|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ch E 416 – Assignment 8

Solutions

(1) Batch Distillation

(2) Multicomponent

Distillation (shortcut method)

2.1

Minimum number of trays

using the Fenske equation From

HYSYS where LK = light key (n-butane), and HK = heavy key (i-Pentane) Recoveries

of LK and HK components in distillate are 98% and 2%, respectively

2.1

Minimum reflux ratio using

the Underwood method Relative

volatilities (with respect to isopentane) and feed flow rates of the

components

With

n-butane as the light key and isopentane the heavy key component, the

assumption of no distribution of components lighter than the light key and

heavier than the heavy key component means that the distillate flow component

rates and compositions are as follows (recovery of LK 98%, of heavy key 2% in

distillate)

Solve the equation

For the value of Use of fzero of Matlab yields:

We use

From which, Rmin = 0.6597 2.3

Minimum reflux ratio if isobutane is the light key; heavy key unchanged Assuming that lighter than light key and heavier than heavy key do not distribute, all component flow rates in the distillate are known except that of n-butane. From the equations,

There are three equations and three unknowns (Rmin, n-butane flow rate in distillate, and D). Simultaneous solution yields: Rmin = 0.5944 2.4

Design using HYSYS You should get: Minimum number of trays = 5.7 Actual number of trays = 17.4 Optimal Feed stage = 8.3 See

A8.hsc (3) Multicomponent Distillation (Rigorous method)

3.1 Inputs: Number of trays = 18, with total condenser and default reboiler Distillate rate = 0.6052 Reflux ratio = 0.65 You should get:

CMO is valid for this mixture of similar hydrocarbons 3.2 Switch specs of distillate rate with recovery

spec of the LK in distillate You should get a new distillate rate of 0.629

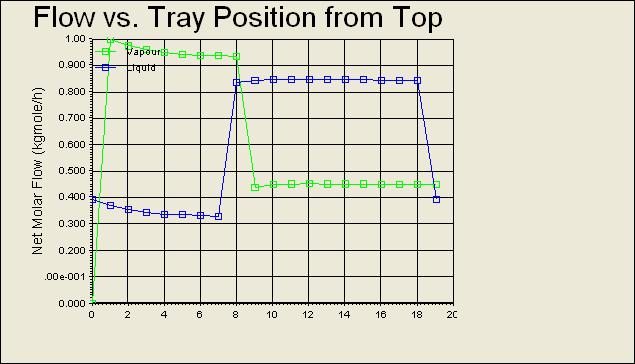

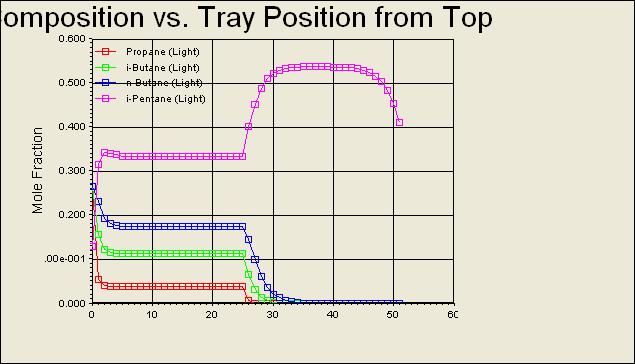

kmol/h 3.3 In HYSYS, for example, using a distillate rate = 0.45, a reflux ratio = 0.4 and number of trays = 50 with feed on the 25th tray, a pinch condition of class 1 results. See figure below:

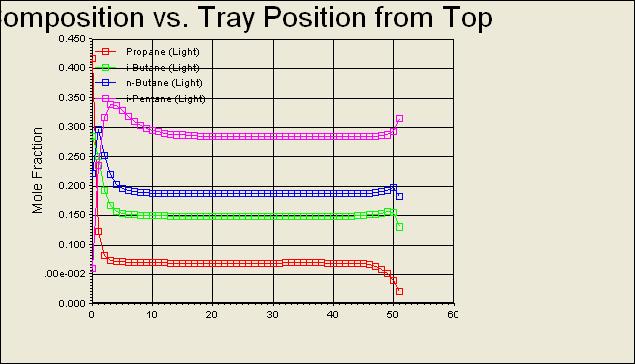

3.4 In HYSYS, for example, using a distillate rate = 0.75, a reflux ratio = 0.3 and number of trays = 50 with feed on the 25th tray, a pinch condition of class 2 results. See figure below.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||