J Pharm Pharmaceut Sci (www.cspscanada.org) 8(2):299-315, 2005

A topical w/o/w multiple emulsions prepared with Tetronic 908 as a hydrophilic surfactant: Formulation, characterization and release study

Figen TIRNAKSIZ, Ozlem KALSIN. Gazi University Faculty of Pharmacy, Department of Pharmaceutical Technology, Etiler – 06330, Ankara, Turkey.

Corresponding author: Figen TIRNAKSIZ, Gazi University Faculty of Pharmacy, Department of Pharmaceutical Technology, Etiler – 06330, Ankara, Turkey. e-mail: feegosh@yahoo.com

Received February 14, 2005, Revised May 25, 2005, Accepted June 6, 2005, Published August 11 2005

ABSTRACT

Purpose: The aim of this

work was to prepare the stable water/oil/water multiple emulsions (MEs), to

investigate the usage of poloxamine 908, to observe the influence of surfactant

percentage on the properties of MEs. Method:

MEs were prepared by liquid paraffin, cetyl dimethicone copolyol and poloxamine

908 by a two-step emulsification procedure. Caffeine was used as a water-soluble

model. The viscosity, conductivity and globule size of MEs were followed over

time. Results: The formulations containing 1% cetyl dimethicone copolyol

and 1 or 2% poloxamine 908 were the most stable systems. The globule size of

MEs ranged from 20 to 37 µm and did not change during time. The yield of MEs was between 99.6% and 98.7%.

The conductivity increased and the viscosity of systems decreased during time.

Increase in poloxamine 908 influenced the viscosity of the system, with the

viscosity decreasing as the hydrophilic surfactant concentrations were

increased. Caffeine release from the MEs was slow; the release was affected by

both surfactant concentrations. Conclusion:

Poloxamine 908 could be used as a hydrophilic surfactant for formulation of

w/o/w MEs. The concentration of poloxamine 908 was a very important parameter

in preparing stable MEs. It was

concluded that caffeine might be transported out by molecular diffusion and

through a reverse micellar mechanism controlled by the viscosity of the system

INTRODUCTION

Multiple emulsions are vesicular and

complex systems [1]. They can be considered as emulsions of emulsions and have

shown promise in cosmetic [2, 3], pharmaceutical and separation sciences [4].

Their potential pharmaceutical applications

include uses such as taste masking, adjuvant vaccines, an immobilization of

enzymes and sorbent reservoir of overdose treatments, and for enhancement of

enteral or dermal absorption [5-8]. Multiple emulsions have been formulated as

cosmetics, such as skin moisturizer [9]. Prolonged release can also be obtained

by means of multiple structures [10-13]. These systems have some advantages,

such as the protection of the entrapped substances [14, 15] and the

incorporation of several actives in the different compartments [16]. Despite

their potential usefulness, applications of multiple emulsions have been

limited because of thermodynamic instability and their complex structure.

Water/oil/water (w/o/w) multiple emulsions

consist of dispersed oil globules containing smaller aqueous droplets; each

inner aqueous droplet is separated from the outer aqueous phase by an oil phase

layer. The presence of at least two surfactants is required. One of them is

predominantly lipophilic for stabilizing the primary water/oil (w/o) emulsion

and the other is hydrophilic for the secondary oil/water emulsion. To produce a

w/o/w emulsion, the lipophilic and hydrophilic surfactants are dissolved in oil

and continuous aqueous phase, respectively. The most common preparations of

w/o/w double emulsions are based on the two-step emulsification process. The

stability and release characteristics of multiple emulsions are influenced by

different factors, such as surfactant type, surfactant ratio and some physical

properties of the system (globule size, viscosity, conductivity, phase volume

ratio, etc) [1, 17, 18].

The Poloxamine 908 (Tetronic®908)

used in this study as a hydrophilic surfactant is nonionic and a block

copolymer [19]. We could not find any published work on the usage of the

Tetronic®908 in the formulation of multiple emulsions. Cetyl

dimethicone copolyol (Abil®EM90) used as a lipophilic surfactant is

the siliconic polymeric surfactant, and shows good trapping capacity, prolongs

the release of active molecules, and produces a w/o emulsion with strong

interfacial film [4, 20, 21].

The purposes of this research were i) to investigate the usage of Tetronic®908

for w/o/w multiple emulsion formulation, ii)

to evaluate the formation and stability of the multiple emulsion system, iii) to investigate the properties of the

system and to observe the influence of hydrophilic and lipophilic surfactant

percentage on the characteristic properties of multiple emulsions.

EXPERIMENTAL

Chemicals

The following substances were used for the

preparation of multiple w/o/w emulsions: The oil used was liquid paraffin

(η: 110-230 mPa.s, Merck). Abil®EM90

(cetyl dimethicone copolyol,

Caffeine (Merck) frequently used in

cosmetic products was selected as a hydrophilic model substance for release

experiment. Sodium chloride (NaCl) was incorporated into the aqueous internal

phase and used as a conductimetric tracer.

All materials were of analytical grade and

used without further purification.

Preparation

of w/o/w multiple emulsion

Multiple emulsions were prepared by a

two-step emulsification process [2]. The first emulsification was to prepare

the w/o primary emulsion and the second emulsification step provided the

formation of the w/o/w multiple globules. The compositions of formulations are

shown in Table 1.

Electrolyte or both electrolyte and

caffeine were dissolved merely in the aqueous phase of the primary w/o

emulsion. The osmotic pressure of the internal aqueous phase of multiple

emulsions containing or not-containing caffeine was adjusted to 3.4 atm.

The concentrations of paraffin oil and

electrolyte in primary emulsions were fixed at 30 and 0.3%, respectively. The

percentage of the primary emulsion was also constant at 80%.

|

Table 1: Composition of the w/o/w multiple emulsions |

|

|

First emulsification (for primary w/o emulsion) |

|

|

Without caffeine Oil phase |

|

|

Liquid paraffin |

30% |

|

Abil®EM90 |

2 or 4% |

|

Internal aqueous phase |

|

|

Sodium chloride |

0.3% |

|

Distilled water to |

100 |

|

With caffeine Oil phase |

|

|

Liquid paraffin |

30% |

|

Abil®EM90 |

2 or 4% |

|

Internal aqueous phase |

|

|

Sodium chloride |

0.03% |

|

Caffeine |

1.5% |

|

Distilled water to |

100 |

|

Second emulsification (for w/o/w multiple emulsion)* |

|

|

Oil phase |

|

|

Primary w/o emulsion |

80% |

|

External aqueous phase |

|

|

Tetronic®908 |

1, 2 or 4% |

|

Distilled water to |

100 |

|

*The caffeine concentration

of multiple emulsions = 1.2% |

|

Water/oil primary emulsions were prepared

with different concentration of a lipophilic surfactant (Abil®EM90). Two concentration of

Abil®EM90 were used in

the primary emulsion (2 and 4%). The oily mixture of Abil®EM90 and paraffin was heated to 75oC and

then aqueous solution at the same temperature was added to this mixture by

stirring at 1500 rpm at 75 oC for 30 minutes. The first step was

carried out using the mechanical mixer to produce fine droplets. The emulsion

prepared was then cooled to room temperature. The mixer used to prepare the MEs

was the similar of Microvortex mechanical mixer (Granier Charvet SA, France)

and it was produced in

The stability of the w/o primary emulsion

prepared at the first emulsification was an important factor determining the

stability of the w/o/w emulsion. Therefore, the accelerated physical stability

of primary emulsions was tested under centrifugation (Mechanica Precyzynjna,

Warszawa, MPW-340, Poland) during 1 hour at 3500 rpm (10060 m/s2 or

1026 g), and the occurrence of phase

separation was examined. The stability of w/o emulsions under centrifugation

reflects the strength of the interfacial film between the aqueous and oil

phases. No change was macroscopically observed in any of the primary emulsions

in this study, which were quite stable. Moreover, no phase separation was

observed during 6 months at room temperature.

Water/oil/water multiple emulsions

containing caffeine were prepared by the same emulsification procedure under

the same conditions. Both caffeine and NaCl were dissolved into the inner

aqueous phase. The osmotic pressure created by adding caffeine was calculated

according to Van’t Hoff’s equation, and NaCl concentration was decreased to

equilibrate the osmotic pressure increased by the presence of caffeine in the

internal droplets.

For the preparation of the w/o/w multiple

emulsion, the freshly prepared w/o primary emulsion (80g) was emulsified

further in an external aqueous phase (20 g) inside which the hydrophilic

surfactant was dissolved at room temperature. The mixture (100 g) was stirred

using mechanical mixer at

The formation times of multiple globules

were determined, and this experiment was done with multiple emulsions

containing caffeine. The caffeine concentration of MEs was 1.2%.

Characteristics

of multiple emulsions

After preparation of the multiple emulsions

not containing caffeine, several physical tests were carried out in order to

determine their characteristics, such as viscosity, mean multiple globule size

and conductivity.

In this study, the physical stability of

w/o/w multiple emulsions prepared was also examined using viscometric,

conductimetric and granulometric methods. In addition, formulations were

evaluated by visual observation of the phase separation. Macroscopic analysis

was carried out to observe the homogeneity of the systems.

The multiple emulsions were stored at 25

and 40 oC, and the characteristic properties of the systems

were followed until phase separation was observed. At a definite time, the

emulsions were allowed to return to room temperature before observation, and

then the viscosity, mean multiple globule size and conductivity values were

determined.

The data were evaluated by statistical

analysis according to the Student’s-t test. In addition, standard error (SE)

was computed for every mean value.

Microscopic

analysis, measurement of globule and droplet size

Microscopic analysis was carried out using

an optical immersion microscope (Soif, Model 4GX, AN-KA, Istanbul-Turkey), and

observations were made at 100x16 magnification after diluting in the

appropriate external phase of emulsion. This examination provided direct

information on the multiple structures.

We could see the internal aqueous phases as droplets in a w/o/w emulsion

structure. The existence of multiple

globules was checked microscopically during all experiments until the phase

separation was observed.

Granulometric analysis was carried out in

order to characterize the globule size of multiple emulsions and the droplet

size of w/o primary emulsion. The mean size of dispersion phase for every

emulsion was determined with a laser diffraction particle sizer (Sympatec GmbH,

HELOS Particle Size Analysis,

|

Table 2: Main properties of multiple emulsions

after immediately preparation |

||||

|

Abil

EM90 |

Tetronic

908 |

Viscosity* at 5 rpm (mPa.s) |

Globule

size (µm) |

Conductivity (µS) |

|

2% |

1% |

60000 |

20.6 |

21.3 |

|

2% |

2% |

58000 |

20.6 |

26.8 |

|

2% |

4% |

46000 |

34.6 |

28.4 |

|

4% |

1% |

60000 |

29.5 |

28.9 |

|

4% |

2% |

54000 |

30.2 |

53.9 |

|

4% |

4% |

44000 |

36.8 |

64.0 |

|

|

|

|

|

|

Measurement

of viscosity

For the viscometric measurements, the

samples of multiple emulsions were examined using Brookfield LV rotational

viscometer (Brookfield Engineering Lab. Inc. MA,

Conductimetric

analysis

The conductivity was measured with

conductimeter (HI-9033, Hanna Inst.). It was necessary to dilute multiple

emulsions with water or iso-osmotic NaCl solution to measure conductivity. The

preliminary studies were performed to establish whether further dilution could

influence the measurement. The measurements were made at room temperature on

samples of the multiple emulsion diluted

The entrapment percent or yield value (E%) was calculated according to the following

equation:

E%=

![]()

where Ci

is the conductivity of the internal aqueous phase (0.3% NaCl solution, 4800 µS)

and Ct is the conductivity

value of multiple emulsion at a given time t.

In

vitro release studies

Release study of caffeine from multiple

emulsions was investigated by a dialysis method. Before this experiment, the

saturation solubility of caffeine in buffer solution (pH 5.2) at 32 oC

was determined in triplicate. An excess amount of caffeine was added into

Dialysis tubing (seamless, D-0405,

lot:01H0713, Sigma) was used as a membrane for the release study and was washed

several times with distilled water and left soaking in buffer solution (pH 5.2)

overnight before use. Immediately after preparation, 2 g of the multiple

emulsions containing 1.2% caffeine was introduced into the dialysis tubing

double-tied at each end and dialyzed in

RESULTS

and DISCUSSION

In the development of w/o/w multiple

emulsions, it is necessary to estimate their physical stability experimentally.

Viscosity, multiple globule size and conductivity measurements are convenient

methods for this purpose [22].

In this study, we tried to formulate a

stable multiple emulsion with Tetronic®908 in the external phase as

the hydrophilic surfactant and with Abil®EM90 in the inner aqueous

phase as the hydrophobic surfactant. Two different concentrations of the

lipophilic surfactant and three different concentrations of the hydrophilic

surfactant were used in order to evaluate the influence of the surfactant

percentage on the characteristics of multiple emulsions (Table 1).

It was shown that the stability of the w/o

emulsion requires the presence of electrolyte in the aqueous phase; it is well

known that the electrolyte concentration or osmotic pressure of the internal

aqueous phase of w/o/w emulsions plays a critical role in the physical

stability of the system [23]. Thus, the optimum balance should be ensured

between the internal and external aqueous phase of w/o/w multiple emulsions

[24, 25]. Therefore, we examined the literature regarding the formulation of

w/o/w multiple emulsions, and it was decided to use NaCl at a concentration of

0.3% (0.0513 molar) as electrolyte [26].

Viscosity, mean globule size and

conductivity were determined to investigate the characteristics of multiple

emulsions not containing caffeine as a function of time. Measurements were made

up to five months at monthly intervals following preparation of the emulsions.

In addition, phase separation and phase inversion of multiple emulsions were

also investigated, and the results of visual observations are summarized in

Table 3. The beginning of phase separation is shown, which revealed a

destruction of multiple globules of the system. During storage time, no phase

inversion was observed in any multiple emulsions.

It is well known that coalescence is

amplified with temperature. In this study, the beginning of phase separation at

40 oC occurred earlier than at 25 oC, except for

formulations containing 4% Abil®EM90. For example, phase separation

was observed at the fourth month for the multiple emulsion containing 2% Abil®EM90

at 40 oC, whereas phase separation was observed at the fifth month

at 25 oC.

When the physical stability of multiple

emulsions containing varying amounts of Tetronic®908 and a constant

of Abil®EM90 was evaluated, it was observed that the stability

decreased as Tetronic®908 concentration increased. At high Tetronic®908 concentration (4%) coalescence occurred, resulting in

phase separation within three or four months. On the contrary, no phase

separation or physical stability problem occurred over five months at 25oC

for multiple emulsions with prepared lower concentrations of Tetronic®908

(1 and 2%). A similar finding was reported in other investigations [27-31].

Matsumota et al. [27] explained the effect of an increase in the amount of

hydrophilic surfactant on the physical stability of multiple emulsions as: During

the second emulsification, some of the molecules of the hydrophobic surfactant

from the oil layer may be solubilized in the external aqueous phase due to

amount of hydrophilic surfactant that is above critical concentration. This

phenomenon may be a very important cause of the rupture of the oil layer

covering the internal aqueous phase droplets after preparation of the system.

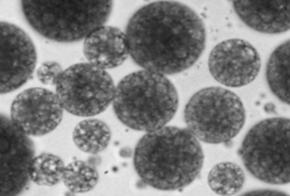

Microscopic

and globule size analysis

Microscopic technique is the useful direct

method to assess the formation and to follow the stability of multiple

globules. The various stability problems, such as globule deformation and phase

inversion to simple emulsion, may be detected using this method.

All multiple emulsions were prepared

successfully using the method described. The structure of w/o/w multiple

emulsions was observed under the microscope during

manufacturing. Many multiple globules were observed very well and many small

droplets were seen in the internal phase of multiple globules. The microscopic

view of a multiple emulsion is shown in Figure 1.

Figure

1: Microscopic view of multiple emulsion (100x16 magnification).

To evaluate the type of multiple emulsions,

a drop of a water-soluble dye (methylene blue) solution was added to the system

and dissolution of dye solution was observed. The colored mixture was then

examined by optical microscopy. This procedure revealed that water was the

continuous phase and that the sample was a w/o/w emulsion.

The size of globules is the most important

parameter in rheology and physical stability of any emulsion. The globule size

of multiple emulsions as a function of time is shown in Figure 2. When change in multiple globule size was investigated, no

significant increase or decrease was observed in the mean size during storage

time at 25 and 40 oC; this may not be evidence of non-coalescence. A similar result was also reported by

Figure

2: Globule size of multiple emulsions as a

function of time

Figure

3: Effect of temperature on conductivity of w/o/w

multiple emulsions during storage time

The mean multiple globule sizes of

emulsions were recorded in the range of 20±0.025 µm and 37±0.031 µm (mean±confidence interval). In our previous study, the particle

size measurements of w/o primary emulsions demonstrated a mean droplet size

(±CI) of the aqueous phase, 3.38±0.0216 µm and 3.44±0.0541 µm for emulsions

prepared with 2% Abil®EM90 and 4% Abil®EM90, respectively

[34]. These values were statistically the same (p>0.05). This result showed that

there was no significant effect of high lipophilic amount (4%) on the

interfacial tension between water and oil phase; the effective reduction of

interfacial tension was probably ensured by 2% of Abil®EM90. The

globule size of primary emulsions did not change, and no visual sign of

physical destabilization was observed in systems at 25 and 45 oC

during storage time.

As expected, the mean globule size of

multiple emulsions depended on the surfactant concentrations.

When the effect of Tetronic®908

concentration on globule size of multiple emulsions was investigated, a small

increase with increasing surfactant amount was observed; the higher

concentration of hydrophilic surfactant most likely caused the coalescence of

globules due to rupture of oil layer between two aqueous phases during

manufacturing [27]. However, there was no significant effect of Tetronic®908

concentration (for low concentration, 1 and 2%) on globule size of multiple

emulsions containing the same percentage of Abil®EM90 (Table 2)

(p>0.05).

When the percentage of Abil®EM90

was increased from 2% to 4%, the globule size logically increased. The excess

of Abil®EM90 was located in a molecular form in the oil phase

between external and internal aqueous phase, and this caused swelling of the

oil globules (Table 2). On the contrary, the globule size of multiple emulsions

containing caffeine decreased with increasing Abil®EM90 percentage

and the same concentration of hydrophilic surfactant (Table 4). It was

concluded that caffeine influenced the tension of the second interface during

the second emulsification step.

Conductimetric analysis

This analysis was carried out in order to

directly measure the entrapped electrolyte within the internal aqueous phase

and to confirm the emulsion type. Conductivity data generated good information

about the emulsion type. Both dying method and low positive conductivity values

demonstrated the w/o/w type emulsion.

Multiple emulsions yielded low conductivity

values immediately after preparation of formulations. The yield of the

emulsions (entrapment percent, E%) was between 99.6% and 98.7%,

meaning that a portion of the NaCl in the inner aqueous phase, approximately

between 0.4% and 1.3%, leaked into the external aqueous phase during the

preparation of multiple emulsions.

Although the yield values were high,

unfortunately phase separation was observed in some formulations during storage

time at 25 and 40 oC (Table 3).

During storage of w/o/w emulsions, the

conductivity values increased with time (Figure 3). The increase in

conductivity during storage time can be ascribed to the increase in NaCl in the

external aqueous phase due to i) a

diffusion of NaCl through the mineral oil film [35] or ii) the coalescence of internal and external aqueous phases [36], destruction

of oil film because of osmotic pressure and then expulsion of internal aqueous

phase. This most likely explains the

phase separation observed in this study. Due to rising conductivity, declining

viscosity and the approximately stable globule size of multiple emulsions

during storage time, it was concluded that the solute and water molecules were

transported from the oil membrane by a diffusional mechanism.

|

Table 3: Effect of surfactant concentration on

physical stability of multiple emulsions

|

|||||||

|

Abil®EM90 |

Tetronic®908 |

1 month |

2 months |

3 months |

4 months |

5 months |

|

|

2% |

1% |

_ |

_ |

_ |

_ |

no PS

PS at 40o |

|

|

2% |

2% |

_ |

_ |

_ |

no PS at 25o PS at 40o

|

no PS at 25o PS at 40o |

|

|

2% |

4% |

_ |

_ |

_ |

no PS at 25o PS at 40o |

PS at 25o PS at 40o |

|

|

4% |

1% |

_ |

_ |

_ |

_ |

PS at 25o PS at 40o |

|

|

4% |

2% |

_ |

_ |

_ |

PS at 25o PS at 40o |

PS at 25o PS at 40o |

|

|

4% |

4% |

_ |

_ |

PS at 25o PS at 40o |

PS at 25o PS at 40o |

PS at 25o PS at 40o |

|

|

‘―‘

indicates phase separation neither at 25 oC nor at 40 oC;

PS, phase separation |

|||||||

The conductivity profiles showed that the

transport rate of NaCl molecules from inner to outer aqueous phase decreased

with time (first order kinetics) (Figure 3). The cause for the decreasing rate

was interpreted as: The inner aqueous droplets of w/o/w emulsions probably grow

with time due to coalescence of smaller droplets because of the higher

percentage of hydrophilic surfactant. However, in this study, the volume of the

oil phase was constant, and therefore the oil layer covering inner

growing aqueous droplets thickened. Thus, the thickened layer delayed

the transport of electrolyte molecules.

The temperature accelerated the diffusion

or transport of NaCl molecules from inner to external aqueous phase. The

calculated conductivity rate constants (ℓn µS/month) were significantly

different when compared with the formulations having the same composition at 25

or 40 oC (p<0.05). For example, the conductivity rate constants

of multiple emulsions containing 1% Tetronic®908 and 2% Abil®EM90

were calculated as 0.229±0.0183 ℓn µS/month and 0.339±0.03 ℓn

µS/month at 25 and 40 oC, respectively.

The effect of Abil®EM90

concentration on conductivity of the system was investigated, and no

significant difference was obtained among formulations containing 1% Tetronic®908.

Conductivity values were similar with 2 or 4% Abil®EM90

concentration at 25oC. At higher concentrations of Tetronic®908

(2 and 4%), the two-fold increase in lipophilic surfactant did not hinder the

increase in conductivity (Figure 3). Unfortunately, the increase in

concentration of lipophilic surfactant could not provide the physical stability

of the system (Table 3). This finding was in contrast with previous literature

[27, 37, 38].

There was a direct relationship between the

percentage of Tetronic®908 and the conductivity of multiple

emulsions. As could be seen in Figure 3, the conductivity of systems containing

the same amount of lipophilic surfactant increased with increasing Tetronic®908

concentration. This result was also observed by the other investigators [27,

31, 37, 38]. As mentioned previously, the excess

amount of Tetronic®908 in the external aqueous phase probably caused

the formation of micelles and then the solubilizing of Abil®EM90 molecules, thus weakening or rendering unstable

the interface of the w/o system. Therefore, NaCl molecules migrated more easily

from the internal to external aqueous phase.

Viscometric

analysis

Measurement of viscosity gives us useful

data, especially in quality assurance of emulsions. The variation in viscosity

of systems may explain some differences between formulations and at the same

time provide important information about coalescence or globule size change.

The viscosity of the w/o/w multiple

emulsions was measured at four different rpm to follow the time dependence of

viscosity. The viscosity values only at 5 rpm were selected for tables and

figures.

The viscosities of emulsions at first day

after preparation are shown in Table 2.

There are many factors affecting the

viscosity of multiple emulsions; one is the multiple globule size. There was a

direct relationship between the viscosity and globule size of multiple

emulsions. As expected, the minimum

viscosity was observed with the higher globule size (Figure 4). Higher

viscosity may be attributed to the small globule size of multiple emulsions

prepared with the same concentration of Abil®EM90.

Increased hydrophilic surfactant influenced

the viscosity of system, with the viscosity decreasing as the Tetronic®908

concentrations were increased (Table 2), whereas no significant difference in

viscosity as a function of Abil®EM90 percentage was observed

(p>0.05).

All the multiple emulsions exhibited

non-newtonian flow and shear thinning behavior. It means the viscosity of

system decreased with increasing shear stress. The viscosity of multiple

emulsions reduced with increasing shear stress from 5 rpm to 20 rpm. Only one

example of the plots of viscosity versus shear stress (rpm) is shown (Figure

5). In some literatures, the bursting of

multiple globules [39, 40] or phase inversion under shear stress [41] have been

shown, but we did not observe any destruction of multiple globules or phase

inversion after viscosity measurement using optical microscopy. It was

concluded that shear stress used in this study did not induce irreversible

structural changes in multiple emulsions, such as coalescence or phase

inversion.

|

Table 4: Release rate constant of caffeine and some

physical characteristics of multiple emulsions containing caffeine |

||||||||||

|

|

2%

Abil EM90 |

4%

Abil EM90 |

||||||||

|

Tetronic 908, % |

1% |

2% |

4% |

1% |

2% |

4% |

||||

|

kro |

2.31 |

2.89 |

5.66 |

2.56 |

3.82 |

6.95 |

||||

|

(Released %/hour)a |

(0.369)b |

(0.496)b |

(0.511)b |

(0.198)b |

(0.331)b |

(0.552)b |

||||

|

Viscosity (mPa.s) |

54000 |

32000 |

30000 |

56000 |

48000 |

32000 |

||||

|

Globule size (µM) |

25.5 |

34.6 |

36.6 |

19.6 |

20.6 |

35.8 |

||||

|

Released % (±SD)c |

14.8 |

15.9 |

18.3 |

17.2 |

19.0 |

30.9 |

||||

|

(at first two hours) |

(±1.17)c |

(±1.55)c |

(±0.673)c |

(±0.708)c |

(±0.154)c |

(±1.76)c |

||||

|

Released % (±SD) |

26.3 |

26.8 |

41.1 |

26.4 |

27.6 |

54.2 |

||||

|

(at 6th hours) |

(±1.09) |

(±1.09) |

(±1.00) |

(±0.462) |

(±1.51) |

(±0.905) |

||||

|

a r2≥0.997, b SE of regression, c

±standard dev., n=3 |

||||||||||

|

Table 5: Calculated parameters of the kinetic

model suggested by Magdassi and Garti (54) for release of drug from multiple

droplets |

||||||

|

2%

Abil®EM90 |

4% Abil®EM90 |

|||||

|

Tetronic®908 |

1% |

2% |

4% |

1% |

2% |

4% |

|

Slope |

0.00211 |

0.00234 |

0.00714 |

0.00198 |

0.00330 |

0.0123 |

|

Intercept |

0.000205 |

-0.000796 |

-0.00978 |

0.00127 |

-0.00297 |

-0.00839 |

|

r2 |

0.993 |

0.998 |

0.978 |

0.998 |

0.978 |

0.989 |

|

Slope= |

||||||

Viscosities of all the multiple emulsions

decreased continuously during storage with time (Figure 6). This may be due to i) diffusion of water molecules from the

inner to the outer aqueous phase and then the volume decrease of globules in

the w/o/w emulsions, or ii) bursting

of multiple globules due to osmotic pressure. When all multiple emulsions were

compared considering phase separation at 25 oC, systems containing

2% Abil®EM90 and 1 or 2% Tetronic®908 were stable at

least five months, although increasing conductivity and decreasing viscosity

with time were observed. In these formulations, water molecules probably

migrated through the liquid paraffin layer without affecting the entirety of

multiple globules. This has been described by i) micellar transport mechanism, ii) the hydrated surfactant mechanism or iii) diffusion of water molecules across the oil layer between

internal and external aqueous phase [4, 17, 28, 36, 42, 43].

Formation time of multiple globules

The effect of surfactant concentration on

formation time of multiple globules is shown in Figure 7. As can be seen, the

required formation time of multiple emulsions prepared with 2% Abil®EM90

was similar with multiple emulsions prepared with 4% Abil®EM90 for

the same concentration of Tetronic®908. In contrast, the formation

time was significantly affected by the percentage of Tetronic®908; the formation time of

multiple globules increased with an increase in hydrophilic surfactant. It was

considered that Tetronic®908

may influence the interphase between the external aqueous phase and oil layer

(or oil lamella), which has been described by Garti [17]. Abil®EM90

was probably solubilized via the micelles formed by part of the Tetronic

molecules. Thus, as Tetronic concentration increased, formation of multiple

globules was delayed; the higher the Tetronic concentration, the longer the

formation time.

Figure

4: Effect of surfactant

concentration on globule size and viscosity of multiple emulsions.

In

vitro release studies

To investigate the release characteristics

of multiple emulsions, caffeine was used as the model solute. When caffeine was

introduced in the internal aqueous phase of multiple emulsions, the viscosity

and multiple globule size of emulsions changed (Table 4).

The solubility of caffeine was found to be

20.4±0.93 mg/mL (saturation value, Cs) (pH: 5.2). That result agrees

with those of Clément et al. [44] who found that the solubility of caffeine was

19.64±0.59 mg/mL at pH: 7.4.

During release experiments, the release

rate should not be influenced by the concentration gradient between the caffeine

concentration of release medium (Crm) and the saturation

concentration of caffeine (Cs) in release medium. If the Crm

is less than or equal to “Cs x 10/100” for every sampling time, it

is said that a sink condition is maintained. So, when we used 300 ml of release

medium, even if all of the caffeine (0.024 g) in two grams of ME released, Crm

could not be higher than “Cs x 10/100” value (=20.4 x 10/100= 2.04

mg/ml). Therefore, it was concluded that the volume of dialysis medium was not

rate limiting in diffusion of caffeine and the release experiments were

conducted under sink conditions.

Figure

5: Viscosity as a function

of shear stress – Non-Newtonian flow behavior of multiple emulsion

containing 2% Abil®EM90 and 2% Tetronic®908

The cumulative percent release of caffeine

from multiple emulsions is shown in Figures 8 and 9. Points and bars in each

figure represent mean value ±standard error (SE). When the SE was smaller than

the size of symbol, no bar was shown.

All release profiles exhibited an initial

rapid release phase and then a slower release of molecules. First phase of

release profiles (the first hour of profile) might be due to caffeine existence

in the external aqueous phase during the manufacturing; during the second

emulsification, caffeine molecules probably leaked out of the internal aqueous

phase. Therefore, the secondary emulsification was stopped immediately after

observation of multiple globules on microscope.

The drug molecules at the external aqueous phase were free molecules

that were released immediately. The release of caffeine in the external phase

of w/o/w emulsions was completed within approximately 2 hours. Negligible drug

release from multiple emulsions was observed between the 1st and 2nd

hours. This may be attributed to the slow transport of caffeine from the

internal aqueous phase; a period of time was probably required for caffeine

molecules to transport from internal droplets to the dialysis membrane.

Figure

6: The decreasing of viscosity

as a function of time at 25 and 40oC (shear stress: 5 rpm)

After 2 hours, caffeine in the internal

aqueous phase was released slowly at a rate governed by the interphase barrier

between the inner and outer aqueous phases because the hydrophilic drug

molecules could not pass freely through the oily layer. So the second phase

might be attributed to a prolonged release of caffeine from the internal

aqueous phase.

The release rates presented in Table 4 were

determined from slopes of the release percentage versus time between the 2nd

and 6th hours. These rates were used the explanation and comparison

of the effect of surfactant concentration on the release profiles.

Figure

7: Effect of surfactant

concentration on formation time of multiple globules.

The

effect of hydrophilic surfactant concentration

Profiles shown in Figures 8 and 9 indicate

that emulsions containing 4% Tetronic®908 enhanced the drug released

in comparison with the other concentration of this surfactant. It was also

observed that multiple emulsions containing 1 or 2% of Tetronic®908

gave almost similar patterns of caffeine levels. When the release percentages at the end of

the release experiment were compared, the difference between values was not

very pronounced, except for the emulsions containing 4% Tetronic®908. In fact, the release percentages of caffeine

from formulations containing 1 or 2% Tetronic®908 after 6 hours were not significantly different

(p=0.849). On the contrary, when the release percentages for multiple emulsions

prepared with 4% Tetronic®908

were compared after 6 hours, the difference was statistically significant

(p=0.0297), 41.1 and 54.2% of the total dose. When we used the ANOVA, it was

found that there was the significant difference between the release rates of

MEs containing different amount of hydrophilic surfactant (p=0.017).

Although the release rate or release % of

caffeine for formulation containing 4% Tetronic®908 was relatively large, the physical stability of

those emulsions was not better than the other MEs containing 1% or 2% Tetronic®908 as shown in Table 3;

the high concentration of hydrophilic surfactant did not improve the physical

stability of system. This finding agrees with those of Matsumoto et al. [27]

and Jiao and Burgess [31]. These authors suggested that the usage of a high

concentration of hydrophilic surfactant caused the solubilization of lipophilic

surfactant and then disruption of multiple globules. In our study, the higher

concentration of Tetronic®908 in the outer aqueous phase may have

served to solubilize the molecules of the lipophilic surfactant, which probably

led to the rupture of the oil layer and then the rapid release of molecules of

caffeine to the external aqueous phase. In addition, this situation probably

caused the phase separation.

In this study, Tetronic®908 was

used in concentrations of 1, 2 and 4%, and these percentages are much higher

than critical micelle concentration defined by Atwood et al. [45] and Dong et

al. [46], 0.020% at 40 oC and 0.16% at 25 oC,

respectively. Therefore, Tetronic®908 chains probably formed

micelles in both aqueous and oil phases and this facilitated the transport of

caffeine molecules through the oil phase, as described Omotosho et al [47].

Figure

8: Release profiles of

caffeine from w/o/w multiple emulsions containing different concentration of

Tetronic®908 (mean±SE, n: 3)

The

effect of lipophilic surfactant concentration

Previous literatures have shown that the

percentage of the lipophilic surfactant plays an important role in the release

amount of active molecule. In some of these reports, when the lipophilic

surfactant concentration was increased, the release of solute molecules

decreased due to maximum viscosity of the system. The cause of increasing

viscosity has been explained as the maximum swelling of multiple globules of

the system [37, 48-51]. In contrast, in other reports, an increase in

lipophilic surfactant amount caused an increase in the release rate of solute

and water [17, 47, 52, 53]. This has been explained by

the authors as follows: During the first emulsification, the reverse micelles

form in the oil phase of w/o primary emulsion due to the higher concentration

of lipophilic surfactant that is above critical value. In addition, during the

second emulsification, the existence of hydrophilic surfactant may cause the

formation of mixed inverse micelles. Thus, both water and water-soluble

molecules in the micelles could be easily carried across the oil layer between

the internal and external aqueous phase of w/o/w emulsion.

Figure

9: Release profiles of

caffeine from w/o/w multiple emulsions containing different concentration of

Tetronic®908 (mean±SE, n: 3).

In this study, the effect of Abil®EM90

concentration on the release rate or release amount of caffeine is shown in

Table 4. It can be seen that as the concentration of lipophilic surfactant in

the primary emulsion (w/o) increased, the release rate of caffeine from

multiple emulsions increased. In

addition, the percentage of caffeine released from multiple emulsions

containing 4% Abil®EM90

was greater than that of the other multiple emulsions containing 2% Abil®EM90 prepared with same

concentration of hydrophilic surfactant. The release rates of MEs containing 2%

of lipophilic surfactant were compared to the release rates of MEs containing

4% of lipophilic surfactant using ANOVA test. It was found that the difference

was not statistically significant (p=0.114).

In our study, the droplet size of w/o

primary emulsion was approximately the same for two concentrations of Abil®EM90, which likely indicates

that the two-fold increase of lipophilic surfactant no longer significantly

decreased the interfacial tension. Thus, it is plausible to assume that a

concentration of 2% Abil®EM90

was just sufficient to cover the inner aqueous phase of the primary emulsion;

the excess amount was likely located in a molecular and micellar form

(containing water, caffeine and NaCl) in the oily phase of the primary

emulsion. So, when a higher concentration of Abil®EM90 is used in multiple emulsions, caffeine molecules

in the inner aqueous phase may be transported by micelles in addition to the

molecular diffusion.

The release studies showed that the release

rate of caffeine was faster for those systems with lower viscosity at the same

percentage of Abil®EM90;

this also depended on increasing Tetronic®908

concentrations. The viscosity of systems was more effectual than the globule

size of multiple emulsions, because emulsions with smaller globules were unable

to generate the faster release rate. Therefore, although the globule size did

not affect the rate of drug released, the viscosity of multiple emulsions did

due to consistency of the system.

Based on results of release experiments, it

was concluded that caffeine might be transported out by molecular diffusion and

through a reverse micellar mechanism controlled by the viscosity of the

system.

The

possible kinetic model for release of caffeine from multiple droplets

In the previous studies, Higuchi’s

mechanism for release of molecule from dispersed polymeric matrix was modified

and adapted for MEs [16, 53, 54]. Magdassi and Garti

applied this model to w/o/w type of MEs and defined the following equation

[54]:

![]()

where F is the fraction of the drug release from

globule; D is the diffusion coefficient of drug through oil membrane; Cs is the drug solubility in

the oil membrane between the inner aqueous phase and the outer aqueous phase; ro is the radius of the mean

globule size of ME; Co is

the initial concentration of the drug. For simplification the value of “![]() “ was called B.

“ was called B.

In our study, we used this equation and the

calculated B values were plotted

against time, t (Figure 10). The

caffeine solubility in the paraffin film and “D” value were assumed to be

constant. The swelling of the globules of MEs was also cancelled, because as

mentioned before the mean size of multiple globules was not changed during time

(Figure 2).

As shown in Figure 10, the profiles

exhibited two phase for all the MEs. This was the unexpected situation; the

relationship between B and t could be the linear. Sela et al [53]

explained the first phase of profile as resulting from the time required for

the formation of reverse micelles and solubilization of water and drug in these

micelles. The second and linear phase was the straight line as expected; this

confirmed the validity of the equation and the r2 values was higher

than 0.978 (Table 5). As a result, it

can be concluded that the release of the caffeine molecules through the

paraffin film probably was controlled by diffusion mechanism.

Figure

10: B versus t profiles for

release of caffeine from multiple droplets

CONCLUSIONS

The investigations presented lead us to

conclude that the multiple emulsions prepared with Tetronic®908 were highly uniform and high yields of w/o/w

multiple emulsions were obtained. Relatively stable systems were formed using

Tetronic®908 and Abil®EM90 surfactant pair. It is

possible to formulate an optimal multiple emulsions consisting of Tetronic®908 (1%) in the outer

aqueous phase and Abil®EM90

(2%) in the oil phase. The results

indicated that Tetronic®908

as hydrophilic surfactant might be good emulsifier for the preparation of w/o/w

type emulsions. Stability measurements showed that the concentration of

hydrophilic and lipophilic surfactant were very important parameter. The

release of caffeine as model hydrophilic substance from system studied; an

initial rapid release followed by a much slower rate of release was obtained.

Multiple w/o/w emulsion systems can be utilized as potential prolonged release

dosage forms. It was concluded that surfactant concentrations affected the

release rate.

Further in-vitro examinations such as

different type of oil phase or the different combinations of aqueous phase are

still required and it is recognized that further formulation studies are needed

to obtain the most stable formulations using Tetronic®908.

REFERENCES

1)

De Luca, M., Vaution, C.,

Rabarron, A., Seiller, M., Classification et obtention des emulsions multiples.

S.T.P. Pharma. Sci., 4(8):

679-687, 1988.

2)

De Luca, M., Grossiord, J.L., Médard, J.M., Vaution, C., A stable w/o/w

multiple emulsion.Cos. Toilet., 105: 65-69, 1990.

3)

Taelman,

M.C., Loll, P., Multiple emulsions in cosmetics. ICI Surfactants, Reprint,

RP112/94E, 1994.

4)

Garti, N., Aserin, A., Double emulsions

stabilized by macromolecular surfactants. Adv. Coll. Interface. Sci., 65:

37-69, 1996.

5)

Omotosho, J.A.,

6)

Ferreira, L.A.M., Doucet, J., Seiller, M.,

Grossiord, J.L., Marty, J.P., Wepierre, J., In vitro percutaneous absorption of

metronidazole and glucose: Comparison of o/w, w/o/w and w/o systems. Int. J.

Pharm., 121: 169-179, 1995.

7)

Silva-Cunha, A., Chéron, M., Grossiord,

J.L., Puisieux, F., Seiller, M., W/O/W multiple emulsions of insulin containing

a protease inhibitor and an absorption enhancer: Biological activity after oral

administration to normal and diabetic rats. Int. J. Pharm., 169: 33-44, 1998.

8)

Silva-Cunha, A., Grossiord, J.L., Seiller,

M., Multiple Emulsions: Pharmaceutical Potentiality, in: Grossiord JL: Seiller M (eds.), Multiple Emulsions:

Structure, Properties and Applications, Editions

9)

Jager-Lezer, N., Denine, R., Grossiord,

J.L., Wepierre, J., Rault, S., Seiller, M., Formulating multiple emulsions with

moisturizing actives. Cosm. Toilet., 111: 53-58, 1996.

10)

Omotosho, J.A., Whateley, T.L.,

11)

Okochi, H., Nakano, M., Basic studies on

formulation, method of preparation and characterization of

water-in-oil-in-water type multiple emulsions containing vancomycine. Chem.

Pharm. Bull., 44: 180-186, 1996.

12)

Doucet, O., Ferrero, L., Garcia, N., Zastrow, L., O/W emulsion

and w/o/w multiple emulsions: Physical characterization and skin

pharmacokinetic comparison in the delivery process of caffeine. Int. J. Cosm.

Sci., 20: 283-295, 1998.

13)

Okochi, H., Nakano, M., Preparation and

evaluation of w/o/w type emulsions containing vancomycin. Adv. Drug. Del. Rev.,

45: 5-26, 2000.

14)

Morishita, M., Matsuzawa, A., Takayama, K.,

Isowa, K., Nagai, T., Improving insulin enteral absorption using

water-in-oil-in-water emulsion. Int. J. Pharm., 172: 189-198, 1998.

15)

Gallarate, M.,

16)

Raynal, S., Grossiord, J.L., Seiller, M.,

Clausse, D., A topical w/o/w multiple emulsion containing several active

substances: formulation, characterization and study of release.J. Cont. Rel.,

26: 129-140, 1993.

17)

Garti, N., Double emulsions – Scope,

limitations and new achievements. Coll.

Surf. A: Physicochem. Engineer. Asp., 123-124:

233-246, 1997.

18)

Seiller, M., Grossiord, J.L., Silva-Cunha,

A., Multiple Emulsions: Pharmaceutical Potentiality, in: Grossiord JL: Seiller M (eds.), Multiple Emulsions:

Structure, Properties and Applications, Editions

19)

Schmolka, I.R., )

A comparison of block copolymer surfactant gels. J. Am. Oil. Chem. Soc.

(JAOCS), 68: 206-209, 1991.

20)

Clément, P., Laugel, C., Marty, J.P., In

vitro release of caffeine from concentrated w/o emulsions: Effect of

formulation parameters. Int. J. Pharm., 207: 7-20, 2000.

21)

Olivieri, L., Seiller, M., Bromberg, L.,

Besnard, M., Duong, T.N.L., Grossiord, J.L., Optimization of a thermally reversible

w/o/w multiple emulsion for shear-induced drug release. J. Cont. Rel., 88:

401-412, 2003.

22)

Ollivon, M., Potier-Guméry, L., Multiple

Emulsions: Pharmaceutical Potentiality, in: Grossiord JL: Seiller M (eds.), Multiple Emulsions:

Structure, Properties and Applications, Editions

23)

Aronson, M.P., Petko, M.F.,

Highly concentrated water in oil emulsions: Influence of electrolyte on their

properties and stability. J. Colloid Interface Sci., 159: 134-149, 1993.

24)

Kawashima, Y., Hino, T., Takeuchi, H.,

Niwa, T., Stabilization of water/oil/water multiple emulsion with hypertonic

inner aqueous phase. Chem. Pharm. Bull.

40: 1240-1246, 1992.

25)

Opawale, F.O., Burgess, D.J., Influence of

interfacial properties of lipophilic surfactants on water-in-oil emulsion

stability. J. Colloid. Interface. Sci., 197: 142-150, 1998.

26)

Kanouni, M., Rosano, H.L., Naouli, N., Preparation of a stable double emulsion (w1/o/w2):

Role of the interfacial films on the stability of the system. Adv. Coll. Interface. Sci., 99: 229-254,

2002.

27)

Matsumoto, S., Kıta, Y., Yonezawa, D.

J., An attempt at preparing water-in-oil-water multiple-phase emulsions. Coll.

Interface Sci., 57: 353-361, 1976.

28)

Magdassi, S., Frenkel, M., Garti, N., On the factors affecting the yield of preparation and

stability of multiple emulsions.J. Dispers. Sci. Tech., 5: 49-59, 1984.

29)

Laugel, C., Chaminade, P., Baillet, A.,

Seiller, M., Ferrier, D., Moisturizing substances entrapped in w/o/w emulsions:

Analytical methodology for formulation, stability and release studies. J. Cont.

Rel., 38: 59-67, 1996.

30)

Opawale, F.O., Burgess, D.J., Influence of

interfacial rheological properties of mixed emulsifier films on the stability

of water-in-oil-in-water emulsions. J. Pharm. Pharmacol., 50: 965-973, 1998.

31)

Jiao, J., Burgess, D.J., AAPS PharmSci., Rheology

and stability of water-in-oil-in-water multiple emulsions containing Span 83

and Tween 80. 5: Article 7, 2003 (http://www.pharmsci.org).

32)

33)

Omotosho, J.A., The effect of acacia,

gelatin and polyvinylpyrrolidone on chloroquine transport from multiple w/o/w

emulsions. Int. J. Pharm., 62: 81-84,

1990.

34)

Sever, S., Ocak (Tırnaksız), F.,

A topical w/o/w multiple emulsion prepared with Pluronic F-127 or Tetronic 908

as a hydrophilic surfactant: Formulation, characterization and release Studies,

in Yazan Y: Baser KHC (eds.), 4th

International Cosmetics Symposium, 7-8 June 2000, Istanbul, pp 212, 2000.

35)

Pays, K., Giermanska-Kahn, J., Pouligny,

B., Bibette, J., Leal-Calderon, F., Double emulsions: How does release occur?.J. Cont. Rel., 79: 193-200, 2002.

36)

Wen, L., Papadopoulos, K.D., Osmotic

pressure on water transport in w1/o/w2 emulsions. J.

Coll. Interface Sci., 235: 398-404, 2001.

37)

Jager-Lezer, N., Terrisse,

38)

Csóka, I., Erős,

39)

Terrisse,

40)

Muguet, V., Seiller, M., Barratt, G., Ozer,

O., Marty, J.P., Grossiord, J.L., Formulation of shear rate sensitive multiple

emulsions J. Cont. Rel., 70: 37-49, 2001.

41)

Kawashima, Y., Hino, T., Takeuchi, H.,

Niwa, T., Horibe, K., Rheological study of w/o/w emulsion by a cone-and-plate

viscometer: Negative thixotropy and shear-induced phase inversion. Int. J.

Pharm., 72: 65-77, 1991.

42)

Magdassi, S., Garti, N., Release of

electrolytes in multiple emulsions: Coalescence and breakdown or diffusion

through oil phase?.

Coll. Surf., 12: 367-373, 1984.

43)

Wen, L., Papadopoulos, K.D., Visualization

of Water Transport in W1/O/W2 Emulsions.Coll. Surf. A:Physicochem

44)

Clément, P., Laugel, C., Marty, J.P.,

Influence of three synthetic membranes on the release of caffeine from

concentrated w/o emulsions. J. Cont. Rel., 66: 243-254, 2000.

45)

Attwood, D., Collett, J.H., O’Connor,

46)

Dong, J., Chowdhry, B.Z., Leharne, S.A.,

Surface activity of poloxamines at the interfaces between air-water and

hexane-water. Coll. Surf. A: Physicochem

47)

Omotosho, J.A., Whateley, T.L.,

48)

Geiger, S., Tokgoz, S., Fructus, A.,

Jager-Lezer, N., Seillere, M., Lacombe, C., Grossiord, J.L., Kinetics

of swelling-breakdown of a w/o/w multiple emulsion: Possible mechanisms for the

lipophilic surfactant effect. J. Cont. Rel., 52: 99-107, 1998.

49)

Geiger, S., Jager-Lezer, N., Tokgoz, S.,

Seiller, M., Grossiord, J.L., Characterization of the mechanical properties of

a water/oil/water multiple emulsion oily membrane a micropipette aspiration

technique.Coll. Surf. A: Physicochem. Engineer. Asp.,

157: 325-332, 1999.

50)

Yan, J., Pal, R.J., W/O/W multiple

emulsions: A review of release mechanisms by break-up of the oily membrane. J.

Memb. Sci., 190: 79-91, 2001.

51)

Grossiord, J.L., Seiller, M., W/O/W

multiple emulsions: A review of release mechanisms by break-up of the oily

membrane. STP Pharma. Sci., 11: 331-339, 2001.

52)

Omotosho, J.A., Whateley, T.L., Law, T.K.,

53)

Sela, Y., Magdassi, S.,

54)

Magdassi, S., Garti, N., A kinetic model

for release of electrolytes from w/o/w multiple emulsions. J. Cont. Rel., 3:

273-277, 1986.

Published by the Canadian Society for Pharmaceutical Sciences.

Copyright © 1998 by the Canadian

Society for Pharmaceutical Sciences.

http://www.cspscanada.org

CSPS Home | JPPS

Home | Search

| Subscribe to JPPS