewe, D. Phase behavior of fully hydrated DMPC-amphiphilic cyclodextrin

systems. Chem Phys Lip, 106:127-144, 2000.

[7] Dubes,

A.; Bouchu, D.; Lamartine, R.; Parrot-Lopez, H. An efficient

regio-specific synthetic route to multiply substituted acyl-sulphated b-cyclodextrins. Tetrahedron Lett,

42:9147-9151, 2001.

[8] Lamer,

V. K.; Dinegar, R. H. Theory, production and mechanism of formation of

monodispersed hydrosols. J Am Chem Soc, 72:4847-4854, 1950.

[9] Skiba,

M.; Wouessidjewe, D.; Puisieux, F.; Duchêne, D.; Gulik, A. Characterization of

amphiphilic b-cyclodextrin nanospheres. Int J Pharm,

142:121-124, 1996.

[10] Durrieu,

V.; Gandini, A.; Belcacem, M. N.; Blayo, A.; Eiselé, G.; Putaux, J. L.

Preparation of aqueous anionic poly-(urethane-urea) dispersions: influence of

the nature and proportion of the urethane groups on the dispersion and polymer

properties. J Appl Polym Sci, 94(2):700-710, 2004.

[11] DuMouchel,

W.; Bradeley, J. A simple Bayesian modification of D-optimal designs to reduce

dependence on an assumed model. Technometrics, 36:37-47, 1994.

[12] Höfle,

G.; Steglich, W.; Vorbrüggen, H. 4-dialkylaminopyridines as highly active

acylation catalysts. Angew Chem Int Ed Engl, 17:569-583, 1978.

[13] Annadurai,

G.; Sheeja, R. Y. Use of Box-Behnken design of experiments for the adsorption

of verofix red using biopolymer. Bioprocess and Biosystems Engineering,

18(6):463-466, 1998.

[14] Goupy,

J., Plans d'expériences : les mélanges. DUNOD ed., 2000.

[15] Shapiro,

S. S.; Wilk, M. B. An analysis of variance test for normality

(complete samples). Biometrika, 52:591-611, 1965.

[16] Royston,

P. An Extension of Shapiro and Wilk's W Test for Normality to

Large Samples. Applied Statistics, 31:115-124, 1982.

[17] Box, G.

E. P.; Cox, D. R. An analysis of transformations. J.

Royal Stat. Soc., 26:211-243, 1964.

[18] Nelder,

J. A.; Mear, R. A simplex method for function minimization.

Comput J, 7:308-315, 1965.

JPPS Contents

Published by the Canadian Society for

Pharmaceutical Sciences.

Copyright © 1998 by the Canadian

Society for Pharmaceutical Sciences.

http://www.cspscanada.org/

CSPS Home |

JPPS Home |

Search |

Subscribe to JPPS

![]() (1)

(1)